停止让宝贵的渣打浪费! 我们的尖端甘蔗渣木炭制造机将这种丰富的副产品转换为具有无与伦比效率的高利润可持续产品. 加入绿色能源革命,同时提高您的利润! WEIWA集团为客户提供一流的解决方案设计, 安装指导和其他售后服务.

甘蔗工业的背景

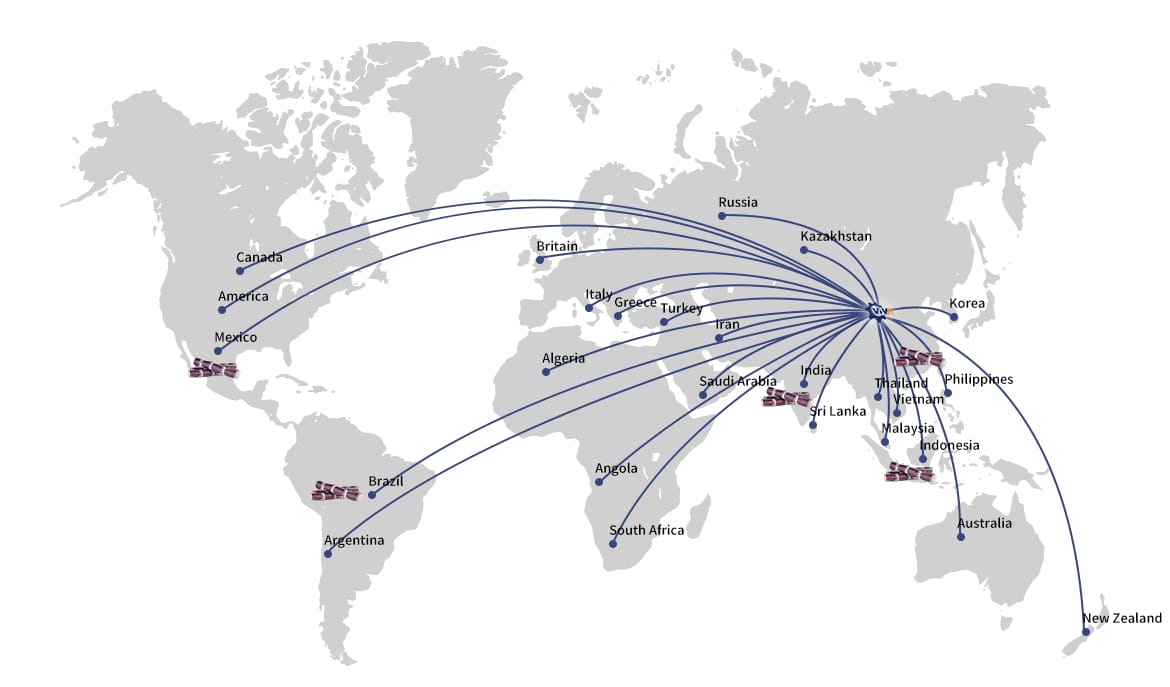

甘蔗甘蔗渣, 甘蔗加工的副产品, 在全球范围内广泛使用. 许多国家种植了大片甘蔗, 例如 巴西, 印度, 泰国, 巴基斯坦, 墨西哥, 印度尼西亚 等等.

谁需要甘蔗甘蔗制造机器?

- 糖厂 - 从渣打废物中获利

- 木炭生产商 - 扩展产品范围

- 农民 - 制作土壤改善的生物炭

- 废物到能量公司 - 可持续燃料生产

新解决方案:甘蔗渣炭化机

从收获到最终处理, 最终适合木炭生产的甘蔗废物主要包括:

甘蔗叶: 甘蔗叶是收获期间通常生产的废物.

甘蔗上衣: 他们代表 15 到 25% 植物的空中部分. 它们通常由绿叶组成, 束鞘, 和可变数量的未成熟甘蔗.

甘蔗甘蔗渣 (稻草): 渣酱是糖汁提取后保留的纤维材料,构成约30-40 wt % 甘蔗. 大约 280 每吨甘蔗产生的渣酱.

为什么甘蔗渣适合制作木炭?

将甘蔗甘蔗渣转换为生物木炭的可行性很有希望, 在原材料特征和市场趋势的支持下.

原材料分析: 甘蔗废物的自然特征

- 丰富: 渣饼是一种甘蔗加工的易用废物, 确保木炭生产的一致且充足的供应.

- 更新性: Bagasse是一种可再生资源. 这使甘蔗木炭成为可持续的替代燃料.

- 高能量含量: 甘蔗渣的高纤维素 (45%), 半纤维素 (32%), 木质素 (17%) 内容, 低灰分含量有助于其高能量含量, 使其适合转换为高质量的木炭.

市场分析: 对生物炭的兴趣越来越大

- 生物能量的普及: 生物能是由生物材料制成的可再生能源. 它在燃烧过程中几乎没有环境污染. 越来越强调环境保护和可持续发展, 生物能源正在成为越来越受欢迎的替代能源. 这驱动了对生物木炭的需求,例如甘露木炭和木炭.

- 生物炭的跨行业应用: 各种行业正在探索生物炭在其域中的应用. 例如, 在农业中, 生物炭用于增强土壤质量, 在牲畜种植中, 它用作饲料补充剂. 行业, 农业, 牲畜种植, ETC. 都对生物炭的环保和可持续性表现出兴趣.

如何使用甘蔗渣木炭制造机?

购买甘蔗木炭机器后, 您准备从甘蔗渣拿起木炭生产过程. 甘蔗渣木炭机主要基于高温碳化的原理. 这是将甘蔗废物转化为木炭的方式:

01 预处理

- 压碎 (选修的): 压碎系统将甘蔗渣拿到目标尺寸 (小于20mm).

- 烘干 (选修的): 干燥系统将甘蔗甘蔗加工的水分含量少于 15%.

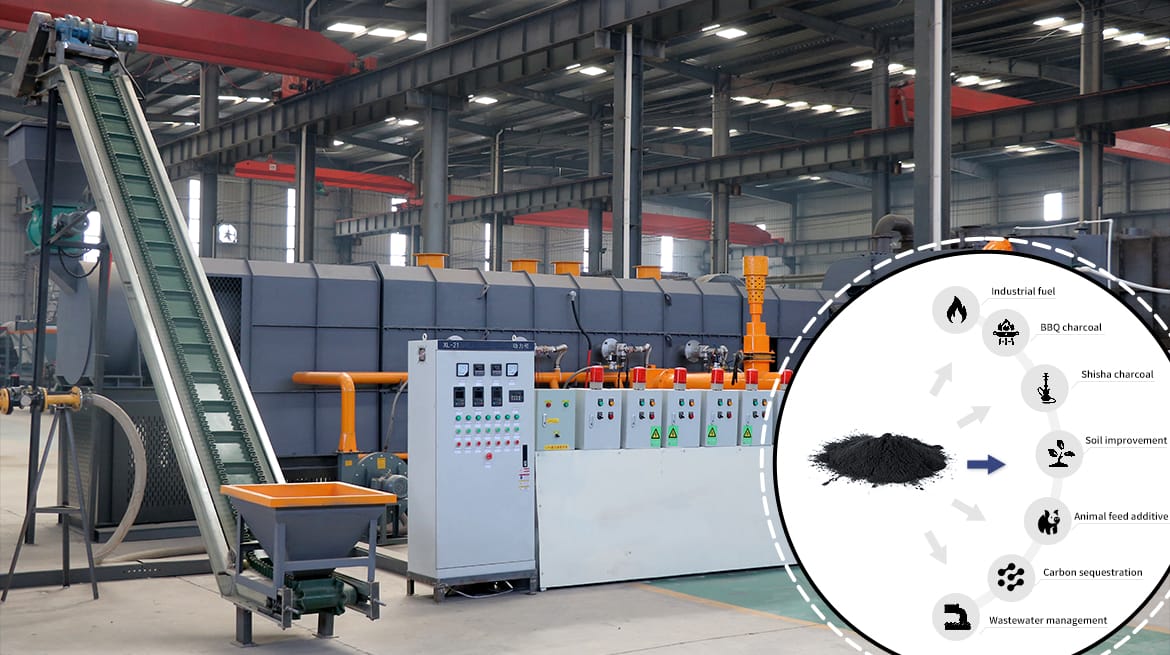

02 碳化

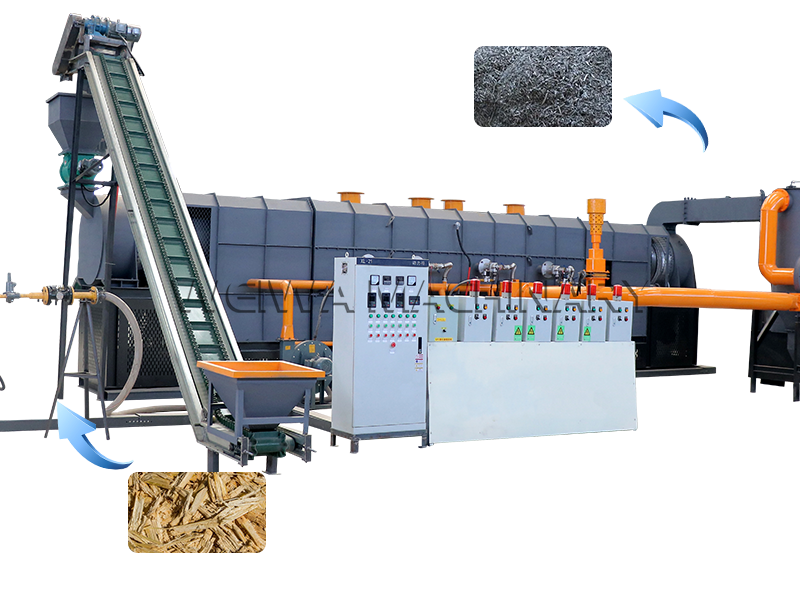

- 进食: 甘蔗渣通过通过传送带自动送入炉子, 螺丝喂食器或Z带.

- 碳化: 加热主炉后, 温度逐渐上升. 初始温度有助于散发出甘蔗蔗渣中的一些水分. 当温度达到 250 摄氏摄氏度, 脱甲基开始. 可燃气开始产生. 在 280 摄氏摄氏度, 放热反应开始. 碳氢化合物分子分成较小的碳分子和氢. 木炭开始生产. 随着温度的命中 450 摄氏摄氏度, 芳香环化合物开始反应.

03 排放

- 甘蔗木炭 : 通过三个阶段的水冷却排放器, 甘蔗木炭下面 45 收集摄氏摄氏度.

- 焦油 & 木醋收集 (选修的): 通过冷凝器, 焦油 (生物质油) 和木醋分开并分别收集.

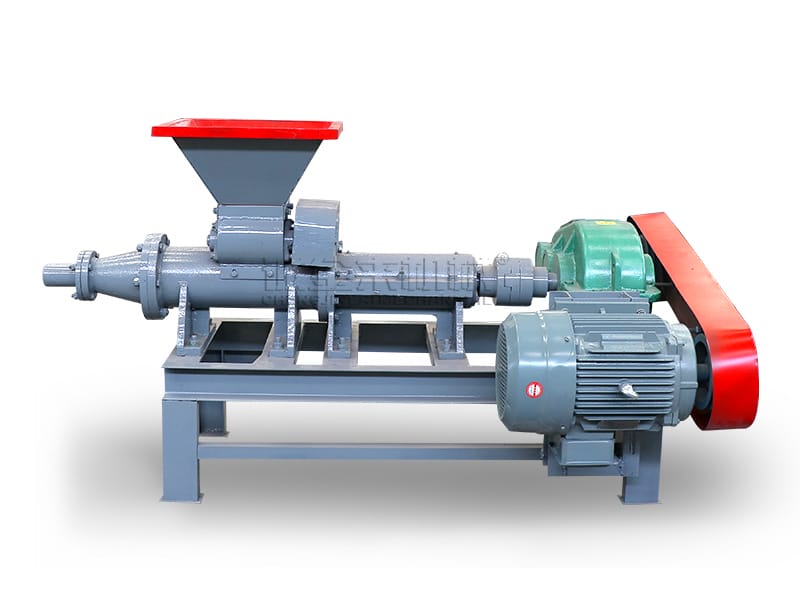

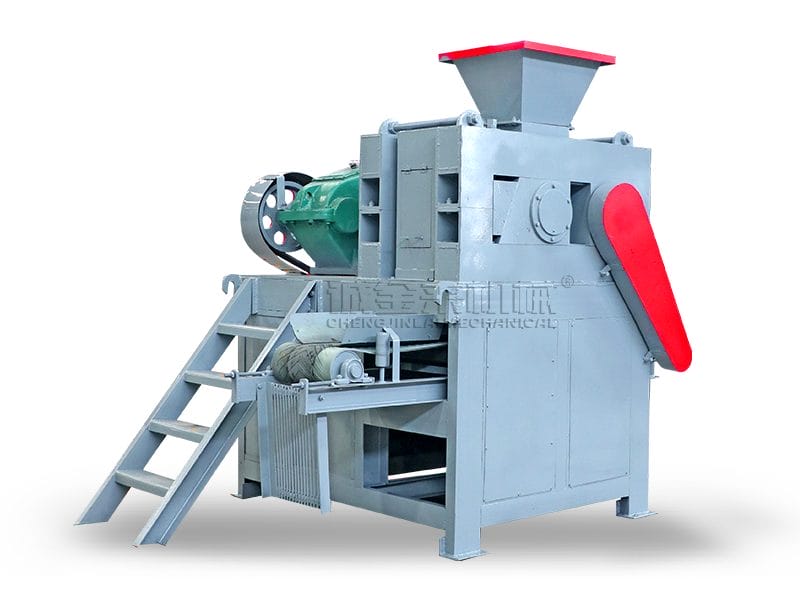

- 甘蔗木炭煤片制作 (选修的): 被甘蔗木炭煤石机处理后, 可以将木炭的原始形状变成所需的形状, 例如圆形, 正方形, 戳, ETC.

04 可燃气体回收

- 凝结和去除硫处理后, 可燃气可以回收并重复使用.

- 我们还可以将碳化炉的多余热量引入干衣机中以回收可燃气体, 从而为干衣机节省了燃料.

05 废气处理

- 排放气体由喷雾塔处理, 水幕除外塔, 和冷却塔. 处理后的排放气体符合欧盟排放标准.

- WEIWA组提供高标准的定制排气处理系统.

甘蔗制造机的功能

配备警报设备

PLC电柜有一个警报设备, 并且将有一个警报显示和一些电气故障的警报.

与防爆炸的水密封

可燃管道上有一个防爆炸的水密封 (为了防止设备中可燃气体的异常压力)

频率粉丝指南

所有管道中气体的方向由风扇领导 (风扇是可变频率), 当管道被阻止时,它将显示在PLC上.

高热效率

该材料没有与烟道气体接触,也不会被热空气污染.

良好的节能效果

该设备的热利用率较高, 使用前变换器的空气使用可以有效地提高热效率 5-10%, 节能效果很好.

如何从甘蔗渣木炭制造机器中获利?

生产的甘蔗甘蔗渣木炭煤球可以带来良好的经济利益,因为它们在不同的行业中的广泛应用. 投资者可以将它们出售给相关行业以获利.

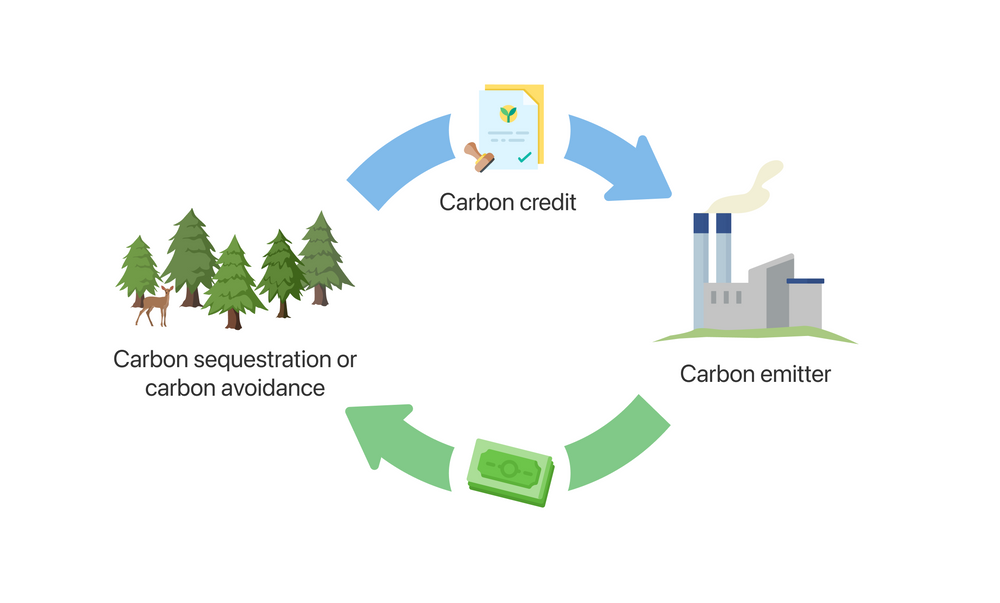

保证获得碳信用交易

- 高碳含量

- 100% 自然和环保的

- 捕获大量二氧化碳并改善碳足迹

- 用于市场交易, 例如碳信用额, 碳补偿

高质量的甘蔗木炭产量

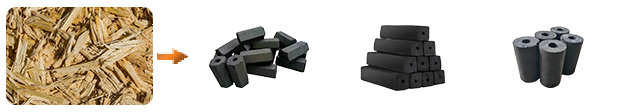

通过使用甘蔗渣木炭制造机, 我们可以获取最重要的最终产品, 甘蔗渣木炭. 木炭可以进一步加工到水烟或烧烤木炭中, 两者都有很高的价值,可以在许多领域应用. 它是水烟木炭或烧烤木炭生产的最合适的机器.

烧烤木炭

- 高碳卡路里

- 低烟

- 低灰分含量

- 长时间燃烧的时间

- 果味木质香气

水烟木炭 /shisha木炭

- 稳定温度

- 高硬度

- 低烟雾量

- 长时间燃烧的时间

- 果味木质香气

土壤改善

- 80% 微孔结构以改善土壤曝气和排水

- 提供一些微量元素, 例如钾, 镁, 锌

- 碱度和离子交换有助于调整土壤pH并节省肥料成本

政策补贴申请

一些国家或地区为使用生物质能源提供补贴或税收优惠, 例如欧盟的“绿色新政”或中国的可再生能源支持政策.

相关产品

甘蔗渣木炭制造机也可以处理不同的原材料

微信

微信

+8613838093177

+8613838093177