椰子壳制造机器 是回收废物椰子壳的高效机器. 当您打算回收这些椰子壳时, 您不仅需要简单的设备提供商. 您需要一个能够提供适当解决方案的专家. 欢迎从WEIWA机械组获取碳化解决方案.

椰子行业的背景

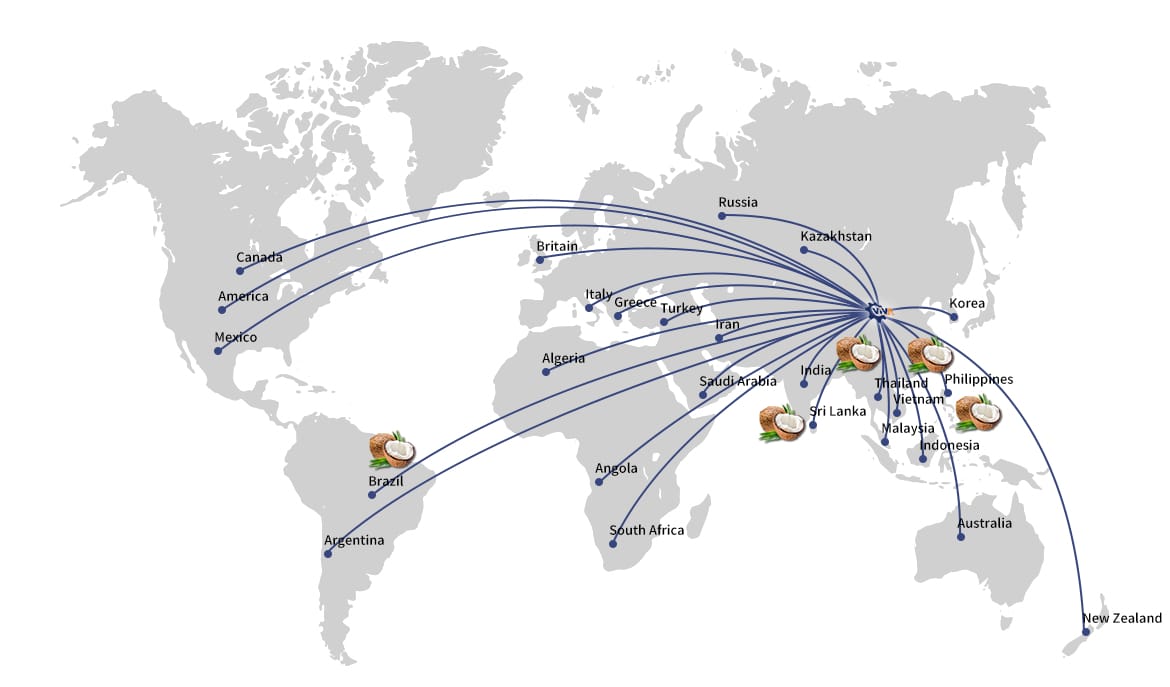

生产国

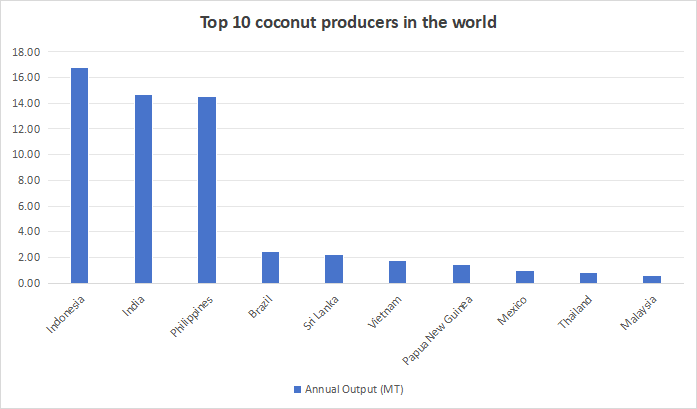

椰子树生长超过 80 国家. 这里, 我们列出顶部 10 椰子生产的国家. 印度尼西亚, 菲律宾和印度 这些国家的椰子生产领先. 这三个国家的椰子出口占 70% 全球椰子出口. 请参阅椰子生产数据.

椰子壳管理

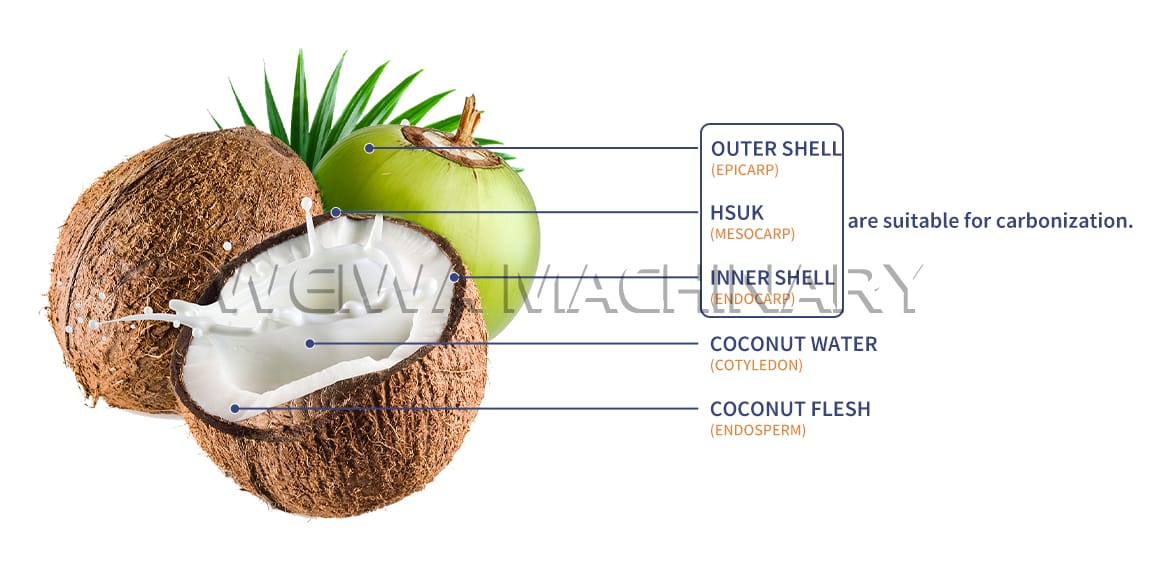

在这些椰子废物中, 使用椰子壳木炭制造机回收椰子外壳是主要解决方案WEIWA Group提供的. 大约 50 每年都会丢弃百万椰子壳. 垃圾填埋或丢弃椰子壳会产生温室气体并污染环境. 椰子壳富含纤维素, 半纤维素和木质素. 它实际上具有很高的能量价值. 这是一种需要紧急回收的浪费.

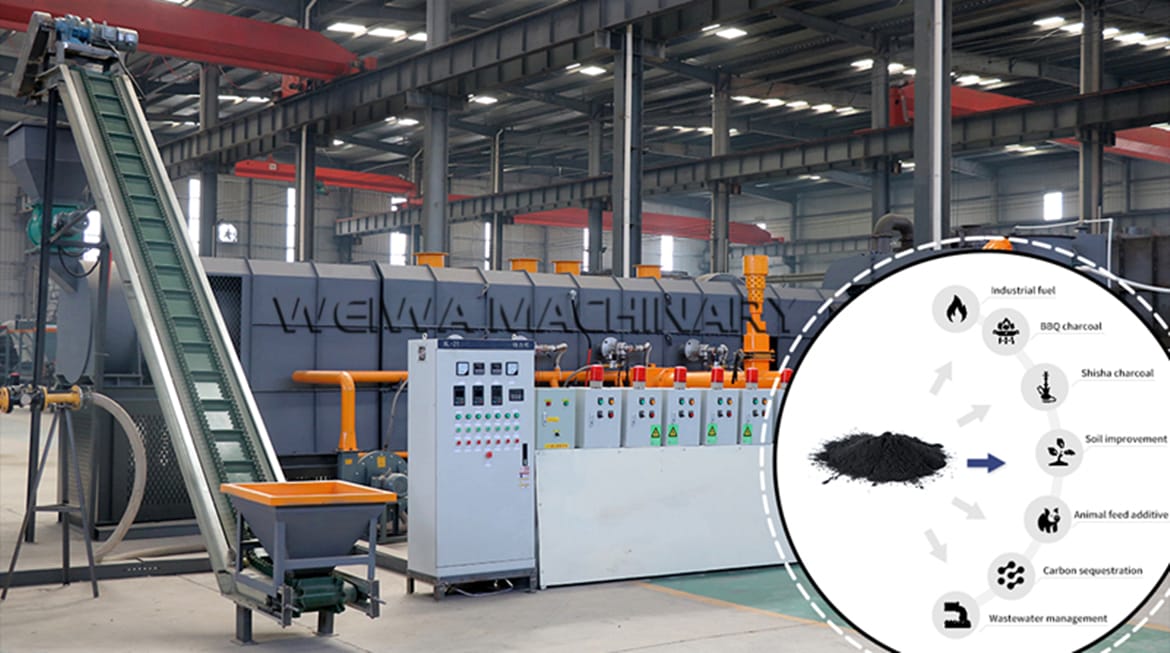

如何使用椰子壳制造机器

整个椰子壳回收过程主要包括压碎, 烘干, 进食, 碳化, 排放, 可燃气体回收, 废气处理, 和椰子壳的煤球生产。

01 预处理

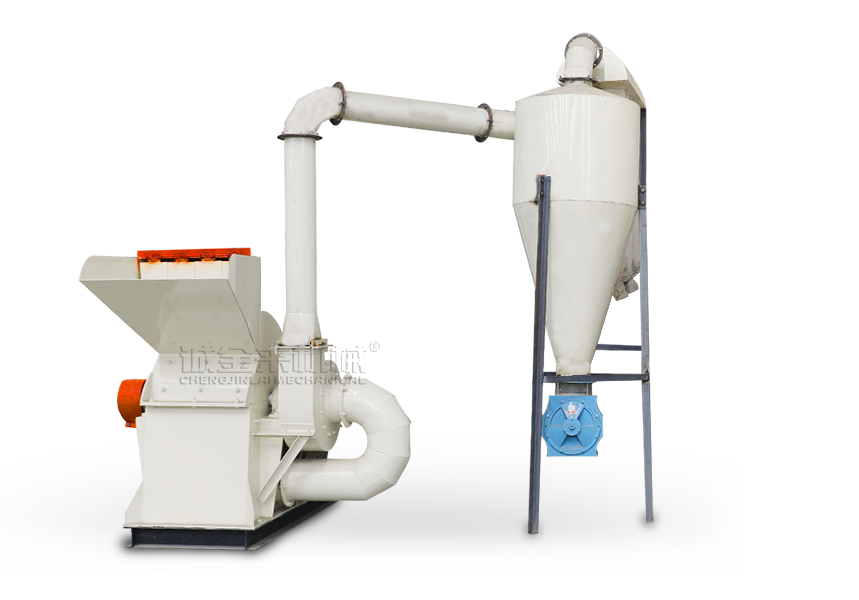

- 压碎 (选修的): 压碎系统将椰子壳处理成目标尺寸 (小于20mm).

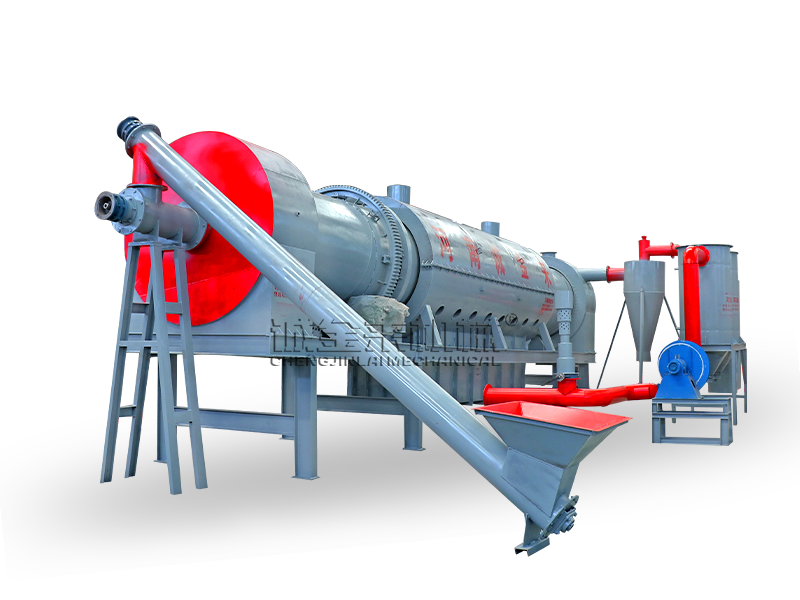

- 烘干 (选修的): 干燥系统将椰子壳处理的水分含量少于 15%.

02 碳化

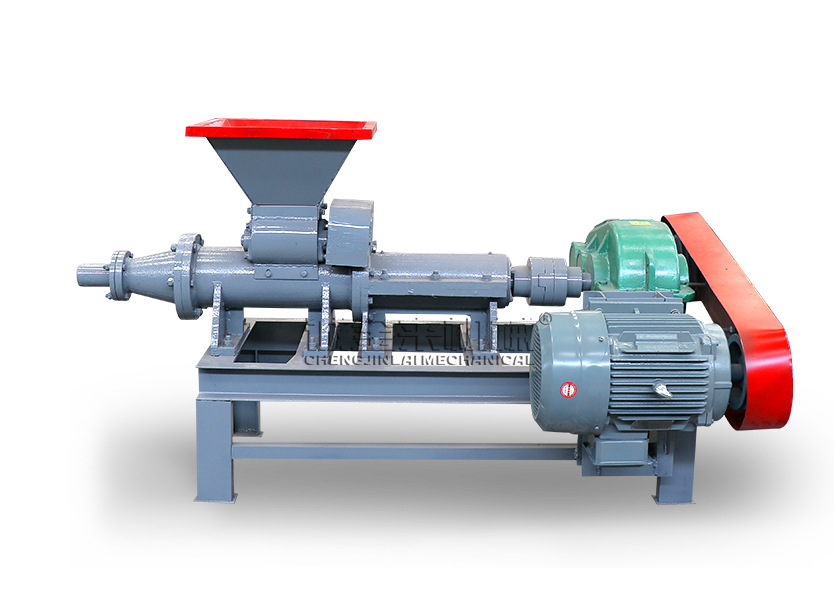

- 进食: 椰子贝壳通过传送带自动送入炉子, 螺丝喂食器或Z带.

- 碳化: 加热主炉后, 温度逐渐上升. 初始温度有助于干燥椰子壳中的一些水分. 当温度达到 250 摄氏摄氏度, 脱甲基开始. 可燃气开始产生. 在 280 摄氏摄氏度, 放热反应开始. 碳氢化合物分子分成较小的碳分子和氢. 木炭开始生产. 随着温度的命中 450 摄氏摄氏度, 芳香环化合物开始反应.

03 排放

- 椰子壳木炭: 通过三个阶段的水冷却排放器, 椰子壳木炭下面 45 收集摄氏摄氏度.

- 焦油 & 木醋收集 (选修的): 通过冷凝器, 焦油 (生物质油) 和木醋分开并分别收集.

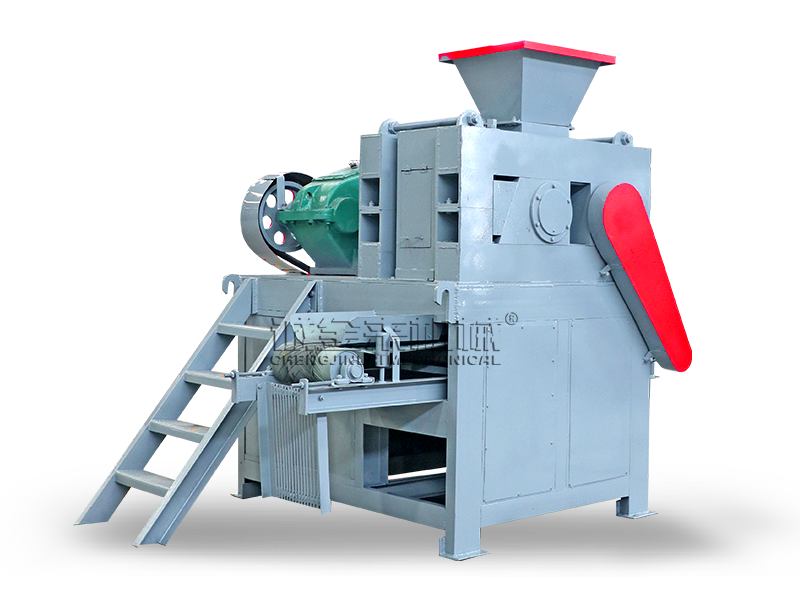

- 椰子壳木炭煤片制作 (选修的): 被椰子壳木炭煤片机处理后, 可以将木炭的原始形状变成所需的形状, 例如圆形, 正方形, 戳, ETC.

04 可燃气体回收

- 凝结和去除硫处理后, 可燃气可以回收并重复使用.

- 我们还可以将碳化炉的多余热量引入干衣机中以回收可燃气体, 从而为干衣机节省了燃料.

05 废气处理

- 排放气体由喷雾塔处理, 水幕除外塔, 和冷却塔. 处理后的排放气体符合欧盟排放标准.

- WEIWA组提供高标准的定制排气处理系统.

椰子壳制造机的功能

配备警报设备

PLC电柜有一个警报设备, 并且将有一个警报显示和一些电气故障的警报.

与防爆炸的水密封

可燃管道上有一个防爆炸的水密封 (为了防止设备中可燃气体的异常压力)

频率粉丝指南

所有管道中气体的方向由风扇领导 (风扇是可变频率), 当管道被阻止时,它将显示在PLC上.

高热效率

该材料没有与烟道气体接触,也不会被热空气污染.

良好的节能效果

该设备的热利用率较高, 使用前变换器的空气使用可以有效地提高热效率 5-10%, 节能效果很好.

如何从椰子壳制造机器中获利

椰子壳到木炭是一种循环经济解决方案. 椰子壳转化为生物质木炭资源. 生物质木炭可以应用于椰子壳种植行业和食品加工行业. 这允许可持续发展和真正的闭环解决方案.

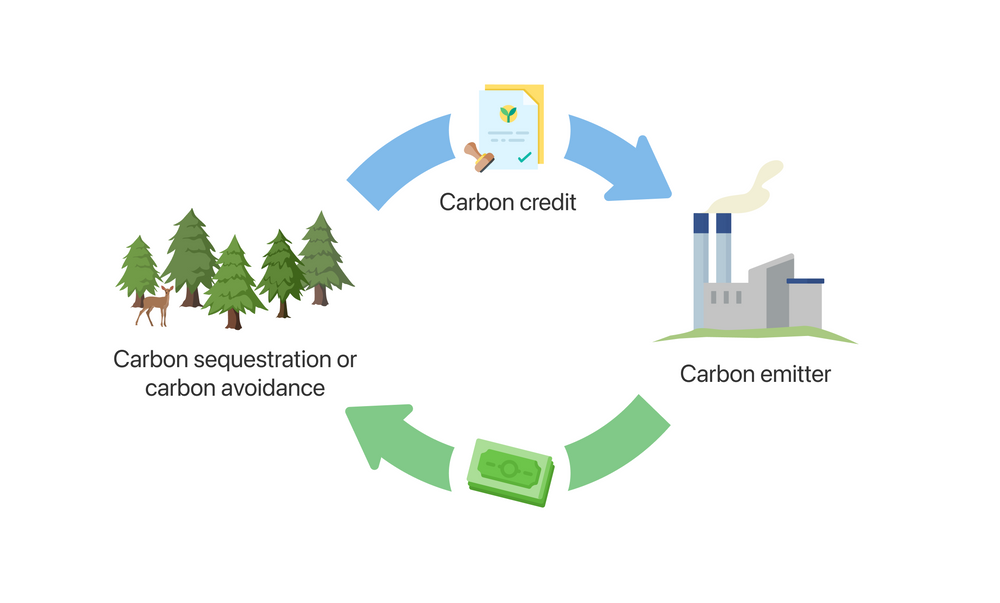

保证获得碳信用交易

- 碳信用交易: 生物炭制造机的量化碳还原效应产生碳信用. 生物炭生产商可以在碳市场上将其出售给碳排放过多的公司.

- 碳固存: 生物质的碳含量来自大气中2 被光合作用吸收。生物炭碳化设备稳定地将此碳存储在生物炭中. 这避免了生物质自然降解的碳排放.

土壤改善

- 80% 微孔结构以改善土壤曝气和排水

- 提供一些微量元素, 例如钾, 镁, 锌

- 碱度和离子交换有助于调整土壤pH并节省肥料成本

高质量的椰子壳生物炭输出

通过使用椰子壳制造机器, 我们可以获取最重要的最终产品, 椰子壳木炭. 木炭可以进一步加工到水烟或烧烤木炭中, 两者都有很高的价值,可以在许多领域应用. 它是水烟木炭或烧烤木炭生产的最合适的机器.

烧烤木炭

- 低烟

- 低灰分含量

- 长时间燃烧的时间

- 果味木质香气

- 高碳卡路里

水烟木炭 (Shisha木炭)

- 高硬度

- 低烟雾量

- 长时间燃烧的时间

- 果味木质香气

- 稳定温度

政策补贴申请

一些国家或地区为使用生物质能源提供补贴或税收优惠, 例如欧盟 “绿色新交易” 或中国的可再生能源支持政策.

椰子壳木炭成分分析

| 不. | 1# |

| 种类 | 椰子壳 |

| 总水分mt% | 9.1 |

| 分析水百分比 | 4.19 |

| 干燥基灰广告% | 0.18 |

| 挥发性物质为vd% | 6.95 |

| 固定碳FCAD% | 88.68 |

| 硫含量以干燥的基础st.d% | 0.09 |

| oking特性1-8crc | |

| 新的国家标准热量表干燥基础高热量kcal/kg | 7277 |

| 新的国家标准热量表方法获得基本低热量值kcal/kg | 6724 |

**℃从水和油中出来, 最高温度**℃上述数据仅供参考.

相关产品

微信

微信

+8613838093177

+8613838093177