介紹

At Weiwa Machinery, 我們專門研究高級木炭生產解決方案, and our 連續式炭化爐 is revolutionizing how industries utilize agricultural waste like 稻殼. We warmly welcome Indonesian clients to visit our factory and observe firsthand how this technology transforms rice husk into high-quality 生物炭—a sustainable resource for agriculture, energy, 還有更多.

This blog will explore the science behind continuous carbonization, its advantages over traditional methods, and the impressive results from our recent trials.

What Is a 連續碳化爐?

The Science Behind Continuous Carbonization

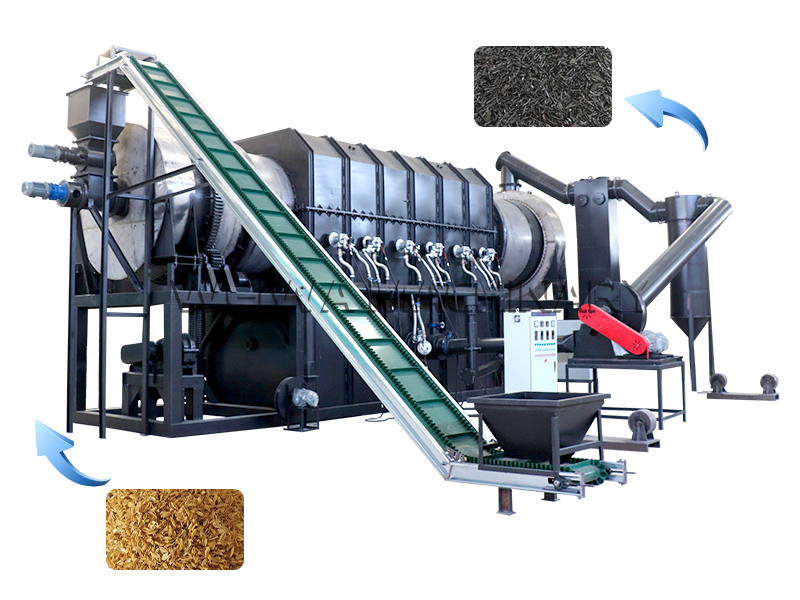

a連續式炭化爐 is an automated system designed to convert biomass (例如, 稻殼, 椰子殼, 木屑) into charcoal through pyrolysis—a thermal decomposition process in an oxygen-limited environment. Unlike batch-type furnaces, our continuous system operates non-stop, ensuring higher efficiency, lower energy consumption, and consistent output.

Key Components of Weiwa’s Continuous Carbonization Furnace

- Feeding System: Automatically supplies rice husk into the furnace.

- Pyrolysis Chamber: Heats biomass to 400–600°C, breaking it down into biochar, syngas, and tar.

- Gas Recycling Unit: Reuses combustible gases to fuel the furnace, reducing external energy needs.

- Discharge System: Cooled biochar is collected without interrupting production.

Why Rice Husk Is the Ideal Raw Material for Biochar

Turning Waste into Wealth

稻殼, a byproduct of rice milling, is abundant in Indonesia but often discarded or burned openly. 我們的continuous carbonization furnace for rice husk unlocks its potential by converting it into:

- Biochar: Enhances soil fertility and carbon sequestration.

- Renewable Energy: Syngas can power generators or heat the furnace.

- Industrial Applications: Used in metallurgy, 水過濾, and cosmetics.

Environmental and Economic Benefits

By processing rice husk into biochar, Indonesian farmers and factories can:

- Reduce waste and pollution from open burning.

- Generate additional income from biochar sales.

- Meet sustainability goals with carbon-negative production.

Weiwa’s Continuous Carbonization Furnace in Indonesia: Test Results

Real-World Performance Metrics

During a recent trial with Indonesian partners, our furnace achieved:

- 95% Carbonization Efficiency: Nearly all rice husk was converted into usable products.

- 24/7 Operation: Minimal downtime with automated controls.

- Low Emissions: Compliant with Indonesia’s environmental standards.

客戶反饋

Indonesian clients praised the furnace’s low labor requirements和fast ROI (return on investment), citing a 40% reduction in operational costs compared to traditional kilns.

Visit Weiwa’s Factory: See the Technology in Action!

Why Tour Our Facility?

We invite Indonesian clients to:

- Observe live demonstrations of rice husk carbonization.

- Discuss customization options for local needs.

- Network with our engineering team for technical support.

How to Arrange a Visit

Contact our sales team to schedule a factory tour and receive a free sample of rice husk biochar.

關於Weiwa機械

WEIWA機械 is a leading manufacturer of charcoal and biomass processing equipment, 結束 30 多年的經驗. 我們的連續碳化爐 are exported to 30+ 國家, offering innovative, eco-friendly solutions for waste recycling and energy recovery.

- Phone: +8613838093177

- 電子郵件: info@cjlmachinegroup.com

微信

微信