Introduction to Charcoal Briquette Machines

Charcoal briquette machines, 例如 charcoal extruders, 對於將廢棄生物質或煤塵轉化為高密度燃料棒至關重要. 這些機器因其成本效益和環境效益而在烏幹達廣泛用於家庭和工業應用.

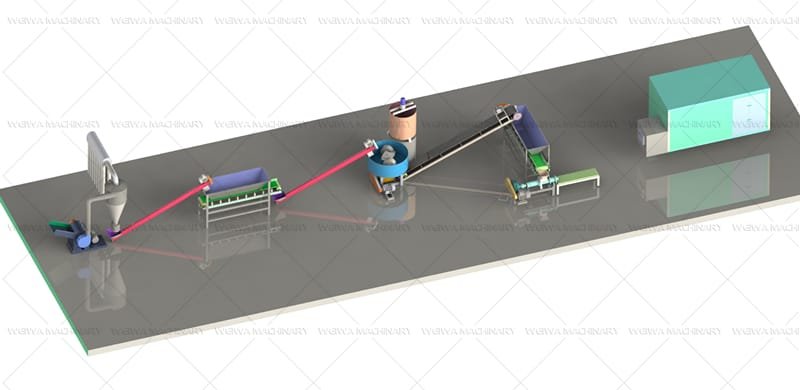

在WEIWA機械, we specialize in manufacturing high-performance charcoal extruder machines, sawdust extruder machines, 和 ball briquette machines designed for efficiency and durability. 在這個部落格中, we’ll explore the working principles of these machines and share insights from a recent test run of our equipment.

How Does a Charcoal Extruder Machine Work?

Key Components & Process

a木炭擠出機 compresses raw materials (木炭粉, 煤塵, 或生物質) 在高壓下, forcing them through a mold to form solid briquettes. The process involves:

- Feeding System: Raw materials are fed into the machine’s hopper.

- 壓縮 & 擠壓: A screw conveyor pushes the material into a compression chamber, where high pressure forms dense rods.

- Cutting & 烘乾: The extruded rods are cut to size and dried for optimal combustion.

We can also customize the 生產線 according to the customers’ 要求.

Why Choose a Rod Briquette Machine?

Rod-shaped briquettes offer several advantages:

- Higher density for longer burning time.

- Lower smoke emissions compared to loose charcoal.

- Easier storage & 運輸 due to uniform shape.

Weiwa’s Charcoal Extruder Test Run: Key Findings

Test Setup & Parameters

We conducted a real-world test run of our 木炭擠出機 under typical Ugandan operating conditions. The test focused on:

- Production capacity (公斤/小時)

- Energy efficiency (power consumption)

- Briquette quality (density, 耐用性, and burn time)

性能結果

Our machine demonstrated:

- High output efficiency, producing 500-1000 公斤/小時 depending on material moisture.

- 低功耗, making it cost-effective for small and medium businesses.

- Consistent briquette quality, with dense, crack-free rods ideal for cooking and industrial use.

Factors Affecting Charcoal Extruder Machine Price in Uganda

When evaluating charcoal making machine prices, consider:

- Machine capacity (small-scale vs. industrial models).

- Material compatibility (木炭灰塵, 木屑, 或農業廢物).

- After-sales support, including installation and maintenance.

Weiwa Machinery offers 競爭價格 without compromising quality, ensuring a strong return on investment for Ugandan customers.

為什麼選擇 WEIWA機械?

With 超過 30 多年的經驗, Weiwa Machinery is a trusted name in briquette machine manufacturing. 我們的expert technical team provides:

- Customized solutions tailored to your production needs.

- On-site installation & training for smooth operation.

- Reliable after-sales support, including spare parts and troubleshooting.

Whether you need a 木炭擠出機, 棒式壓球機, or full production line, Weiwa delivers 耐用的, high-performance equipment at a fair price.

聯繫我們

WhatsApp/WeChat/Tel:+86 13838093177

電子郵件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177