Stop letting valuable bagasse go to waste! Our cutting-edge Sugarcane Bagasse Charcoal Making Machine converts this abundant byproduct into high-margin sustainable products with unmatched efficiency. Join the green energy revolution while boosting your profits! WEIWA Group provides customers with first-class solution design, installation guidance and other after-sales services.

Background of Sugarcane Industry

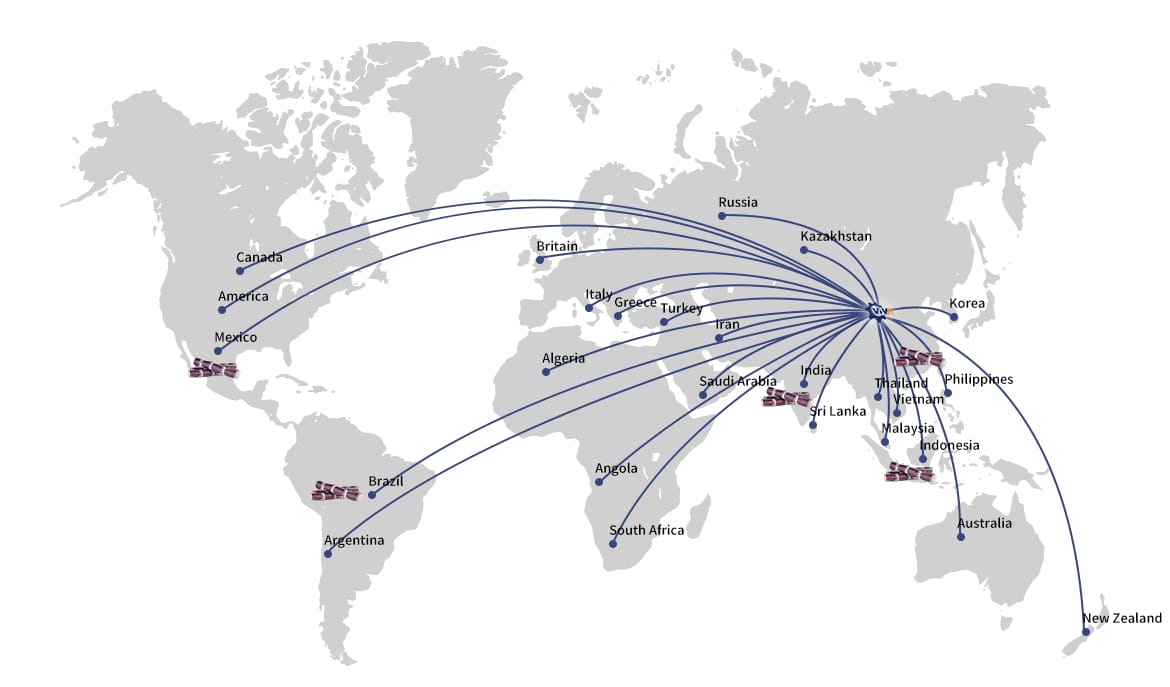

Sugarcane bagasse, a byproduct of sugarcane processing, is abundantly available worldwide. Large areas of sugarcane are planted in many countries, 例如 Brazil, 印度, 泰國, 巴基斯坦, 墨西哥, 印度尼西亞 and so on.

Who Needs Sugarcane Bagasse Charcoal Making Machine?

- Sugar mills – Profit from bagasse waste

- Charcoal producers – Expand product range

- Farmers – Make biochar for soil improvement

- Waste-to-energy companies – Sustainable fuel production

New solutions:甘蔗渣木炭製造機

From the harvest to the final processing, the resulting sugarcane waste which is suitable for charcoal production mainly includes:

Sugarcane leaves: Sugarcane leaves are a waste product usually produced during harvest.

Sugarcane tops: They represent 15 到 25% of the aerial part of the plant. They generally consist of green leaves, bundle sheaths, and variable amounts of immature cane.

Sugarcane bagasse (稻草): Bagasse is the fibrous material that remains after the extraction of sugar juice and constitutes about 30–40 wt % of the sugarcane. Around 280 kg of bagasse is generated from every ton of sugarcane.

Why Sugarcane Bagasse is Suitable for Making Charcoal?

The feasibility of converting sugarcane bagasse into bio charcoal is promising, supported by raw material characteristics and market trends.

Raw Material Analysis: Sugarcane Waste’s Natural Characteristics

- Abundance: Bagasse is a readily available waste product from sugarcane processing, ensuring a consistent and ample supply for charcoal production.

- Renewability: Bagasse is a renewable resource since sugarcane is a fast-growing crop that is harvested annually. This makes sugarcane charcoal a sustainable alternative fuel.

- High energy content: Bagasse’s high cellulose (45%), hemicellulose (32%), lignin (17%) 內容, and low ash content contribute to its high energy content, making it suitable for conversion into high-quality charcoal.

Market Analysis: Growing Interest in Biochar

- Rising popularity for bio-energy: Bioenergy is renewable energy made from biological materials. It has little environmental pollution during combustion. With the growing emphasis on environmental protection and sustainable development, bioenergy is becoming an increasingly popular alternative energy source. This drives the demand for bio charcoal such as sugarcane charcoal and wood charcoal.

- Cross-industry applications of biochar: Various industries are exploring the applications of biochar within their domains. For instance, in agriculture, biochar is used to enhance soil quality, while in livestock farming, it serves as a feed supplement. Industries, 農業, livestock farming, ETC. are all showing interest in the eco-friendly and sustainable properties of biochar.

How to Use Sugarcane Bagasse Charcoal Making Machine?

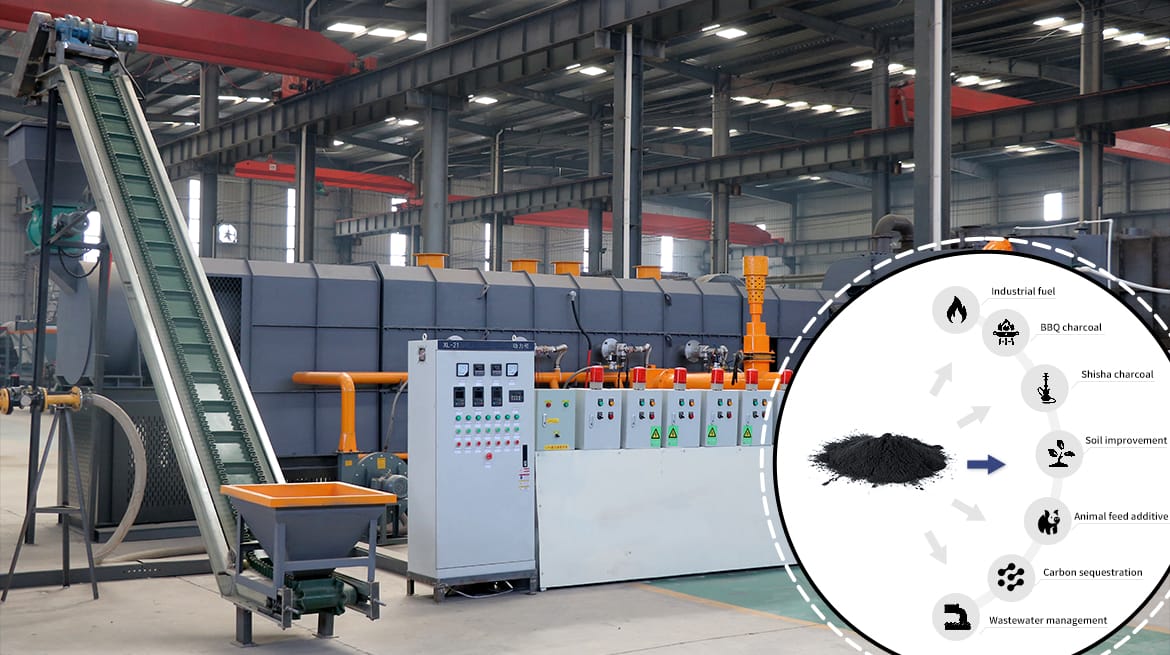

After acquiring the sugarcane charcoal making machine, you’re ready to commence the charcoal production process from the sugarcane bagasse. The sugarcane bagasse charcoal machine primarily operates on the principle of high-temperature carbonization. Here’s how it transforms sugarcane waste into charcoal:

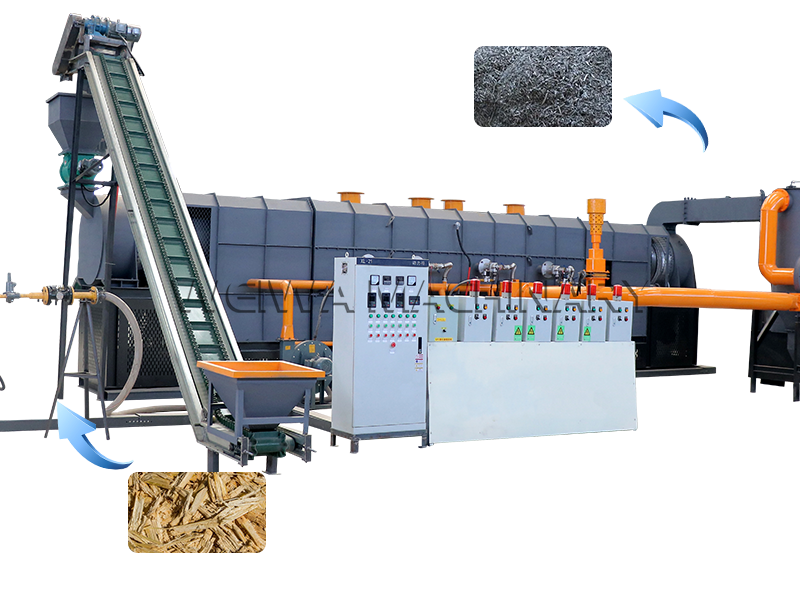

01 預處理

- 破碎 (選修的): The crushing system processes Sugarcane Bagasse into target sizes (小於20毫米).

- 烘乾 (選修的): The drying system processes the Sugarcane Bagasse to a moisture content of less than 15%.

02 碳化

- 餵養: The Sugarcane Bagasse is automatically fed into the furnace via a conveyor belt, 螺旋送料器或 Z 形皮帶.

- 碳化: 主爐加熱後, 氣溫逐漸升高. The initial temperature helps dry out some of the moisture in the Sugarcane Bagasse. 當溫度達到 250 攝氏度, 去甲基化開始. 開始產生可燃氣體. 在 280 攝氏度, 放熱反應開始. 碳氫化合物分子分裂成更小的碳分子和氫分子. 開始生產木炭. 隨著氣溫的升高 450 攝氏度, 芳香環化合物開始反應.

03 放電

- Sugarcane Charcoal : 通過三級水冷卸料器, Sugarcane Charcoal below 45 收集攝氏度.

- 焦油 & 木醋液系列 (選修的): 通過冷凝器, 焦油 (生物質油) 和木醋分離並單獨收集.

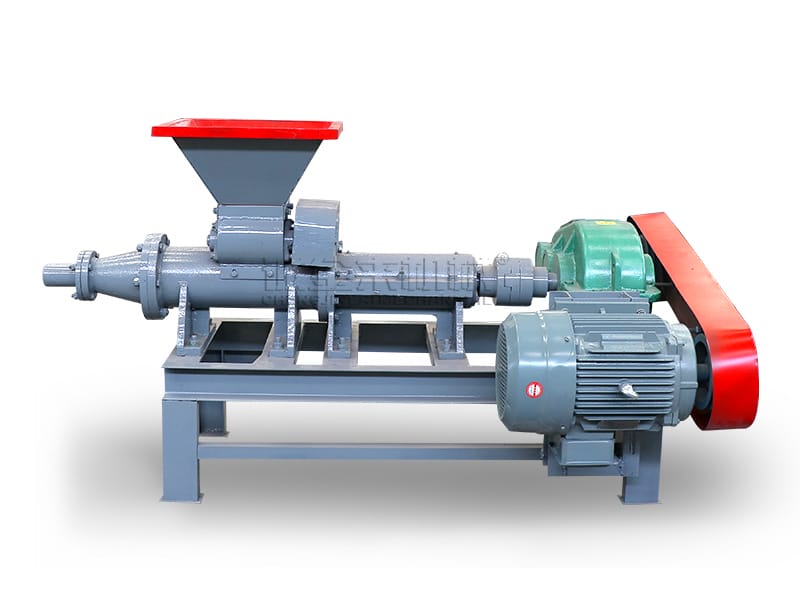

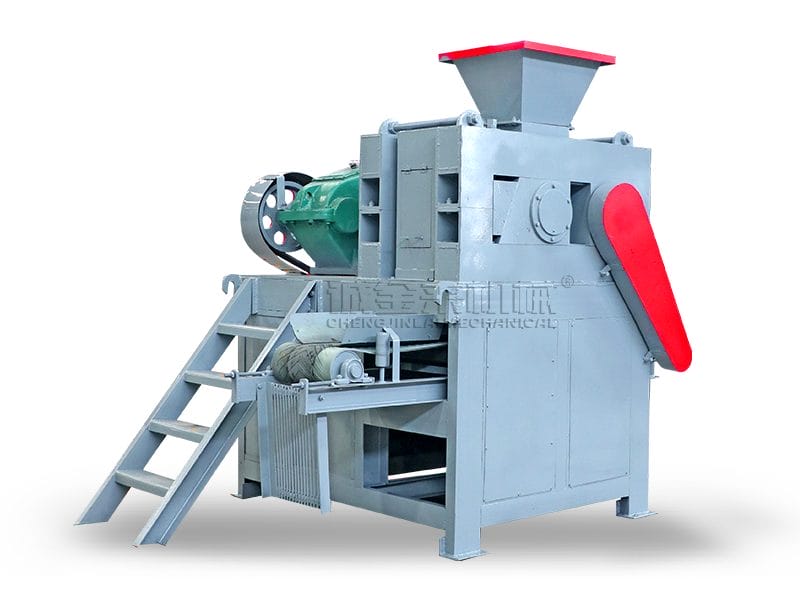

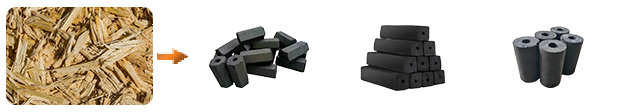

- Sugarcane Charcoal briquette making (選修的): After being processed by the Sugarcane Charcoal briquette machine, 木炭的原始形狀可以製成所需的形狀, 比如圓形的, 正方形, 戳, ETC.

04 可燃氣體回收

- 經過縮合脫硫處理後, 可燃氣體可回收再利用.

- 我們還可以將炭化爐的多餘熱量引入乾燥機,以回收可燃氣體, 從而節省烘乾機的燃料.

05 廢氣處理

- 排放氣體經噴淋塔處理, 水簾除塵塔, 和冷卻塔. 處理後排放氣體符合歐盟排放標準.

- 威瓦集團提供高標准定制廢氣處理系統.

Features of Sugarcane Charcoal Making Machine

配備報警裝置

PLC電櫃有報警裝置, 並且會有報警顯示和一些電氣故障報警.

帶防爆水封

可燃管道處設有防爆水封 (防止設備內可燃氣體壓力異常)

變頻風扇指南

所有管道中氣體的方向均由風機引導 (風扇是變頻的), 當管道堵塞時會在PLC上顯示.

熱效率高

物料不與煙氣接觸,不受熱空氣污染.

節能效果好

該設備熱利用率較高, 採用空氣換熱器可有效提高熱效率 5-10%, 且節能效果好.

How to Make Profit from Sugarcane Bagasse Charcoal Making Machine?

The produced sugarcane bagasse charcoal briquettes can bring good economic benefits because of their wide application across different industries. Investors can sell them to the relevant industries for profit.

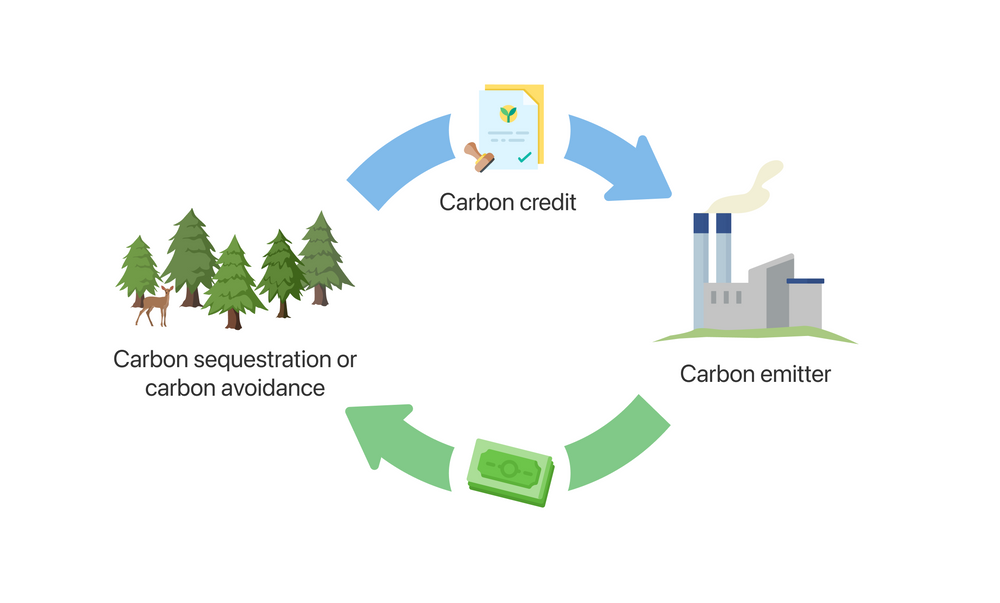

保證獲得碳信用額交易

- 含碳量高

- 100% 天然環保

- 捕獲大量二氧化碳並改善碳足跡

- 用於市場交易, 例如碳信用額, 碳補償

High-Quality Sugarcane Charcoal Output

By using Sugarcane Bagasse Charcoal Making Machine, 我們可以獲得最重要的最終產品, Sugarcane Bagasse Charcoal. 木炭可進一步加工成水煙或燒烤木炭, 兩者都具有很高的價值,可以應用於很多領域. 它是最適合水煙木炭或燒烤木炭生產的機器.

燒烤木炭

- 高碳熱量

- 低煙

- 灰分含量低

- 長時間燃燒的時間

- 果香木香

Hookah Charcoal /Shisha Charcoal

- 溫度穩定

- 高硬度

- 煙量低

- 長時間燃燒的時間

- 果香木香

土壤改良

- 80% 微孔結構改善土壤通氣和排水

- 提供一些微量元素, 比如鉀, 鎂, 鋅

- 鹼度和離子交換有助於調節土壤 pH 值並節省肥料成本

政策補貼申請

一些國家或地區對生物質能源的利用提供補貼或稅收優惠, such as the EU’s “Green New Deal” or China’s renewable energy support policy.

相關產品

The Sugarcane Bagasse Charcoal Making Machine can also process different raw materials

微信

微信

+8613838093177

+8613838093177