介紹

With global biomass energy market projected to reach $302 十億美元 2030 (彭博社), 將農業廢物轉化為木炭已經成為環境上的必不可少的,而且在經濟上可行. 在Weiwa機械, our engineered solutions – 包括high-output sawdust extrude machines, automated briquette presses, 和energy-efficient carbonization furnaces – transform waste into premium fuel with 40% higher calorific value than raw biomass.

The Growing Importance of Biomass Charcoal Machines

Biomass charcoal is an eco-friendly alternative to traditional fossil fuels. Made from agricultural waste like 稻殼, 木屑, 和木屑, it reduces deforestation and carbon emissions.

What Is a Sawdust Extrude Machine?

a木屑擠出機 compresses raw biomass (木屑, 稻殼, ETC。) into dense briquettes. By applying high pressure and heat, lignin in the material binds particles without additives. Our machines ensure high output with low energy consumption.

Key Features of Weiwa’s Sawdust Extrude Machine

- High-pressure compression for dense, 長燃煤球

- Low maintenance and energy-efficient operation

- Adjustable mold sizes for customized briquette shapes

木屑擠出機: Turning Waste into Valuable Fuel

木屑, a byproduct of wood processing, is often discarded. 然而, our 木屑擠出機 compresses it into compact briquettes, perfect for heating and industrial applications.

Benefits of Using Sawdust Charcoal

- Reduces agricultural waste pollution

- Produces clean-burning, smokeless fuel

- Cost-effective compared to traditional charcoal

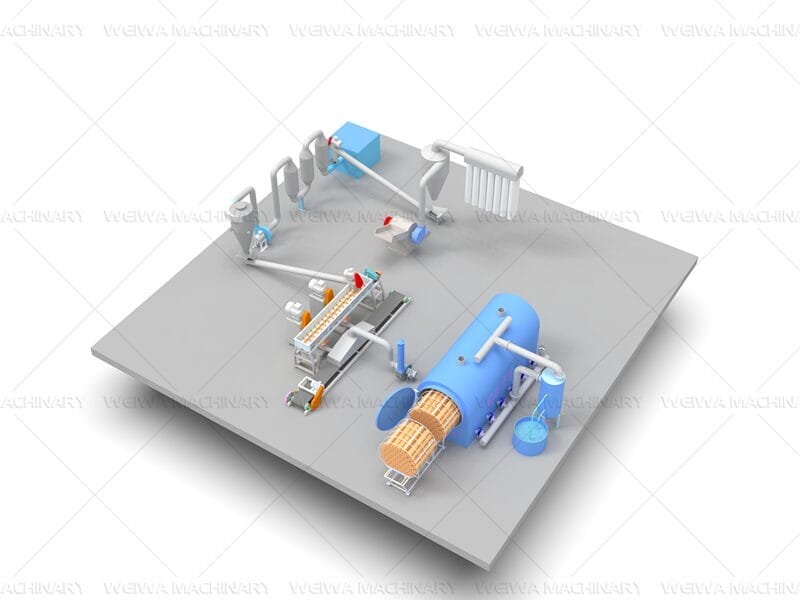

The Charcoal Production Line: From Raw Material to Finished Product

Weiwa Machinery offers a full charcoal product line, from raw material processing to final briquette packaging. Our integrated solutions include:

步 1: 破碎 & 烘乾

Biomass is crushed and dried to <20% moisture for optimal briquetting.

步 2: Briquetting with a Sawdust Extrude Machine

The 木屑擠出機 forms briquettes under high pressure

步 3: Carbonization in a Horizontal Carbonization Furnace

Briquettes are heated (500–800°C) in an oxygen-limited 臥式炭化爐, converting them into charcoal.

步 4: 包裝 & Storage

The final charcoal is cooled, 包裝好的, and stored for distribution.

Why Choose Weiwa Machinery for Your Charcoal Production Needs?

With 超過 30 多年行業經驗, Weiwa Machinery has established itself as a trusted leader in charcoal production technology. 我們的expert engineering team ensures every machine meets the highest standards of quality, 耐用性, and efficiency. Unlike generic suppliers, we provide full-service support, 包括on-site installation and commissioning, so your production line runs smoothly from day one.

We understand that every client has unique needs, which is why we offer fully customizable solutions—whether you need a compact briquetting system or a large-scale carbonization plant. Our machines are built for long-term performance with minimal maintenance, reducing downtime and maximizing productivity.

此外, we prioritize environmental compliance, ensuring our equipment meets international emissions and safety standards. From technical consultation to after-sales service, our dedicated team is committed to your success.

Choose Weiwa Machinery—where experience, innovation, and reliability come together to power your charcoal business.

關於Weiwa機械

WEIWA機械 is a leading manufacturer of biomass processing equipment, 包括sawdust extrude machines, 機器煤球, 和rice husk charcoal machines. 隨著超過 15 多年的專業知識, we provide turnkey solutions for sustainable fuel production.

Want to build a charcoal production line? Get a Free Customized Plan from Weiwa’s engineers today!

Tel/WhatsApp:+86 1838093177

電子郵件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177