工業木芯片木炭塊生產線是一種高級設備,可有效利用生物質廢物(例如木屑),稻殼,花生殼,木屑材料. 旨在將木屑轉換為高熱量木炭塊,以滿足對環保燃料的市場需求. 隨著可持續發展的概念變得越來越受歡迎, wood chip charcoal blocks are gradually gaining widespread attention due to their low pollution and high efficiency.

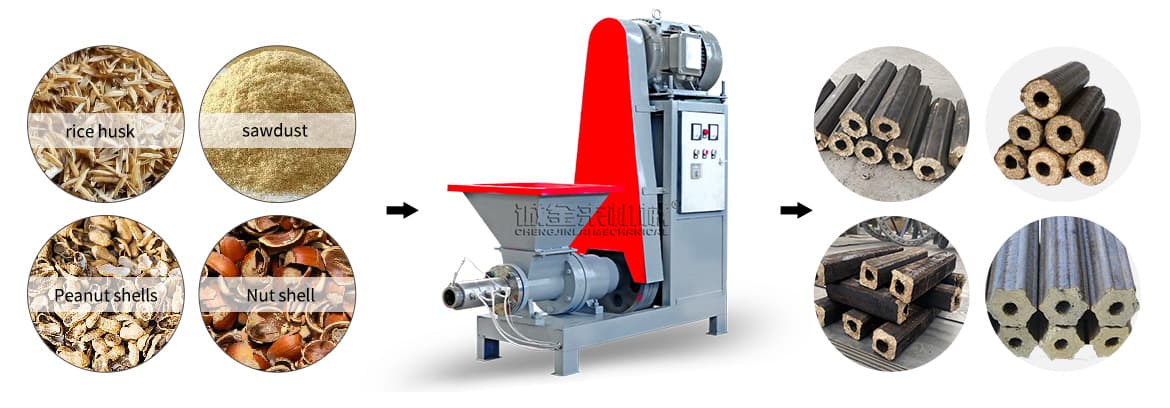

Charcoal Briquettes Making Machine Raw Materials & 最終產品

Charcoal briquette making machine has a wide range of raw materials,例如木材原木, 竹子, 椰子殼, 棕櫚貝殼, 木屑, 稻殼, 堅果殼, 核桃殼和各種生物質原材料.

Raw material is graphite powder, coal powder or mineral powder, it can be crushed directly and added into the appropriate binderand stirred evenly before moulding and making rods.

(尺寸:少於 5 毫米;Moisture content:少於 25%)

Final products:

◆該生物燃料成型棒直徑為45-80mm, 發生在空心四角形或六角形圓柱體或空心六角形且體上有15-20mm孔的空心六角形.

◆可用形狀: 正方形, 六角形, 五角大樓, 有邊的五邊形, 有邊六邊形.

◆可用直徑為: 50毫米,60毫米,70毫米,80毫米等等

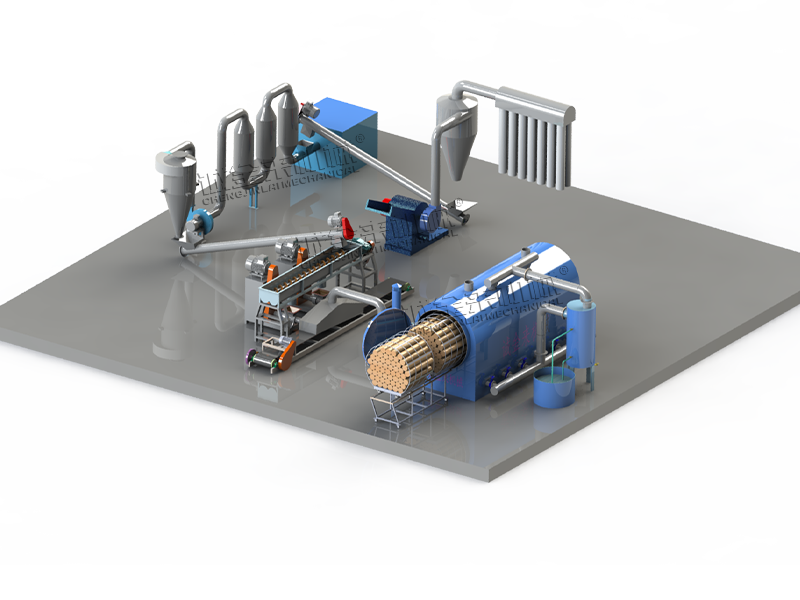

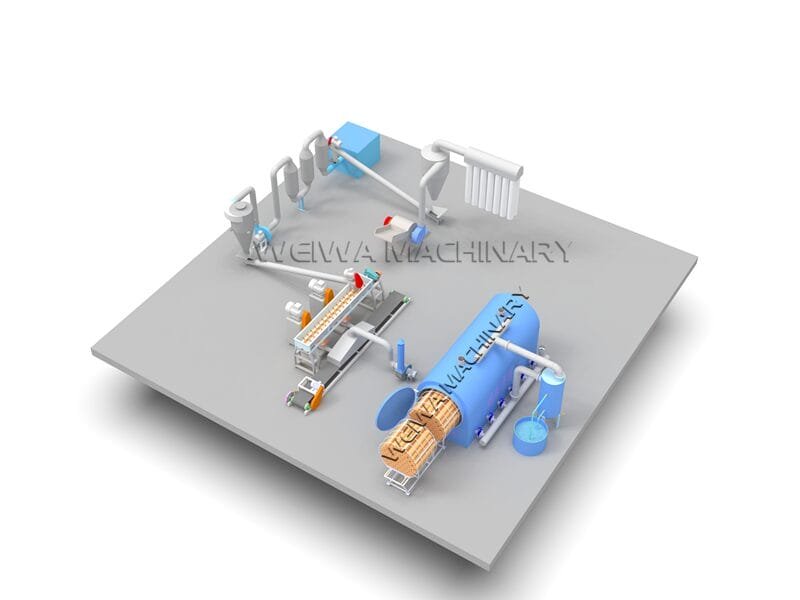

Wood Charcoal Briquette Production Line Process Flow

步 1. 粉碎機將原料粉碎成小塊 (直徑約3-5mm)

步 2. 烘乾機將原料烘乾至水分低於 12%

步 3. 將物料放入木炭機中,不添加任何化學物品,

步 4. 碳化木煤棒

步 5. 成品木炭可達45mm , 50毫米,60毫米 ,70毫米 ,80直徑毫米

A.Drum chipper is a special equipment for producing all kinds of high-quality wood chips. It can cut logs and small-diameter wood into high-quality wood chips with uniform size and flat cuts.

B.Double mouth crusher is a fine crushing equipment that can process all kinds of wood, 木材廢料, 分支, 分支, 木屑, 板裝飾, 吠, 竹子, 竹皮和其他原材料一次進入木屑.

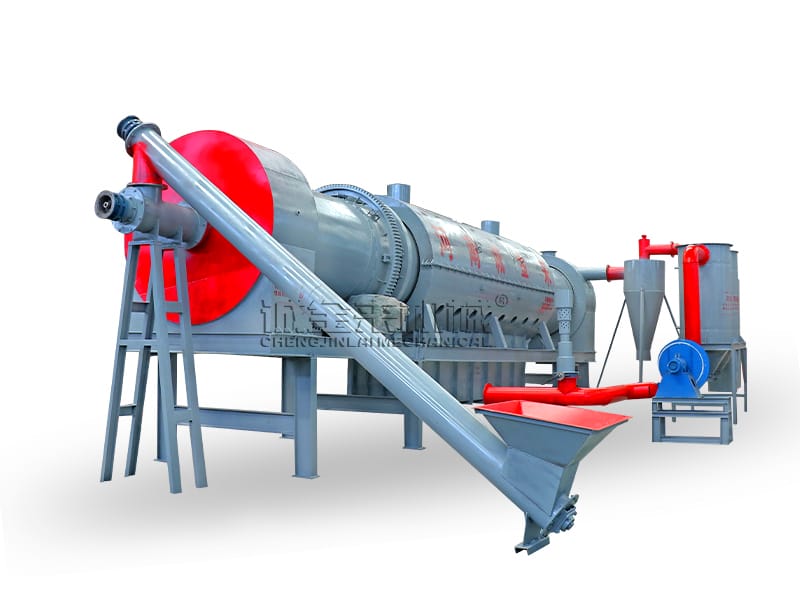

C.Rotary drum dryer is one of the traditional drying equipment, 這是可靠的, 操作靈活, 適應性強, 而且處理能力很大. 根據乾燥要求確定設備的直徑和長度.

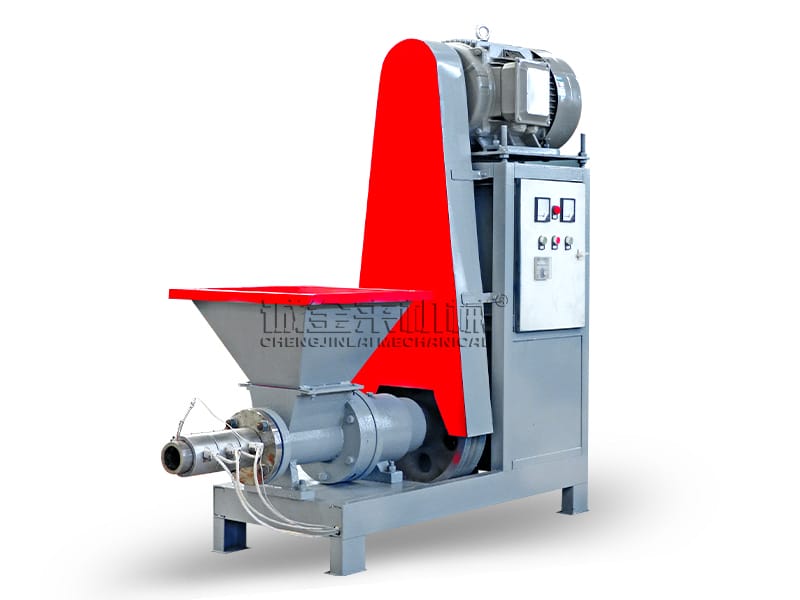

D.Wood charcoal briquette machine is a kind of forming equipment, 主要通過合格的鋸末和木質材料或生物質材料 (尺寸5mm以下, 12% 水分) 通過螺旋, 高壓成型缸和加熱環. The machine-made rod is formed under high temperature and high pressure.

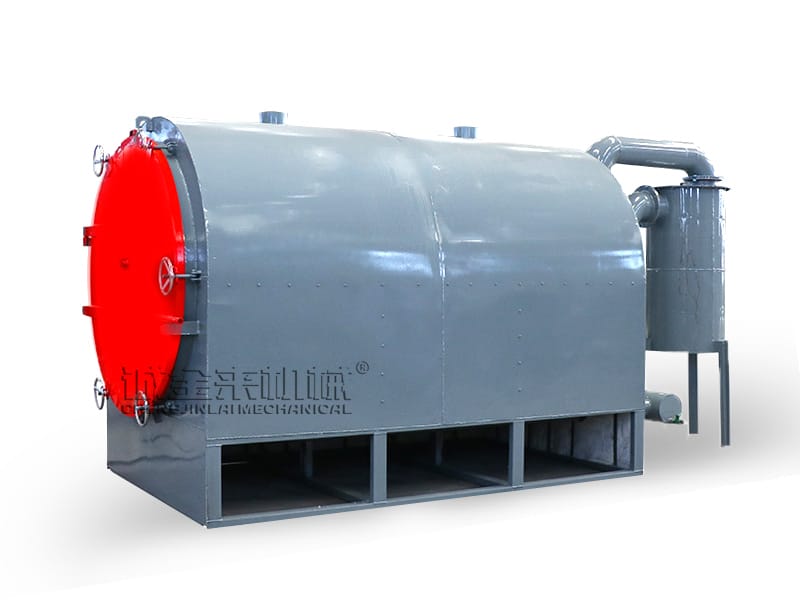

E.Hoisting carbonization furnace is an environmentally friendly and smokeless carbonization equipment. It can not only carbonize machine-made rods, but also directly carbonize raw materials such as logs, 木塊, 椰子殼, and tree bark.

We Provide 100% Free Charcoal Machine Production Line Design

當您打算配置碳化生產線時, 請讓我們知道您的詳細信息.

這些材料包括:

1.原材料類型, 尺寸, 水分

2.植物尺寸

3.變壓器容量

4.成品的類型和大小

5.對產出的需求

盡可能詳細, 最好的, 為了自定義自己的碳化生產線設備, 我們將免費為您提供3D站點計劃圖.

*不同的材料將被設計為不同的生產解決方案, 諮詢時客戶需要通知我們材料’ 水分, 粒度, 屈服, 煤球大小, 形狀, 某些特殊情況可能需要輔助設備,例如其他類型的破碎機,其他類型的混合器,屏幕網格, 振動篩, 粘合劑餵食器, 液體混合罐, 磁分離器, 電子帶稱重器, 可變頻率驅動器.

總之, the industrial wood chip charcoal block production line is an important environmental protection technology. It effectively converts wood chip resources into high-value fuel and helps achieve the goal of sustainable development. If you are interested in the equipment or have any questions, please leave a message and we will wholeheartedly provide you with professional answers and solutions!

相關文章

微信

微信

+8613838093177

+8613838093177