The Rising Demand for Sawdust Briquettes in Indonesia

印度尼西亞, with its vast forestry and agricultural sectors, generates massive amounts of sawdust waste daily. Instead of letting this biomass go to waste, turning it into sawdust briquettes or charcoal briquettes presents a lucrative opportunity.

在WEIWA機械, we specialize in designing and manufacturing high-efficiency sawdust briquette machine lines, including a 5-ton/hour carbonization production line tailored specifically for Indonesian clients. Our solutions are optimized for local raw materials, 能源效率, and high output, ensuring maximum profitability.

Why Indonesia is the Perfect Market for Sawdust Briquette Production?

Indonesia has a thriving biomass waste stream, particularly from:

- Wood processing industries (furniture, plywood, ETC。)

- 農業殘留物 (棕櫚內核殼, 椰子殼)

- Forestry operations (sawmills, logging residues)

The government is also promoting renewable energy和carbon-neutral solutions, making sawdust briquettes and charcoal briquettes highly sought after for:

Household heating & 烹飪 (cleaner alternative to firewood)

Industrial boilers & 熔爐 (cost-effective fuel)

Export markets (high demand in Japan, Korea, and Europe)

與我們的customized 5-ton/hour production line, Indonesian clients can efficiently convert waste into profitable briquettes.

The Process of Making Briquettes from Sawdust

1. 原料準備 (Sawdust Collection & 烘乾)

Before making briquettes from sawdust, the raw material must be:

- Cleaned (free from metal, stones, or impurities)

- Dried (moisture content should be 8-12% for optimal binding)

我們的sawdust briquette machine line for Indonesia includes drying systems to ensure the sawdust is at the right moisture level.

2. Briquetting (Extrusion into Dense Blocks)

The core of the process is sawdust extrusion using a 木屑壓球機 (也稱為briquette press).

How Does a Sawdust Extruder Work?

- The dried sawdust is fed into the machine.

- High pressure and heat (from friction) compress the sawdust into dense 煤炭球 (logs or pellets).

- No binder is needed (natural lignin in wood acts as a binding agent).

我們的Weiwa sawdust briquette machines are designed for high throughput (5T/H)和低能耗.

3. 碳化 (Turning Briquettes into Charcoal Briquettes)

To produce charcoal briquettes from sawdust, the briquettes must undergo 碳化 (a heating process in an oxygen-free environment).

Our Carbonization Furnace Options:

The result? High-quality charcoal briquettes with 長時間燃燒的時間, low smoke, and high calorific value—perfect for cooking and industrial use.

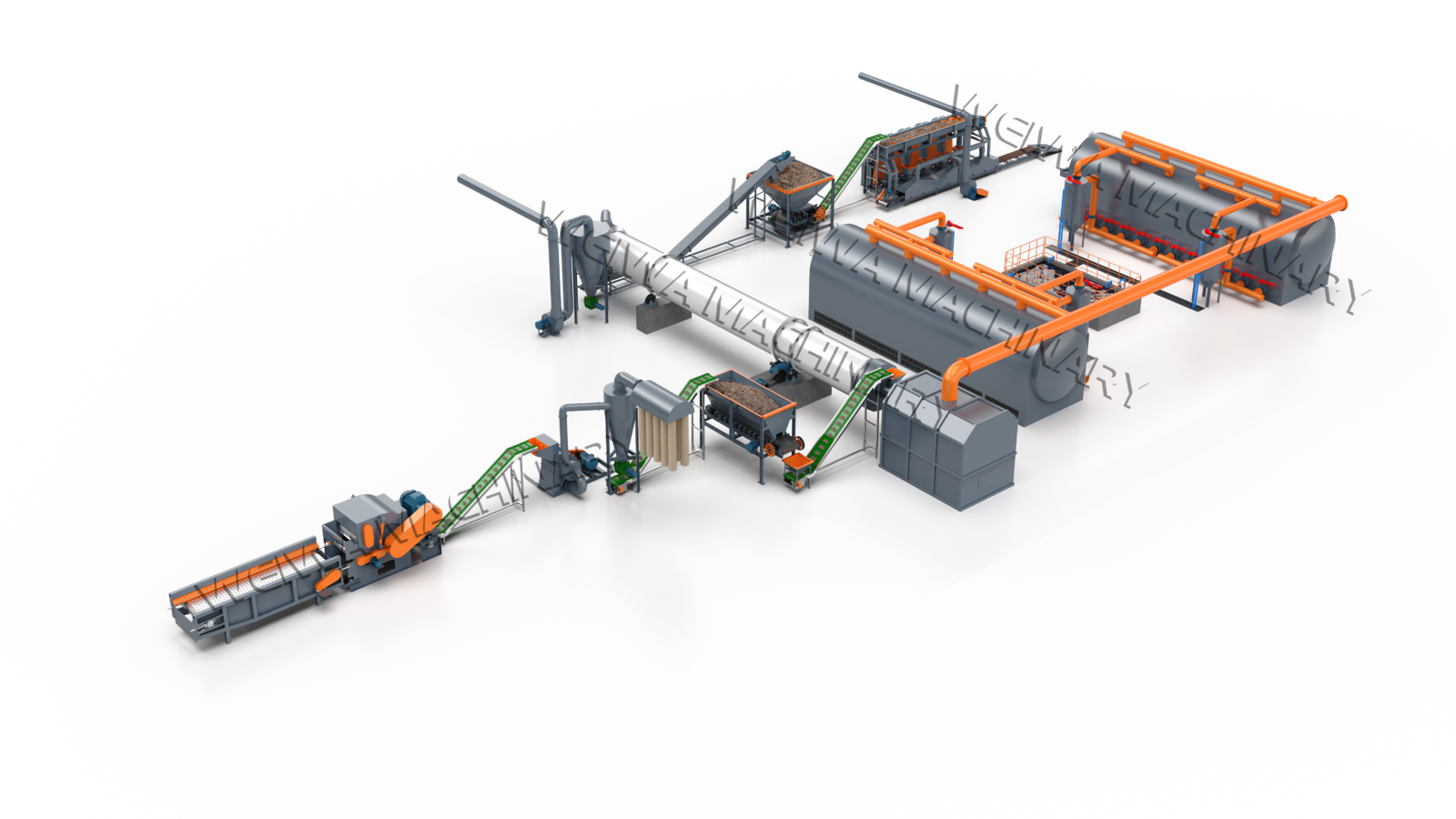

Customized 5-Ton/Hour Sawdust Briquette Machine Line for Indonesia

Based on our client’s field layout design, we engineered a fully automated 5T/H production line that includes:

1. Raw Material Feeding System

- Belt conveyors for smooth sawdust transport

- Vibrating screens to remove impurities

2. Drying System

- Rotary drum dryer (adjustable temperature for optimal moisture control)

3. Briquetting Machine (木屑擠出機)

- High-pressure screw press (produces dense, 統一的煤球)

- Cooling system to prevent deformation post-extrusion

4. 碳化爐

- Continuous carbonization for high efficiency

- Smoke filtration to meet environmental standards

5. 包裝 & Storage

- Automatic bagging machine (選修的)

- Warehousing space in the layout design

Our engineers customized the field layout to fit the client’s available space, ensuring smooth workflow and minimal manual labor.

The Future of Sawdust Briquette Production in Indonesia

The biomass energy market in Indonesia is growing rapidly, driven by:

Government incentives for renewable energy

Export opportunities for eco-friendly charcoal

Increasing demand for clean cooking fuels

與我們的5-ton/hour production line, Indonesian entrepreneurs can scale up production, reduce waste, and tap into a profitable market.

Why Choose Weiwa Machinery for Your Sawdust Briquette Line?

在WEIWA機械, we’ve been in the biomass equipment industry for over 30 years, specializing in:

Custom-designed sawdust briquette machine lines

Professional after-sales support & training

Field layout planning for maximum efficiency

我們的5-ton/hour carbonization line for Indonesia is a proven solution for turning sawdust into valuable briquettes and charcoal.

關於 WEIWA機械

With 30+ 多年的經驗, WEIWA機械 is a leading manufacturer of biomass briquette and charcoal equipment. We offer:

✔ Customized solutions (tailored to your raw materials & production needs)

✔ Professional after-sales service (安裝, training, maintenance)

✔ Design & layout planning (optimized for your factory space)

We serve clients globally, 包括印度尼西亞, 馬來西亞, 越南, and Africa.

Get in touch with us for a free quote or technical consultation!”

微信

微信

+8613838093177

+8613838093177