The Fully Automatic Charcoal Ball Briquette Production Line is a high-efficiency system designed to process charcoal or coal powder into uniform briquettes with minimal manual intervention. 木炭煤石生產線廣泛用於燒烤木炭等行業, 燃料生產, 冶金, and chemical processing.This charcoal briquette making machine uses advanced automation technology, and can achieve fully automated operation from raw material processing to finished product discharge.

Charcoal Briquette Production Line Features

✔ Efficient molding: fully automatic briquetting machine is used to ensure uniform molding, improve product density and flame resistance.

✔ Intelligent operation: automatic feeding, pressing and conveying, reducing manual intervention and improving production efficiency.

✔ Multi-specification adaptation: the mold can be adjusted to produce carbon balls of different sizes and shapes to meet diverse needs.

Charcoal Briquette Making Machine Advantages

✔ Industry-leading: intelligent automatic control, reducing labor costs by 30%;

✔ High-quality charcoal balls: high molding precision, long-lasting flame resistance, not easy to break;

✔ Multi-purpose compatibility: suitable for a variety of raw materials such as charcoal, 煤粉, mineral powder, ETC。;

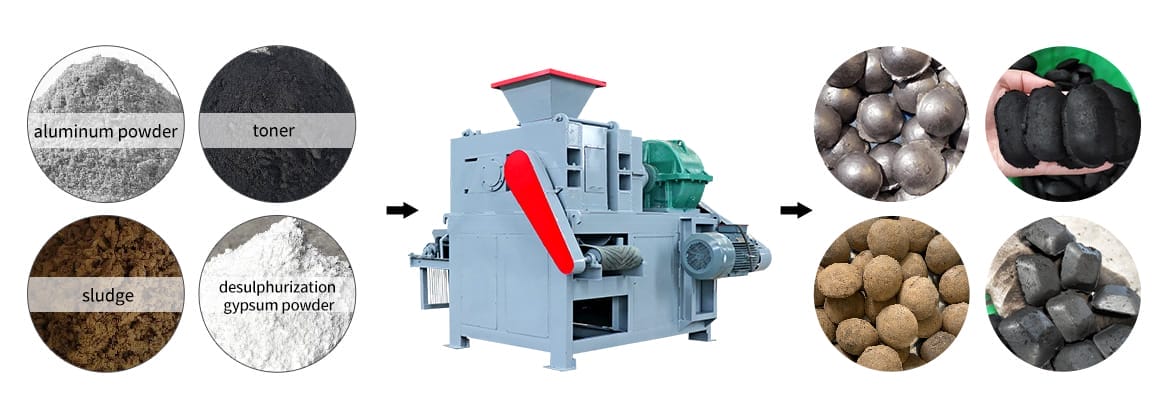

Charcoal Ball Briquette Making Machine Raw Material & Final Product

Charcoal ball briquette production line has a wide range of raw materials,例如木材原木, 竹子, 椰子殼, 棕櫚貝殼, 木屑, 稻殼, 堅果殼, walnut shells and various biomass raw materials.The charcoal briquette making machine is suitable for charcoal processing plants, coal product companies, and environmentally friendly fuel producers who need efficient and stable charcoal ball production equipment to increase production and reduce labor costs.

木炭適用的字段

The charcoal made by the charcoal briquette production line with long burning time, 高熱量價值, 沒有煙, 沒有爆炸, environmental protection and economy.Charcoal can be used for domestic combustion, 鍋爐, 燒烤, 壁爐加熱, 發電廠和其他方面.

此外, 由於其獨特的微孔結構和超吸附能力, 它被廣泛用於許多領域,例如食物, 藥店, 化工, 冶金, 國防, 農業和環境保護.

Charcoal Ball Briquette Production Line Process Flow

During the production process, the raw materials are first crushed and screened to ensure uniform particles of wood chips;

然後, they are mixed and conditioned with water to achieve optimal pressing conditions;

然後, the wood chips are formed into standard charcoal balls by a briquette press;

(During this process, the temperature and pressure can be precisely controlled according to demand to ensure the stability of the finished product quality)

最後, the finished charcoal balls are packaged through an automated conveying system and are ready for sale;

Charcoal Briquette Production Line Key Machine

A.Integrated Crusher is a large-scale wood crushing equipment for crushing branches, 樹根, templates, wooden pallets, waste furniture, nailed wood and other materials.

B.Rotary drum dryer is one of the traditional drying equipment, 這是可靠的, 操作靈活, 適應性強, 而且處理能力很大. 根據乾燥要求確定設備的直徑和長度.

C.Continuous carbonization furnace is a new type of carbon powder carbonization machine that feeds in raw materials and discharges finished carbon. It belongs to the external heating type drying and carbonization integrated machine.

D.Hammer mill is a fine crushing equipment that can process all kinds of wood, 木材廢料, 分支, 分支, 木屑, 板裝飾, 吠, 竹子, 竹皮和其他原材料一次進入木屑.

E.Wheel Mill Mixer是一種結合了根據最新外國車輪銑削和混合設備的優勢設計的車輪銑削和混合. 適用於混合粉末和顆粒狀材料, 例如碳粉, 煤粉, 黏土, 耐火泥, 尾巴, 礦渣, 型砂, ETC.

固定混合槍管由電動三角帶驅動,以驅動葉輪旋轉, 和水和粘合劑完全混合. 這是增加試劑反應時間並增強材料反應質量的必要裝置.

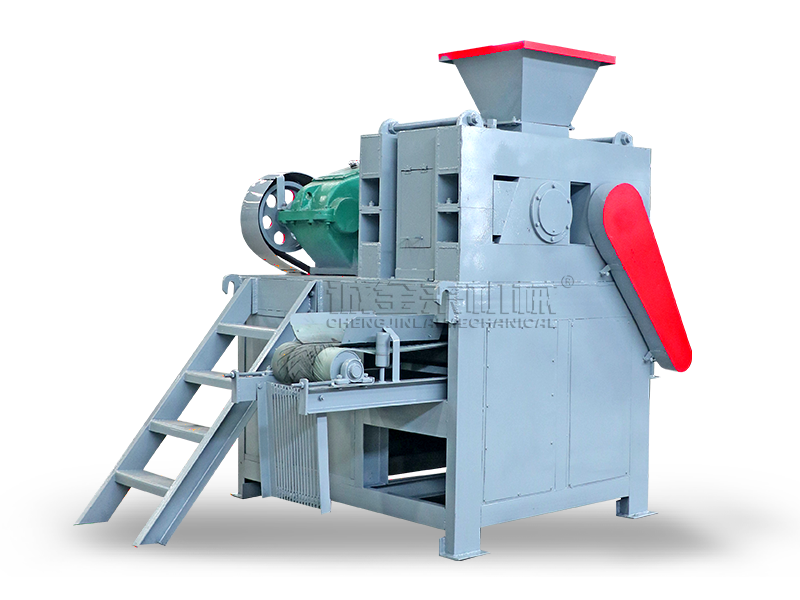

G.Charcoal ball briquette machine is a device that presses powdery and granular materials into molding. It can press various mineral powder, metal powder, 煤粉, 焦炭粉和其他成型材料.

H.Mesh belt dryer uses hot air as the drying medium, and the hot air is sent to the dryer through the induced draft fan to dry the materials; the processed materials are turned over in the dryer through a multi-layer cycle, and the hot air passes through from bottom to top The mesh belt and material layer are dried layer by layer to achieve the purpose of drying.

We Provide 100% Free Charcoal Briquette Production Line Design

When you plan to configure a charcoal ball briquette production line, 請讓我們知道您的詳細信息.

這些材料包括

1.原材料類型, 尺寸, 水分

2.植物尺寸

3.變壓器容量

4.成品的類型和大小

5.對產出的需求

盡可能詳細, 最好的, in order to customize your own charcoal briquette production line equipment, 我們將免費為您提供3D站點計劃圖.

不同的材料將被設計為不同的生產解決方案, 諮詢時客戶需要通知我們材料’ 水分, 粒度, 屈服, 煤球大小, 形狀, 某些特殊情況可能需要輔助設備,例如其他類型的破碎機,其他類型的混合器,屏幕網格, 振動篩, 粘合劑餵食器, 液體混合罐, 磁分離器, 電子帶稱重器, 可變頻率驅動器.

總之, the fully automatic charcoal ball press production line is an important innovation that has promoted the modernization of the charcoal industry. Its high efficiency and environmental protection have made it widely praised worldwide and become an important tool for promoting sustainable development. If you are also interested in this charcoal ball press production line, please feel free to leave us a message online for more detailed information!!

相關文章

微信

微信

+8613838093177

+8613838093177