最近幾年, 對高品質水管的需求 (水煙) 木炭一直在穩步上漲, 尤其是在加納等地區, 社交吸煙和好客文化蓬勃發展的地方. 作為值得信賴的生物質加工設備製造商, WEIWA機械 has been at the forefront of providing efficient, 耐用的, 根據加納及烏幹達和印尼等鄰近市場客戶的獨特需求量身定制經濟高效的解決方案.

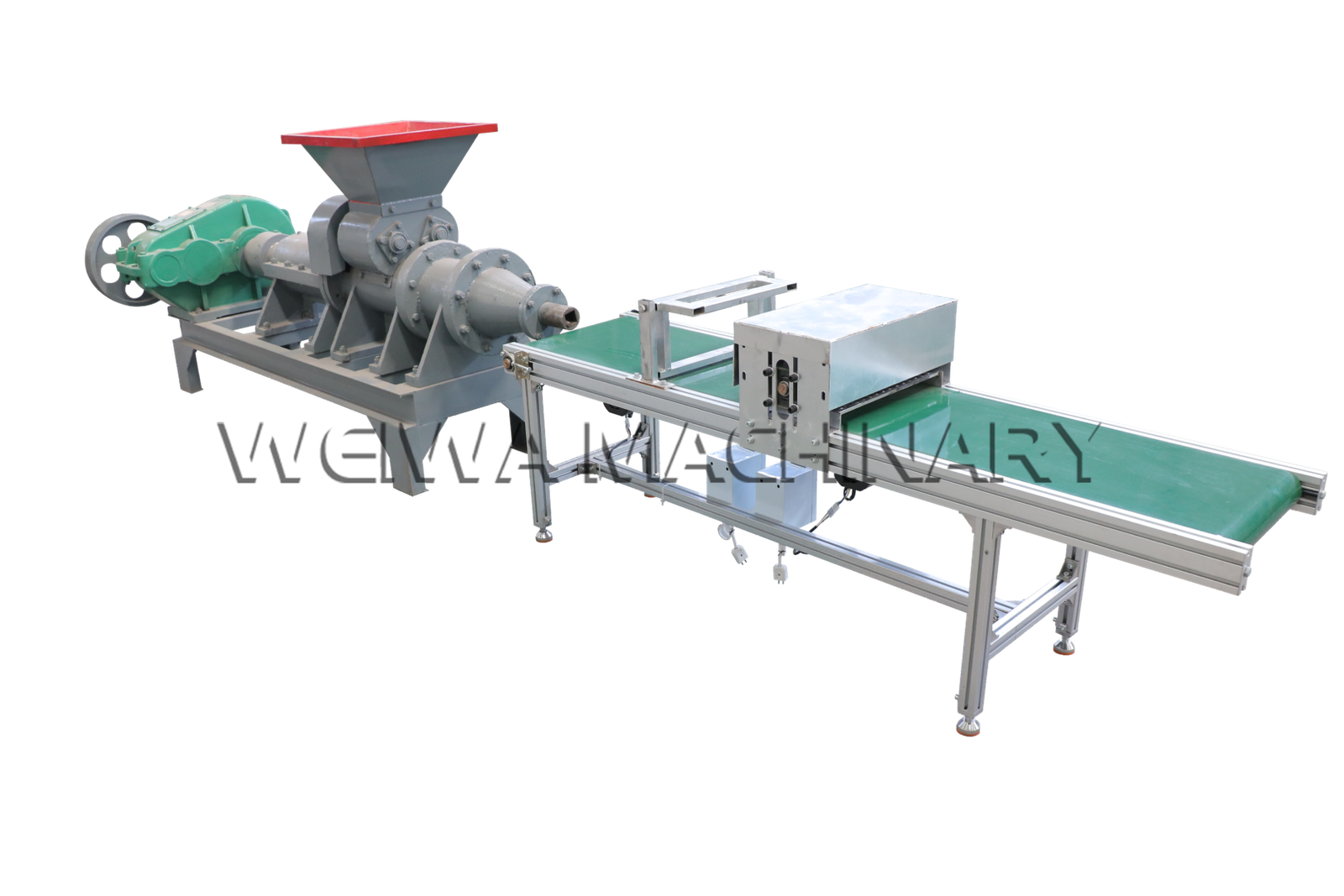

One of our flagship products — the charcoal extrude machine with cutter — has gained significant attention for its role in simplifying and optimizing the production of hookah charcoal.

The Rising Demand for Hookah Charcoal in Ghana

Hookah or shisha smoking has become a popular social activity across Africa, including Ghana. Unlike traditional charcoal briquettes, hookah charcoal requires specific characteristics: it must burn longer, produce minimal ash, emit little smoke, and most importantly, deliver a clean, consistent heat that doesn’t overpower the shisha flavors.

This has led to a growing market for high-quality water pipe charcoal, often made from natural materials like coconut shells, 木炭灰塵, or compressed biomass. To meet this demand locally, entrepreneurs in Ghana are turning to efficient production equipment — and that’s where our charcoal extrude machine for Ghana comes into play.

Introducing Weiwa’s Charcoal Extrude Machine with Cutter

在Weiwa機械, we’ve developed a specialized charcoal extrude machine with cutter that combines two essential functions in one seamless unit: extrusion and cutting. This machine takes powdered or granulated charcoal material, compresses it through a die to form long sticks or rods, and then automatically cuts them into uniform lengths — ideal for further carbonization into hookah charcoal.

Unlike traditional methods that involve manual shaping or separate cutting processes, our integrated system improves efficiency, reduces labor costs, and ensures a consistent product size — all critical factors for producing market-ready hookah charcoal.

How the Charcoal Extrude Machine Works

The process begins with preparing the raw material, which typically includes fine charcoal powder mixed with a natural binder such as starch or molasses. This mixture is fed into the hopper of our 木炭擠壓機, where it is compressed by a rotating screw mechanism.

As the material moves through the barrel, it is compacted and forced through a specially designed die. The shape and diameter of the extruded rods can be customized based on client preferences — a flexibility we offer to meet the exact needs of our Ghanaian customers.

Once the long rods exit the die, they are immediately cut into uniform lengths by the integrated cutter. This ensures that every piece is the same size, which is essential for even carbonization and a professional final product.

Why the Cutter Component Is Essential

Many clients initially consider purchasing a basic 木炭擠壓機 without a cutter. 然而, adding the cutter offers several advantages:

- Time Efficiency: Manual cutting is labor-intensive and inconsistent. Our cutter automates this step, dramatically speeding up production.

- Consistent Product Size: Uniform lengths ensure even burning and a better end-user experience for hookah smokers.

- Labor Savings: Reduces the need for additional manpower, allowing small producers to scale up with minimal overhead.

- Improved Safety: Automated cutting minimizes the risk of injuries associated with manual cutting tools.

For clients in Ghana looking to establish a professional and efficient production line, 的charcoal extrude machine with cutter is clearly the superior choice.

Customizing the Machine for the Ghana Market

Understanding the unique needs of our Ghanaian clientele, Weiwa Machinery has tailored our charcoal extrude machine for Ghana to handle local raw materials, power supply conditions, and operational preferences. Our machines are designed to be:

- Durable: Built with high-quality steel to withstand continuous operation in tropical conditions.

- Easy to Operate: Featuring intuitive controls and minimal maintenance requirements.

- Energy Efficient: Optimized to run on standard local power supplies without compromising performance.

- Affordable: We offer competitive charcoal extrude machine price options without sacrificing quality or durability.

We also provide pre-installation guidance, training for operators, and ongoing after-sales support to ensure our clients get the most out of their investment.

The Science Behind Hookah Charcoal Production

Producing high-quality hookah charcoal involves more than just shaping the material. The extrusion process plays a crucial role in determining the charcoal’s density, burn time, and heat consistency — all of which are vital for a great hookah experience.

When charcoal dust is compressed through our extruder, the pressure creates a dense, uniform structure. This density ensures slower combustion, which translates to longer burn times. The extrusion process also aligns the particles in a way that promotes even heat distribution, reducing the formation of hot spots that can ruin the shisha flavor.

After extrusion and cutting, the rods are typically carbonized in a kiln or drum. This final step removes volatile compounds, leaving behind a clean-burning charcoal that’s perfect for hookah use. Our clients in Ghana often follow up with a natural coating or polishing step to enhance appearance and performance.

Benefits of Using Weiwa’s Charcoal Extrude Machine in Ghana

Entrepreneurs in Ghana who invest in our charcoal extrude machine with cutter enjoy several benefits:

- High Production Output: Our machines are capable of producing hundreds of sticks per hour, 取決於模型.

- Cost-Effective Production: By automating key steps, our machines help reduce labor and material waste.

- Scalability: Whether you’re a small startup or looking to expand an existing operation, our machines can grow with your business.

- Local Support: We understand the Ghanaian market and offer tailored advice, training, and support.

Understanding the Charcoal Extrude Machine Price

One of the most common questions we receive from potential clients in Ghana is about the charcoal extrude machine price. 在Weiwa機械, we strive to offer the best value by balancing cost, 品質, and performance.

Our pricing is competitive, especially when you consider the durability, 效率, and after-sales service we provide. We also offer different models to suit various production scales and budgets. Whether you’re just starting out or looking to upgrade an existing setup, we have a solution that fits your needs.

We believe that investing in a Weiwa charcoal extrude machine for Ghana is not just a purchase — it’s a step toward building a sustainable and profitable business in the growing hookah charcoal market.

Why Ghanaian Entrepreneurs Choose Weiwa Machinery

Over the years, we’ve built strong relationships with clients in Ghana, Uganda, 印度尼西亞, 及以後. Our success is built on:

- Client-Centric Approach: We listen to our clients’ needs and offer tailored solutions.

- Quality Assurance: Every machine is rigorously tested before it leaves our factory.

- Technical Support: Our team is always available to assist with installation, training, and troubleshooting.

- 全球範圍, Local Focus: While we serve clients worldwide, we understand the specific challenges and opportunities in markets like Ghana.

結論: Partner with Weiwa for Your Hookah Charcoal Production

If you’re in Ghana and looking to enter or expand in the hookah charcoal market, Weiwa Machinery’s charcoal extrude machine with cutter offers the perfect combination of efficiency, 品質, and affordability. Our machines are designed to help you produce consistent, high-quality water pipe charcoal that meets the demands of local and export markets.

With a focus on durability, ease of use, and customized solutions, Weiwa Machinery is your trusted partner in biomass processing equipment. Let us help you turn raw materials into a profitable business venture.

關於 WEIWA機械

Weiwa Machinery is a leading manufacturer of biomass processing equipment, specializing in charcoal making machines, extruders, and related machinery for global markets. With years of experience and a commitment to quality and innovation, we provide tailored solutions to clients in over 50 國家, including Ghana, Uganda, 印度尼西亞, 及以後. Our mission is to empower entrepreneurs with reliable, 高效的, and affordable machinery to build successful businesses in the renewable energy and biomass sectors. Contact us today to learn more about our products and how we can support your production goals.

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 電子郵件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177