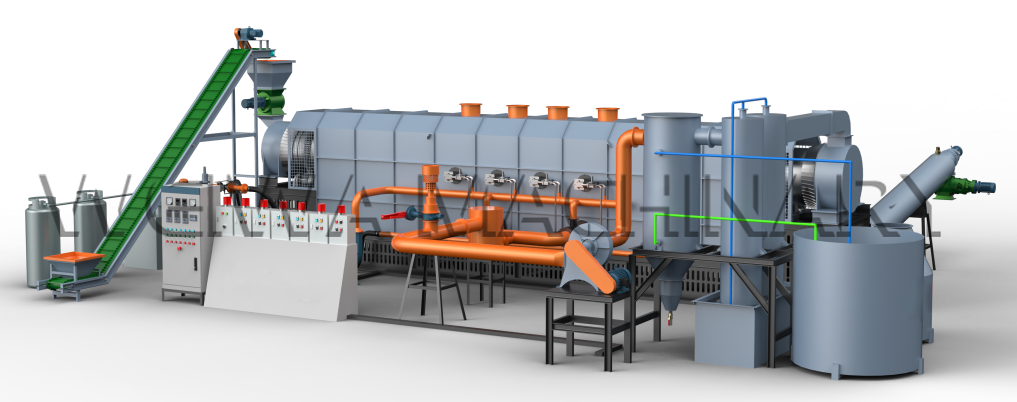

最近幾年, 全球對可持續木炭和生物碳產品的需求激增, 尤其是在印度等新興市場. 隨著各行業尋求更清潔的, 更有效率, 以及環保的木炭生產方式, 連續碳化爐 have emerged as a game-changing solution. 在Henan Weiwa機械製造公司, 有限公司, 總部位於鞏義市, 河南省, China, we’ve been at the forefront of designing and manufacturing advanced 木炭製造機, including our highly efficient 連續式炭化爐.

最近, we had the opportunity to test our continuous carbonization furnace for Hawaiian walnut shell on behalf of an esteemed client from India. This trial not only demonstrated the versatility and efficiency of our equipment but also highlighted the growing potential of the continuous carbonization furnace in India.

What Is a 連續碳化爐?

Before diving into the test results, 讓我們澄清一下什麼是連續式炭化爐 actually is and why it’s become such an important piece of equipment in the biomass carbonization industry.

Defining Continuous Carbonization

碳化 is the process of converting organic materials—such as wood, 椰子殼, 稻殼, or in this case, Hawaiian walnut shells—into charcoal through the application of heat in an oxygen-limited environment. Traditional methods often involve batch processing, which can be time-consuming and inefficient.

a連續式炭化爐, by contrast, allows for a non-stop, 24/7 手術. Raw materials are fed into the furnace continuously, carbonized, and the resulting charcoal is discharged without needing to stop the machine. This leads to higher productivity, lower energy consumption, and more stable operation—making it ideal for commercial-scale charcoal production.

Why It Matters for Global Markets?

As countries like India push for greener energy alternatives and sustainable waste management, technologies like the 連續式炭化爐 offer a practical solution. They enable the conversion of agricultural residues, forestry waste, and even unconventional materials like Hawaiian walnut shells轉化為有價值的木炭, used in everything from cooking fuel to industrial applications.

The Hawaiian Walnut Shell Is An Unconventional Yet Promising Biomass

Our recent test focused on using Hawaiian walnut shells as the raw material—a somewhat unique choice that sparked interest among our Indian clients. While most carbonization projects use more common materials like sawdust, 椰子殼, or rice husks, Hawaiian walnut shells present different physical and chemical properties, including higher density and varying moisture content.

Why Hawaiian Walnut Shells?

The decision to test with Hawaiian walnut shells came from our Indian client, who has access to a steady supply of these shells as a byproduct of local food processing or imports. The goal was to determine whether our 連續式炭化爐 could effectively process this material into high-quality charcoal, opening up new possibilities for waste valorization and cost-efficient raw material sourcing.

Our team was curious to see how the furnace would handle the density and combustion behavior of the walnut shells, especially in a continuous feeding environment.

Conducting the Continuous Carbonization Furnace Test

在Weiwa機械, every piece of equipment we produce undergoes rigorous testing before being delivered to clients. For this particular project, we set up a controlled environment in our factory to simulate real-world operating conditions for our Indian customer.

設定

We used our standard model of the 連續式炭化爐, configured to handle small to medium batches for trial purposes. The Hawaiian walnut shells were pre-processed to ensure consistent size and moisture levels, then fed into the furnace using our automated feeding system.

Key parameters such as temperature, retention time, and airflow were closely monitored throughout the carbonization cycle. Our engineers tracked the carbonization rate, charcoal yield, and overall energy efficiency to evaluate the performance.

Observations During the Test

One of the first things we noticed was how well the 連續式炭化爐 handled the Hawaiian walnut shells. Despite their slightly denser structure compared to other biomass materials, the furnace maintained a stable internal temperature, ensuring uniform carbonization.

The charcoal produced was of high quality—dense, with a shiny black appearance and a high fixed carbon content. Our client was particularly impressed with the low ash content and the pleasant aroma, indicating a clean burn and high-quality end product.

Another highlight was the continuous operation aspect. Unlike batch furnaces that require frequent stopping and restarting, our continuous model ran smoothly for hours, demonstrating its suitability for large-scale, uninterrupted production.

Why the 連續碳化爐 Is Ideal for the Indian Market?

India presents a unique and promising landscape for the adoption of 連續式炭化爐 technology. With a growing population, increasing energy demands, and a strong focus on sustainability, the country is actively seeking innovative solutions for waste management and renewable energy production.

Agricultural and Forestry Waste Abundance

India generates massive amounts of agricultural residues each year, including rice husks, 甘蔗甘蔗渣, 椰子殼, 還有更多. 此外, regions with nut processing industries—like those that might use Hawaiian walnut shells or similar materials—could benefit greatly from turning these byproducts into valuable charcoal.

我們的連續式炭化爐 is designed to handle a wide variety of biomass materials, making it an incredibly versatile solution for India’s diverse waste streams.

Environmental and Economic Benefits

The ability to convert waste into usable charcoal not only reduces environmental pollution but also creates new economic opportunities. Farmers, processors, and small enterprises can turn what was once considered waste into a profitable product.

Moreover, 的連續式炭化爐 is energy-efficient and environmentally friendly, producing minimal smoke and emissions when combined with auxiliary equipment like a smoke purification system. This aligns perfectly with India’s environmental regulations and sustainability goals.

Market Demand for High-Quality Charcoal

There is a growing demand for high-quality charcoal in India, not just for domestic cooking but also for industrial applications such as metallurgy, activated carbon production, and water filtration. 我們的連續式炭化爐 enables the production of consistent, high-grade charcoal that meets these needs.

The Future of Continuous Carbonization Furnace in India

Based on the success of this test and the increasing interest from Indian clients, we believe the 連續式炭化爐 has a bright future in the Indian market.

Emerging Opportunities

- Rural Entrepreneurship: Small-scale entrepreneurs in rural areas can use our 木炭製造機 to start local charcoal production businesses, creating jobs and boosting the local economy.

- Industrial Applications: Industries looking for reliable sources of activated carbon or specialty charcoal will find our equipment capable of meeting their exacting standards.

- Waste Management Solutions: Municipalities and private companies can leverage our technology to manage agricultural and forestry waste more effectively, turning it into a valuable resource.

Our Commitment to Indian Clients

在Weiwa機械, we are committed to providing tailored solutions that meet the specific needs of our Indian clients. Whether it’s adapting our 連續式炭化爐 to handle unique materials like Hawaiian walnut shells or offering localized support and training, we strive to ensure that our clients succeed.

A Successful Test with Global Implications

The trial of our 連續式炭化爐 using Hawaiian walnut shells for an Indian client was more than just a technical demonstration—it was a glimpse into the future of sustainable charcoal production. The furnace performed exceptionally well, producing high-quality charcoal efficiently and continuously, even with an unconventional raw material.

This test underscores the versatility and reliability of our 木炭製造機 and highlights the growing potential of continuous carbonization furnace technology in markets like India. As more businesses and entrepreneurs look for innovative ways to convert waste into wealth, we are confident that our equipment will play a key role in shaping a cleaner, greener future.

關於 WEIWA機械

Henan Weiwa機械製造公司, Ltd. has over 30 多年的經驗 in the machinery manufacturing industry. Located in Gongyi City, 河南省, China, we specialize in the production, r&D, and sales of a wide range of equipment, 包括機器煤球, carbonization furnaces, 和木炭製造機.

At WEIWA MACHINERY, our mission is to ”為客戶創造價值”. We are market-oriented and dedicated to meeting and serving our clients’ needs with high-quality machinery, professional support, and innovative solutions. Whether you’re looking to produce charcoal from biomass, upgrade your production line, or explore new raw materials like Hawaiian walnut shells, Weiwa Machinery is your trusted partner in carbonization technology.

Contact us today to learn more about our continuous carbonization furnace and how it can benefit your business.

微信

微信

+8613838093177

+8613838093177