介紹: Why Nigerian Customers Trust Weiwa’s Charcoal Making Machines

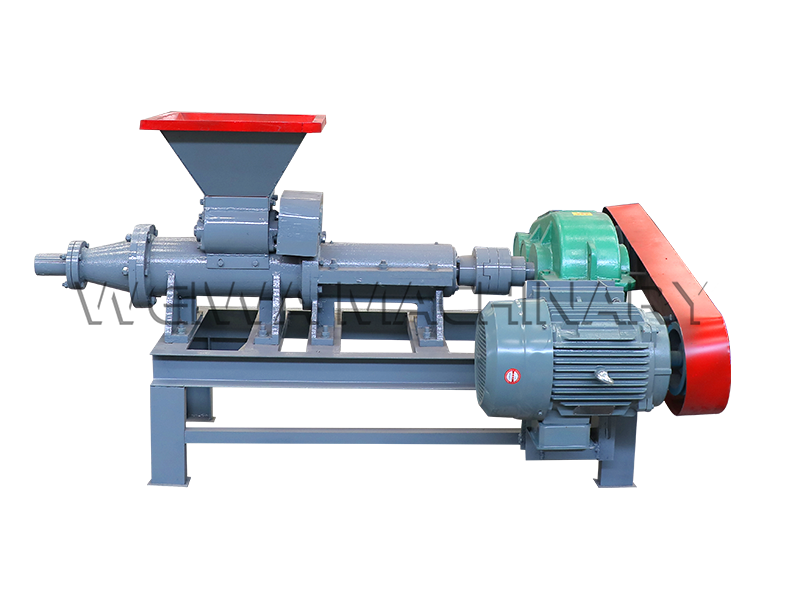

Nigeria, with its growing demand for BBQ fuel and industrial charcoal, has seen a surge in interest in charcoal extrude machines和rod briquette making machines. 在WEIWA機械, we recently hosted a Nigerian client who visited our factory to inspect and test our 木炭擠壓機 (棒式壓球機).

The Growing Demand for Charcoal Briquettes in Nigeria

Nigeria faces challenges with traditional charcoal production (從木頭), 砍伐森林, 以及不斷上漲的燃料成本. 因此, compressed charcoal briquettes (尤其是棒狀的) are gaining popularity—they burn longer, 是環保的 (由農業廢棄物製成), 並且具有成本效益.

This is where our 木炭擠壓機 (也稱為棒型煤球機) comes in—transforming charcoal powder into dense, high-quality rods for BBQs, households, and industries.

Why Nigerian Customers Choose Weiwa’s Charcoal Extrude Machine

1. 高效率 & Low Energy Consumption

我們的木炭製造機 (棒式壓球機) is designed to produce consistent, high-density charcoal rods with minimal energy waste. During the Nigerian client’s visit, they were impressed by:

- Stable extrusion pressure ensuring uniform briquette shape.

- Low electricity consumption compared to traditional methods.

- Adjustable mold sizes for different rod diameters (common in Nigeria: 20毫米, 25毫米, 30毫米).

2. Raw Material Flexibility

Unlike some machines that require highly processed charcoal powder, our rod briquette machine in Nigeria works well with:

- Fine charcoal dust (from coconut shells, 木頭, 或生物質).

- Agricultural waste blends (for cost-effective fuel production).

The Nigerian client tested with locally sourced charcoal powder and confirmed excellent binding without excessive binder needs.

3. Easy Operation & Low Maintenance

Many Nigerian buyers worry about machine complexity. 然而, our 木炭擠壓機 features:

- Simple hydraulic or mechanical operation (easy for local technicians).

- Minimal wear parts (reducing long-term maintenance costs).

- Quick setup & training (our engineers guided the Nigerian team during the visit).

Factory Visit & Live Machine Testing: What the Nigerian Client Experienced

步 1: Machine Inspection & Build Quality Verification

The Nigerian client arrived at our factory and inspected the rod briquette machine firsthand. Key observations included:

- Heavy-duty steel construction (ensuring durability in high-volume production).

- Smooth extrusion mechanism (no jamming or uneven pressure).

- Safety features (emergency stop, protective covers).

步 2: Live Testing with Real Charcoal Powder

The most exciting part was the live test run. Using locally available charcoal powder, we:

https://youtu.be/5cLgc3VPxb0

- Fed the raw material into the hopper (ensuring proper flow).

- Adjusted the extrusion pressure based on desired rod hardness.

- Produced continuous, well-formed charcoal rods (without cracking or breaking).

The Nigerian client was impressed by the consistency and density of the briquettes, stating:

“We expected some trial runs, but your machine worked perfectly from the first batch!”

步 3: Performance Discussion & Customization Options

After testing, we discussed:

- Production capacity (how many rods per hour based on their needs).

- Binder options (whether they needed additional binding agents).

- After-sales support & training (ensuring smooth operation in Nigeria).

Why This Machine is Perfect for the Nigerian Market

1. Solving Local Challenges

- Deforestation reduction (promoting sustainable charcoal production).

- Affordable fuel alternative (for households and restaurants).

- Export potential (high-quality briquettes for regional markets).

2. 性價比高 & Profitable

- Low production cost (using waste materials).

- High demand (BBQs, hotels, and households in Nigeria buy briquettes daily).

3. Trusted by Nigerian Buyers

Our previous Nigerian clients have successfully set up 生產線 using our 木炭擠壓機, confirming its reliability.

結論: Ready to Start Your Charcoal Briquette Business in Nigeria?

If you’re a Nigerian entrepreneur looking for a 可靠的, high-performance charcoal extrude machine or rod briquette press, Weiwa Machinery is your trusted partner. 我們的factory-tested machines, local client success stories, and hands-on support make us the best choice for charcoal production in Nigeria.

Contact us today for a quote, machine demo, or export details to Nigeria.

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 電子郵件:info@cjlmachinegroup.com

關於 WEIWA機械

WEIWA機械 is a leading manufacturer of 木炭製造機, briquette presses, and biomass equipment with years of experience serving global clients, including Nigeria. We specialize in:

High-quality rod briquette machines (for charcoal & 生物量).

Customizable solutions (based on your raw materials & production needs).

Reliable after-sales support (training, spare parts, and technical guidance).

Our mission is to help businesses worldwide produce eco-friendly fuel efficiently and profitably.

Visit our factory or request a live demo—let’s build your success together.

微信

微信

+8613838093177

+8613838093177