Введение

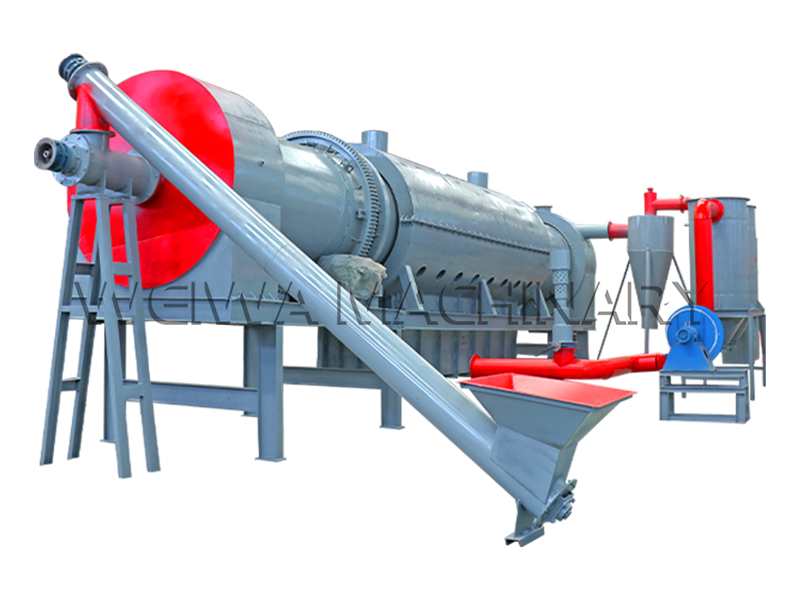

Indonesia’s agricultural sector produces vast quantities of organic waste, в том числеMacadamia nut shells, который представляет неиспользованный ресурс для устойчивой энергии и повышения почвы. ВWeiwa Machinery, we have pioneered advanced печь непрерывного карбонизации technology that efficiently converts these agricultural byproducts into high-quality biochar—a valuable product with applications in agriculture, energy, and environmental remediation.

This comprehensive guide explores:

- The science behind continuous carbonization technology

- Why Macadamia nut shells are an ideal feedstock

- Real-world performance data from Indonesian operations

- The economic and environmental benefits of our system

- Why global clients choose Weiwa Machinery

We extend an open invitation to Indonesian enterprises to visit our production facility and witness firsthand how our technology can revolutionize biomass processing in your region.

Section 1: Understanding Continuous Carbonization Technology

1.1 The Science of Carbonization

Carbonization is a thermochemical process that converts organic materials into carbon-rich solids (биоуголь) through pyrolysis—heating biomass in an oxygen-limited environment. Traditional batch carbonizers suffer from:

- Inconsistent temperature control

- High labor requirements

- Significant heat loss between batches

Нашпечь непрерывного карбонизации overcomes these limitations through:

- Automated feeding and discharge systems

- Precise temperature regulation (400-600°С)

- Integrated heat recovery technology

1.2 How Our Continuous System Works

The process occurs in four optimized stages:

Этап 1: Pre-Drying Zone

- Incoming biomass is gently heated to remove surface moisture

- Prepares material for efficient pyrolysis

Этап 2: Primary Pyrolysis Chamber

- Operating at 450-550°C, this is where true carbonization occurs

- Volatile compounds are driven off while carbon matrix remains

Этап 3: Secondary Combustion Zone

- Combustible gases are burned to maintain process heat

- Creates self-sustaining energy loop

Этап 4: Cooling and Collection

- Biochar is rapidly cooled to preserve quality

- Automated sorting removes any unprocessed material

Section 2: Why Macadamia Nut Shells Are the Ideal Feedstock

2.1 Unique Properties of Macadamia Shells

Our research shows Macadamia nut shells offer distinct advantages:

Physical Characteristics

- Exceptionally hard structure (Janka hardness ~3,500 lbf)

- Низкое содержание влаги (<15% in properly stored shells)

- High density (1.2-1.4 G/CM³)

Chemical Composition

- Fixed carbon content: 35-45%

- Volatile matter: 50-55%

- Ash content: <2%

2.2 Performance Advantages in Carbonization

When processed in our continuous furnace:

- Higher yield: 30-35% conversion to biochar vs. 20-25% for wood

- Superior product quality: Fixed carbon >85%

- Lower energy requirements: 15-20% less fuel needed

Section 3: Real-World Performance in Indonesia

3.1 Case Study: East Java Pilot Project

We conducted a 90-day operational trial with an Indonesian agricultural cooperative processing 8 tons/day of Macadamia shells:

Key Metrics

| Parameter | Result |

|---|---|

| Operational uptime | 98.7% |

| Biochar production rate | 2.8 tons/day |

| Energy consumption | 85 kWh/ton |

| Labor requirements | 1 operator/shift |

3.2 Product Quality Analysis

Independent lab testing confirmed:

- рН: 8.2-8.5 (ideal for acidic tropical soils)

- Surface area: 280-320 m²/g

- Cation exchange capacity: 45-50 cmol/kg

Section 4: Economic and Environmental Benefits

4.1 Financial Advantages

Our clients typically achieve:

- Payback period: 6-8 months

- ROI: 65-80% in first three years

- Value-added opportunities:

- Premium biochar sales ($450-600/ton)

- Carbon credit potential

4.2 Sustainability Impact

Each system provides:

- CO2 reduction: ~12 tons/day vs. open burning

- Waste utilization: 100% of feedstock converted

- Soil regeneration: Biochar improves water retention and nutrient availability

Section 5: Why Global Clients Choose Weiwa Machinery

5.1 Our Technological Edge

- Patented multi-zone heating system for uniform carbonization

- AI-powered process optimization continuously improves efficiency

- Modular design allows capacity expansion

5.2 Comprehensive Support Package

We provide:

- On-site installation and commissioning

- Operator training programs

- Remote monitoring support

- Annual maintenance contracts

Заключение: Your Invitation to Sustainable Innovation

The combination of Indonesia’s abundant Macadamia nut resources and Weiwa’s continuous carbonization technology creates unprecedented opportunities for:

- Agricultural cooperatives

- Renewable energy producers

- Environmental remediation projects

We invite you to:

- Schedule a factory tour to see our technology in action

- Submit your biomass samples for free processing trials

- Consult with our engineers about custom solutions

Contact our Indonesia representative today at [contact info] to begin your biochar production journey.

Тел./WhatsApp:+86 13838093177

Электронная почта:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177