Введение

In today’s eco-conscious world, businesses and industries are constantly seeking sustainable ways to manage waste and optimize fuel production. The hydraulic briquette press stands out as a revolutionary machine that transforms biomass waste into high-density, energy-efficient briquettes. Whether you’re in the recycling, agriculture, or energy sector, investing in a hydraulic briquette press can significantly boost productivity and profitability.

What Is a Hydraulic Briquette Press?

А hydraulic briquette press is an advanced briquetting machine that uses high-pressure hydraulic systems to compress raw materials (такие как опилки, agricultural waste, порошок древесного угля, or metal chips) into compact, однородные брикеты. Unlike mechanical presses, hydraulic models offer superior pressure control, ensuring higher density and better combustion efficiency.

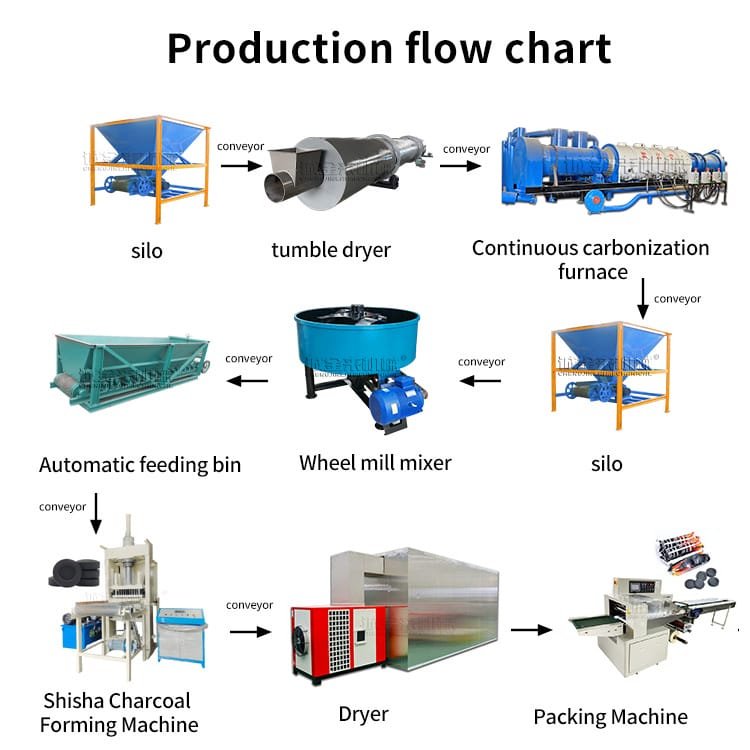

How Does It Work?

-

Material Feeding – Raw biomass is fed into the machine’s hopper.

-

Compression – A hydraulic cylinder applies extreme pressure (до 3000 psi or more), compacting the material.

-

Briquette Ejection – The formed briquettes are extruded in consistent shapes (цилиндрический, гексагональный, or custom molds).

-

Охлаждение & Упаковка – The briquettes cool and harden before being packaged for storage or sale.

Why Choose a Hydraulic Briquette Press Over Other Machines?

| Особенность | Hydraulic Press | Screw Press | Mechanical Press |

|---|---|---|---|

| Pressure Control | High & adjustable | Limited | Moderate |

| Briquette Density | Extremely high | Medium | Medium |

| Energy Efficiency | Optimized | High consumption | Moderate |

| Обслуживание | Low | High (screw wear) | Moderate |

| Noise Level | Low | High | Moderate |

Ключевые преимущества:

Higher Briquette Density – Longer burning time, better fuel efficiency.

Lower Operating Costs – Hydraulic systems consume less power than screw presses.

Versatile Material Use – Works with sawdust, рисовая шелуха, уголь, metal scraps, и многое другое.

Долговечность & Низкие эксплуатационные расходы – Fewer moving parts reduce wear and tear.

Экологически чистый – Converts waste into valuable fuel, reducing landfill use.

Who Can Benefit from a Hydraulic Briquette Press?

1. Уголь & Biomass Producers

Turn sawdust, Кокосовые ракушки, or wood chips into premium charcoal briquettes for grilling, обогрев, and industrial use.

2. Agriculture & Лесное хозяйство

Repurpose crop waste (рисовая шелуха, солома, Багасс) into sellable fuel briquettes.

3. Metal Recycling Plants

Compact metal shavings (aluminum, железо) for easier transport and smelting.

4. Waste Management Companies

Reduce landfill waste by converting organic residues into profitable briquettes.

5. Industrial Boiler Plants

Use high-density briquettes as a cost-effective alternative to coal or firewood.

Maximizing ROI with a Hydraulic Briquette Press

Investing in a high-quality hydraulic briquette press can yield quick returns through:

-

Selling briquettes to local markets, restaurants, or industries.

-

Reducing waste disposal costs by repurposing biomass.

-

Lowering energy expenses by using self-produced briquettes for heating.

Pro Tip: Pair your press with a карбонизация печи to produce high-value charcoal briquettes!

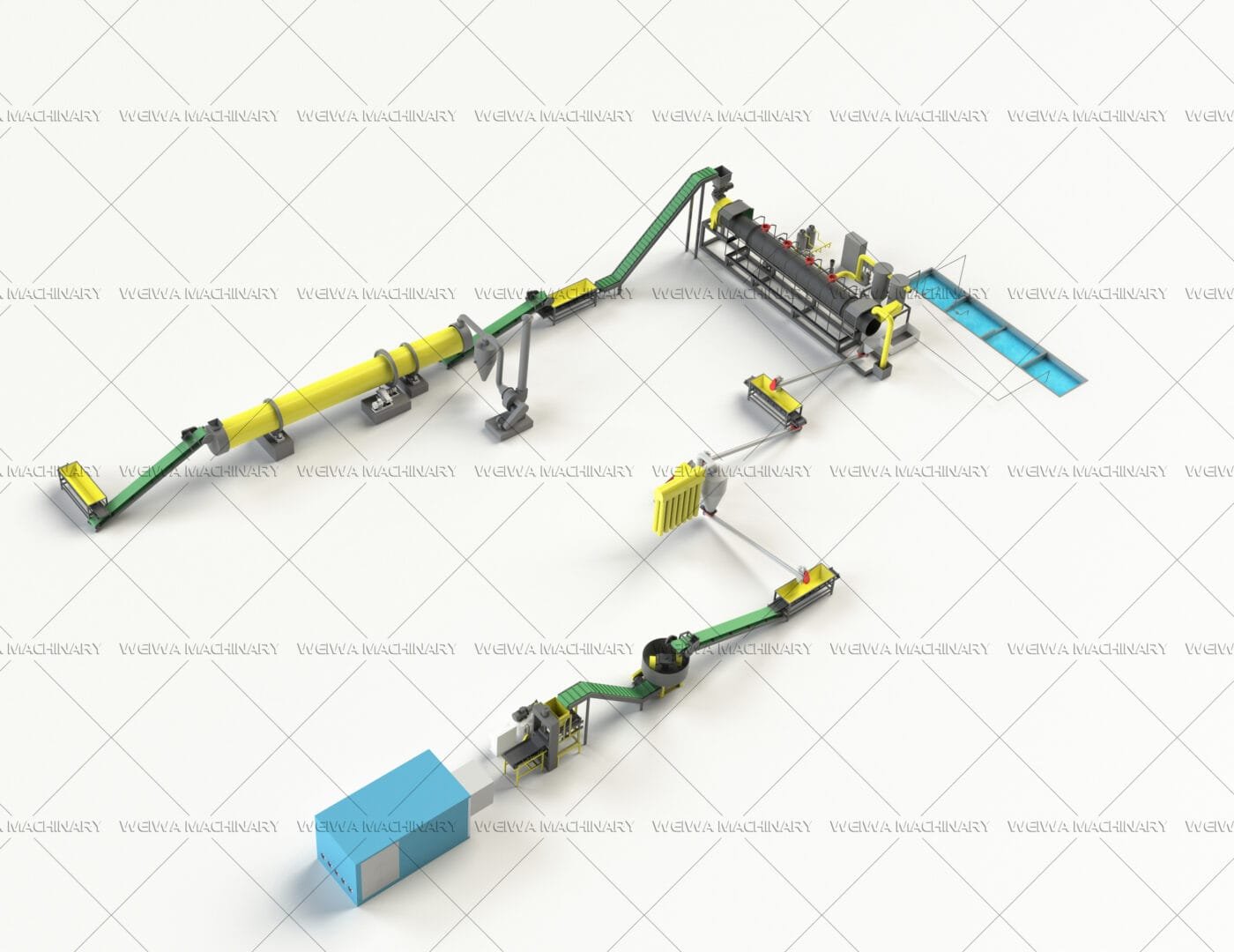

Our engineers can also design the drawings and plan the site for you based on your requirements and the site conditions.

Заключение: Is a Hydraulic Briquette Press Right for You?

If you’re looking for an эффективный, low-maintenance, and profitable way to process biomass or metal waste, a hydraulic briquette press is the ideal solution. With superior compression technology and long-term cost savings, it’s a smart investment for sustainable businesses.

Ready to boost your production? Contact us today to find the perfect briquette press for your needs!

Связаться с нами

Call Now: +8613838093177

Email Us: info@cjlmachinegroup.com

Want a FREE consultation? Let our experts help you choose the best machine for maximum efficiency!

WeChat

WeChat

+8613838093177

+8613838093177