Введение: The Evolution of Continuous Carbonization Technology

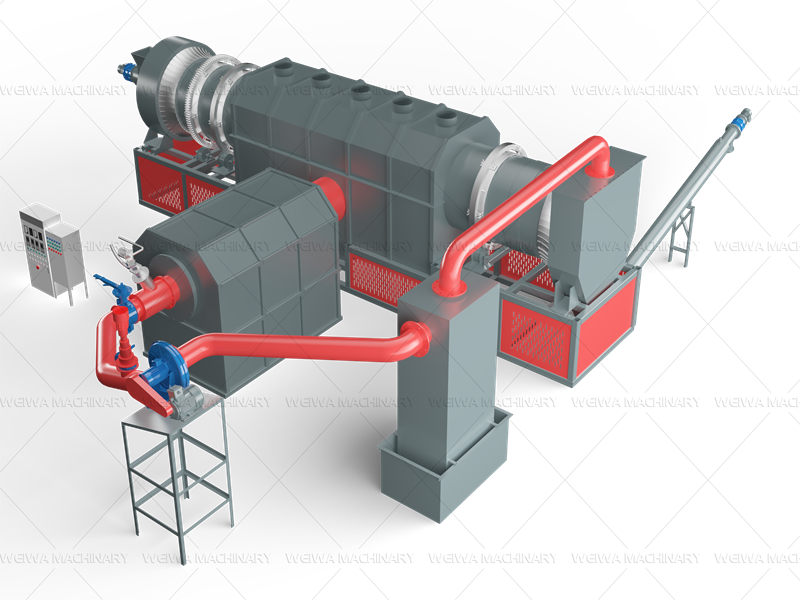

In the ever-evolving world of biochar and charcoal production, эффективность, energy recovery, and environmental compliance are no longer optional—they are essential. ВWeiwa Machinery, we’ve spent over 30 years refining our carbonization solutions, and our new continuous carbonization furnace with a secondary combustion chamber represents the next leap forward..

Why Continuous Carbonization Furnaces Are the Industry Standard

The Advantages of Continuous Carbonization Over Batch Processing

Traditional batch carbonization furnaces require frequent shutdowns for loading and unloading, leading to inefficient energy use and slower production. In contrast, печи непрерывного карбонизации like ours allow for non-stop operation, ensuring steady output and maximized productivity.

Нашпечь непрерывного карбонизации is designed for:

- High throughput (ideal for large-scale operations)

- Stable temperature control (ensuring consistent carbonization quality)

- Minimal manual intervention (reducing labor costs)

But what truly sets our latest model apart is the integrated secondary combustion chamber—a game-changer for energy efficiency and emission control.

Secondary Combustion Chamber Change the Continuous Carbonization Furnace

How the Secondary Combustion Chamber Works

Аsecondary combustion chamber (SCC) is the heart of our upgraded continuous carbonization furnace. Here’s how it works:

- Waste Heat Recovery – The primary carbonization process generates high-temperature flue gases rich in unburned volatile compounds. Instead of letting this heat escape, our SCC captures and re-burns these gases at 800–1200°C, ensuring complete combustion.

- Energy Recycling – The recovered heat is fed back into the carbonization furnace, reducing external fuel consumption (such as gas or coal) by up to 30-50%.

- Emission Purification – The SCC burns off harmful pollutants (like CO, метан, and particulate matter), ensuring the final exhaust meets strict environmental standards.

This means lower operating costs, reduced carbon footprint, and compliance with global emission regulations.

Why the Secondary Combustion Chamber Extends Furnace Lifespan

Direct exposure to high-temperature flames is one of the biggest wear-and-tear factors in traditional carbonization furnaces. НашSCC acts as a buffer, preventing direct flame contact with the main furnace and significantly extending its durability.

Кроме того, by pre-cleaning the exhaust gases, SCC reduces corrosion and fouling inside the furnace, leading to:

- Fewer maintenance shutdowns

- Longer equipment lifespan

- Lower repair costs

How to Operate the Continuous Carbonization Furnace with Secondary Combustion Chamber

ВWeiwa Machinery, we don’t just sell equipment—we ensure it works flawlessly for your specific needs. That’s why we offer comprehensive on-site testing and trial operation services for our continuous carbonization furnace with secondary combustion chamber, giving you 100% confidence before purchase.

Why Trial Runs Matter for Carbonization Equipment

Carbonization is a high-stakes process—temperature control, feedstock compatibility, and emission management must be perfectly optimized. Our trial program lets you:

- Validate real-world performance of the secondary combustion chamber’s heat recovery and emission purification under your specific conditions.

- Test different biomass feedstocks (деревянные чипсы, Кокосовые ракушки, рисовая шелуха, и т. д.) to see how the furnace adapts to your raw materials.

- Measure energy savings firsthand by monitoring fuel consumption reductions (typically 30–50% with our SCC).

- Observe emission compliance with local regulations, ensuring zero surprises during installation.

How Our Trial Process Works

Экологические преимущества: Cleaner Emissions & Carbon Credits

Meeting & Exceeding Emission Standards

Governments and industries worldwide are tightening carbon emission regulations. Нашsecondary combustion chamber ensures that:

- Сопутствующий (carbon monoxide) levels are minimized

- Particulate matter (PM2.5/PM10) is drastically reduced

- Volatile organic compounds (VOCs) are burned off efficiently

This makes our печь непрерывного карбонизации compliant with EU, НАС, and Asian environmental standards, helping clients avoid fines and gain regulatory approval.

Earning Carbon Credits & Improving Sustainability

By reducing emissions and improving energy efficiency, our furnace helps producers qualify for carbon credits under programs like:

- UNFCCC (Kyoto Protocol & Paris Agreement)

- REDD+ (Reducing Emissions from Deforestation & Forest Degradation)

- Voluntary Carbon Markets

This translates to additional revenue streams for biochar and charcoal manufacturers who prioritize green production.

Why Choose Weiwa Machinery?

Снад 30 years of expertise in карбонизация, биоуголь, and charcoal machinery, Weiwa Machinery is a trusted name in sustainable industrial solutions.

What We Offer:

Customized Design & Planning – We tailor each печь непрерывного карбонизации to your production needs, в том числеsite layout and workflow optimization.

Professional After-Sales Support – Our dedicated technical team provides installation guidance, troubleshooting, and maintenance training.

Proven Reliability – Our furnaces are tested in real-world conditions, ensuring durable performance and high yield.

Whether you’re a small-scale biochar producer or a large charcoal manufacturer, Weiwa Machinery has the right solution for you.

The Future of Carbonization is Here

Аnew continuous carbonization furnace with a secondary combustion chamber from Weiwa Machinery isn’t just an upgrade—it’s a revolution. By recycling waste heat, purifying emissions, and extending equipment life, it delivers:

✔ Lower operational costs

✔ Higher production efficiency

✔ Better environmental compliance

✔ Access to carbon credit opportunities

If you’re ready to upgrade your carbonization process, contact Weiwa Machinery today for a free consultation, custom design, or factory tour.

О машине Вейва

С30+ многолетний опыт in manufacturing печи карбонизации, biochar machines, and charcoal production equipment, Weiwa Machinery is a global leader in sustainable industrial solutions. Нашprofessional after-sales team, customized designs, and reliable performance make us the preferred choice for clients worldwide.

Contact us today for a quote or technical consultation!

- Моб:+8613838093177

- WhatsApp:+8613838093177

- Электронная почта:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177