介绍

At Weiwa Machinery, 我们专门研究高级木炭生产解决方案, 和我们的连续碳化炉 is revolutionizing how industries utilize agricultural waste like 稻壳. We warmly welcome Indonesian clients to visit our factory and observe firsthand how this technology transforms rice husk into high-quality 生物炭—a sustainable resource for agriculture, 活力, 还有更多.

该博客将探讨连续碳化背后的科学, 与传统方法相比的优势, 以及我们最近试验的令人印象深刻的结果.

什么是 连续碳化炉?

The Science Behind Continuous Carbonization

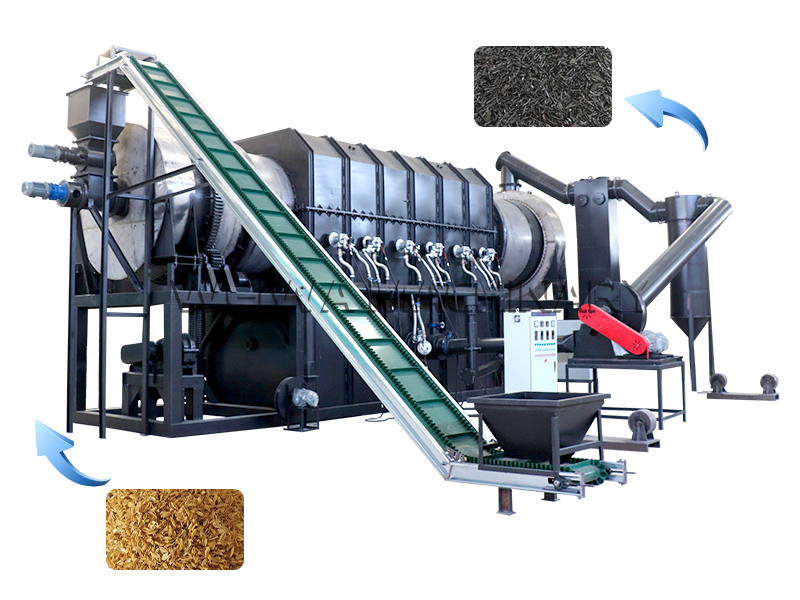

a连续碳化炉 is an automated system designed to convert biomass (例如。, 稻壳, 椰子壳, 木屑) 通过热解转化为木炭——在氧气有限的环境中进行热分解过程. 与间歇式炉不同, our continuous system operates non-stop, ensuring higher efficiency, 降低能源消耗, 和一致的输出.

Key Components of Weiwa’s Continuous Carbonization Furnace

- 喂料系统: Automatically supplies rice husk into the furnace.

- Pyrolysis Chamber: Heats biomass to 400–600°C, breaking it down into biochar, 合成气, 和焦油.

- Gas Recycling Unit: Reuses combustible gases to fuel the furnace, reducing external energy needs.

- Discharge System: Cooled biochar is collected without interrupting production.

Why Rice Husk Is the Ideal Raw Material for Biochar

Turning Waste into Wealth

稻壳, a byproduct of rice milling, is abundant in Indonesia but often discarded or burned openly. 我们的continuous carbonization furnace for rice husk unlocks its potential by converting it into:

- 生物炭: Enhances soil fertility and carbon sequestration.

- Renewable Energy: Syngas can power generators or heat the furnace.

- 工业应用: Used in metallurgy, 水过滤, and cosmetics.

环境和经济效益

By processing rice husk into biochar, Indonesian farmers and factories can:

- Reduce waste and pollution from open burning.

- Generate additional income from biochar sales.

- Meet sustainability goals with carbon-negative production.

Weiwa’s Continuous Carbonization Furnace in Indonesia: Test Results

Real-World Performance Metrics

During a recent trial with Indonesian partners, our furnace achieved:

- 95% 炭化效率: Nearly all rice husk was converted into usable products.

- 24/7 Operation: Minimal downtime with automated controls.

- 低排放: Compliant with Indonesia’s environmental standards.

客户反馈

Indonesian clients praised the furnace’s low labor requirements和不错的投资回报率 (投资回报率), citing a 40% reduction in operational costs compared to traditional kilns.

Visit Weiwa’s Factory: See the Technology in Action!

Why Tour Our Facility?

We invite Indonesian clients to:

- Observe live demonstrations of rice husk carbonization.

- Discuss customization options for local needs.

- Network with our engineering team for technical support.

How to Arrange a Visit

Contact our sales team to schedule a factory tour and receive a free sample of rice husk biochar.

关于Weiwa机械

WEIWA机械 是领先的制造商charcoal and biomass processing equipment, 结束 30 多年的经验. 我们的连续碳化炉 are exported to 30+ 国家, offering innovative, eco-friendly solutions for waste recycling and energy recovery.

- 电话: +8613838093177

- 电子邮件: info@cjlmachinegroup.com

微信

微信