介绍

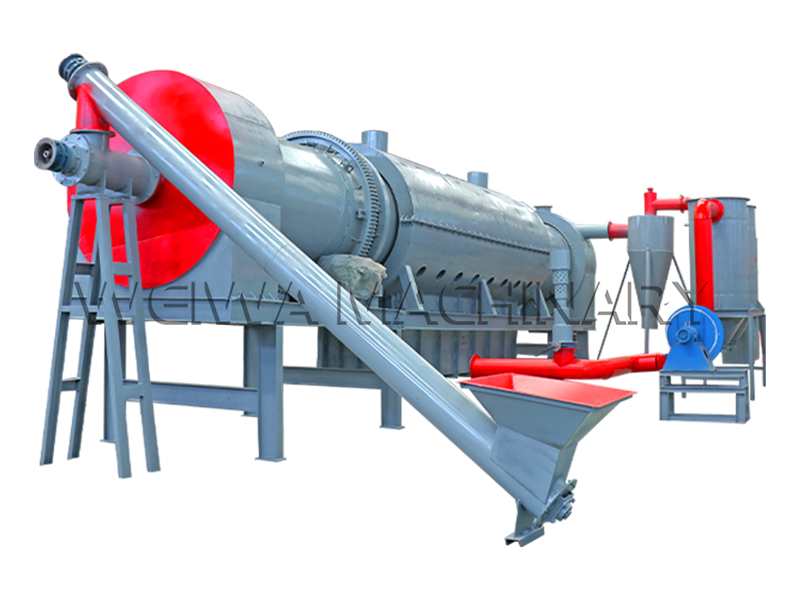

印度尼西亚农业部门产生大量有机废物, 包括澳洲坚果壳, 这代表了可持续能源和土壤增强的未开发的资源. 在WEIWA机械, 我们开创了先进连续碳化炉有效地将这些农副产品转化为的技术高品质生物炭——一种在农业中应用的有价值的产品, 活力, 和环境整治.

本综合指南探讨了:

- 连续碳化技术背后的科学

- 为什么澳洲坚果壳是理想的原料

- 来自印度尼西亚业务的真实绩效数据

- 我们系统的经济和环境效益

- 全球客户为何选择威瓦机械

我们向印尼企业发出公开邀请参观我们的生产设施并亲眼目睹我们的技术如何彻底改变您所在地区的生物质加工.

部分 1: 理解 连续碳化 技术

1.1 碳化科学

碳化是一种热化学过程,将有机材料转化为富含碳的固体 (生物炭) 通过热解——在缺氧环境中加热生物质. 传统间歇式碳化器存在以下问题:

- 温度控制不一致

- 劳动力要求高

- 批次之间有显着的热损失

我们的连续碳化炉通过以下方式克服了这些限制:

- 自动进料和出料系统

- 精确的温度调节 (400-600°C)

- 综合热回收技术

1.2 我们的连续系统如何运作

该过程分为四个优化阶段:

阶段 1: 预干燥区

- 温和加热传入的生物质以去除表面水分

- 准备有效热解的材料

阶段 2: 初级热解室

- 工作温度 450-550°C, 这是真正碳化发生的地方

- 挥发性化合物被去除,而碳基质仍然存在

阶段 3: 二次燃烧区

- 燃烧可燃气体以维持工艺热量

- 创建自我维持的能量循环

阶段 4: 冷却及收集

- 生物炭快速冷却以保持质量

- 自动分拣去除任何未加工的材料

部分 2: 为什么澳洲坚果壳是理想的原料

2.1 澳洲坚果壳的独特特性

我们的研究表明澳洲坚果壳具有独特的优势:

物理特性

- 异常坚硬的结构 (Janka 硬度 ~3,500 磅)

- 低水分含量 (<15% 在妥善存放的贝壳中)

- 高密度 (1.2-1.4 g/cm³)

化学成分

- 固定碳含量: 35-45%

- 挥发物: 50-55%

- 灰分含量: <2%

2.2 碳化性能优势

在我们的连续炉中加工时:

- 产量更高: 30-35% 转化为生物炭与. 20-25% 用于木材

- 卓越的产品品质: 固定碳 >85%

- 较低的能源需求: 15-20% 需要更少的燃料

部分 3: 印度尼西亚的实际表现

3.1 案例研究: 东爪哇试点项目

我们与印尼某农业合作社加工进行了90天的运营试验 8 吨/天澳洲坚果壳:

关键指标

| 范围 | 结果 |

|---|---|

| 正常运行时间 | 98.7% |

| 生物炭生产率 | 2.8 吨/天 |

| 能源消耗 | 85 千瓦时/吨 |

| 劳动力要求 | 1 操作员/班次 |

3.2 产品质量分析

独立实验室测试已确认:

- ph: 8.2-8.5 (酸性热带土壤的理想选择)

- 表面积: 280-320 平方米/克

- 阳离子交换容量: 45-50 分摩尔/千克

部分 4: 经济效益和环境效益

4.1 财务优势

我们的客户通常能够实现:

- 投资回收期: 6-8 月

- 投资回报率: 65-80% 前三年

- 增值机会:

- 优质生物炭销售 ($450-600/吨)

- 碳信用潜力

4.2 可持续发展影响

每个系统都提供:

- 减少二氧化碳排放: ~12 吨/天 vs. 露天焚烧

- 废物利用: 100% 转化的原料

- 土壤再生: 生物炭可提高保水性和养分利用率

部分 5: 全球客户为何选择 WEIWA机械

5.1 我们的技术优势

- 获得专利的多区域加热系统为了均匀碳化

- AI驱动的流程优化 不断提高效率

- 模块化设计 允许扩容

5.2 全面的支持包

我们提供:

- 现场安装调试

- 操作员培训计划

- 远程监控支持

- 年度维护合同

结论: 邀请您参与可持续创新

印尼丰富的澳洲坚果资源与威娃连续碳化技术的结合,为澳洲坚果行业创造了前所未有的机遇。:

- 农业合作社

- 可再生能源生产商

- 环境整治项目

我们邀请您参加:

- 安排工厂参观查看我们的技术的实际应用

- 提交您的生物质样本免费加工试用

- 咨询我们的工程师关于定制解决方案

请立即联系我们的印度尼西亚代表: [联系方式] 开始您的生物炭生产之旅.

电话/WhatsApp:+86 13838093177

电子邮件:info@cjlmachinegroup.com

微信

微信