木炭成型机介绍

木炭压球机, 例如 木炭挤压机, 对于将废物生物量或煤尘转换为高密度燃料棒至关重要. 这些机器因其成本效益和环境效益而在乌干达广泛用于家庭和工业应用.

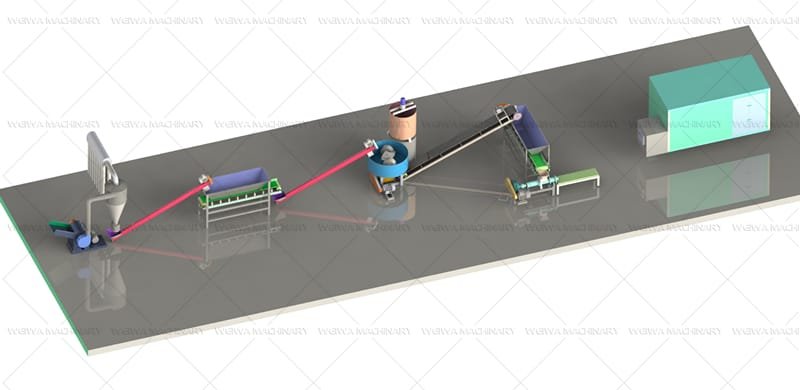

在WEIWA机械, 我们专注于制造高性能木炭挤出机, 锯末挤出机, 和 球板机机器 专为提高效率和耐用性而设计. 在这个博客中, 我们将探索这些机器的工作原理并分享最近的见解试运行我们的设备.

木炭挤出机如何工作?

关键部件 & 过程

a木炭挤出机 压缩原材料 (木炭粉, 煤尘, 或生物质) 在高压下, 迫使它们通过模具形成固体煤球. The process involves:

- 喂料系统: 原材料被送入机器的料斗中.

- 压缩 & 挤压: 螺旋输送机将物料推入压缩室, 高压形成致密的棒.

- 切割 & 烘干: 挤压棒被切割成一定尺寸并干燥以实现最佳燃烧.

我们还可以定制 生产线 根据客户的说法’ 要求.

为什么选择棒棒压球机?

棒状煤球具有多种优点:

- 更高的密度 延长燃烧时间.

- 降低烟雾排放与散装木炭相比.

- 更容易储存 & 运输由于形状统一.

维瓦木炭挤出机试运行: 主要发现

测试设置 & 参数

我们进行了真实世界的测试运行我们的木炭挤出机在乌干达典型的操作条件下. 测试重点是:

- 生产能力 (公斤/小时)

- 能源效率 (功耗)

- 煤球质量 (密度, 耐用性, 并燃烧时间)

绩效结果

我们的机器展示了:

- 输出效率高, 生产500-1000 公斤/小时 取决于材料水分.

- 低功耗, 使其对中小型企业具有成本效益.

- 稳定的煤球质量, 与密集的, 无裂纹棒,非常适合烹饪和工业用途.

影响乌干达木炭挤出机价格的因素

评估时制炭机价格, 考虑:

- 机器容量 (小规模 vs. 工业模型).

- 材料兼容性 (木炭灰尘, 木屑, 或农业废物).

- 售后支持, 包括安装和维护.

威瓦机械优惠有竞争力的定价 不影响质量, 确保乌干达客户获得丰厚的投资回报.

为什么选择 WEIWA机械?

与超过 30 多年的经验, 威瓦机械是煤球机制造领域值得信赖的品牌. 我们的专家技术团队提供:

- 定制化解决方案 根据您的生产需求量身定制.

- 现场安装 & 训练为了平稳运行.

- 可靠的售后支持, 包括备件和故障排除.

您是否需要一个木炭挤出机, 棒式压球机, 或完整的生产线, 威娃交付耐用的, 高性能设备 以合理的价格.

联系我们

WhatsApp/微信/电话:+86 13838093177

电子邮件:info@cjlmachinegroup.com

微信

微信