Relau karbonisasi mendatar untuk arang mekanisme adopts advanced hot gas flow carbonization technology, can carbonize Mechine-made Carbon Rods, greatly improve the carbonization rate,mudah dikendalikan,environmental protection and energy saving, can save a lot of energy,from the original carbonization rate of about 80% increased to 99%.

Unique Horizontal Carbonization Furnace for Mechanism charcoal Design

These are the main technical parameters of the product, if you do not know how to choose, you can tell us the raw materials you want to process. We will help you choose the best product for you.

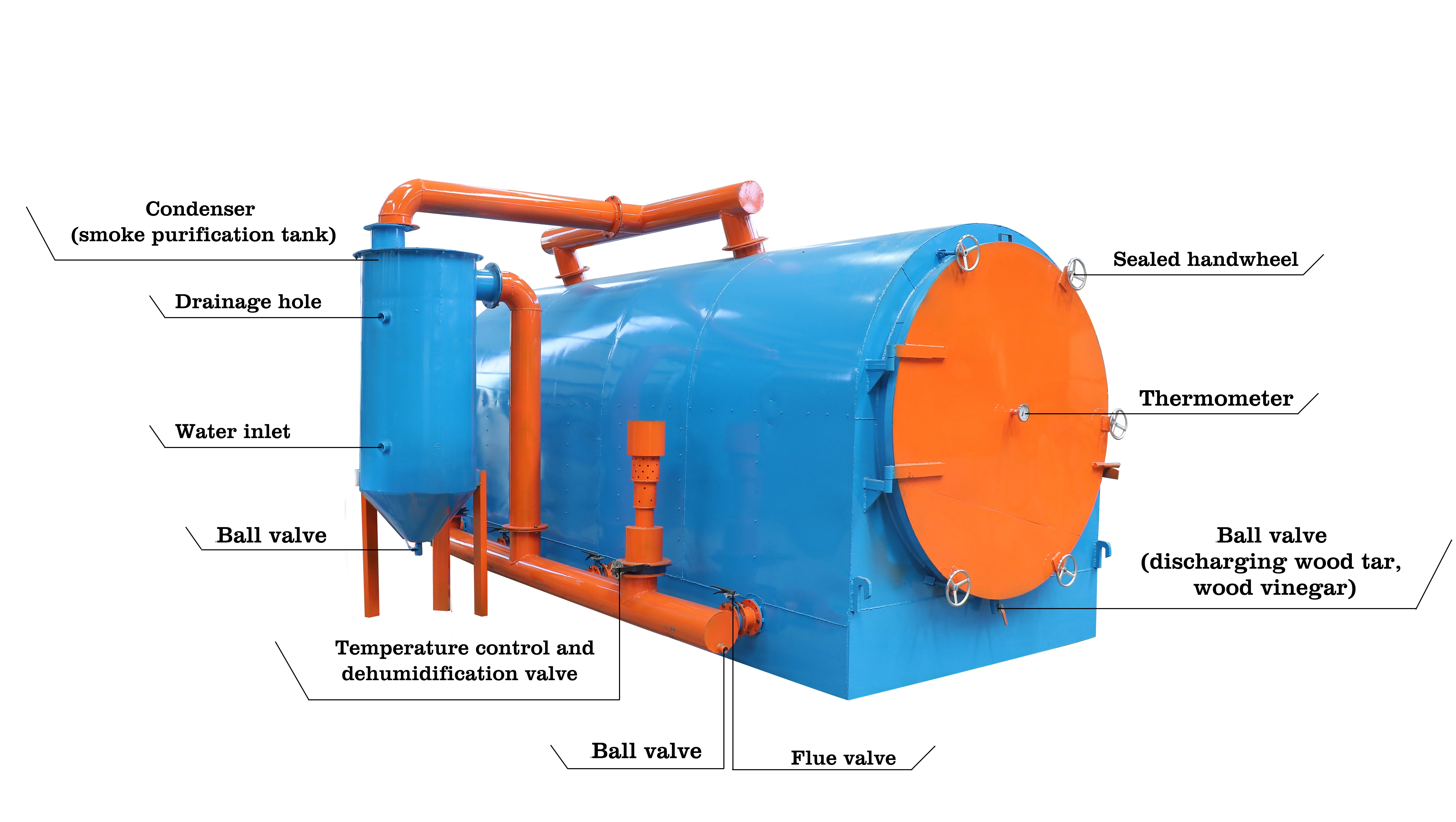

Thermometer : Measuring furnace temperature.

Sealing cap:Seal to maintain the temperature inside the furnace, to ensure into a good effect of carbonization.

Combustion Chamber: Fire the furnace and to make the charcoal. There is the combustible gas to produce and this gas can be sent to the bottom of the fire mouth to let the machine heat.

Carbonization Chamber:The raw materials are thermally decomposed in combustion chamber to generate a large amount of acetic acid, methanol, wood tar and other liquid products; also produced combustible gases such as methane and ethylene.

Smoke recovery system:The flammable gases are treated by flue gas purification, and are returned to the carbonization machine for burning, providing heat to the carbonization furnace, increasing the furnace temperature, and generating carbon at high temperatures.

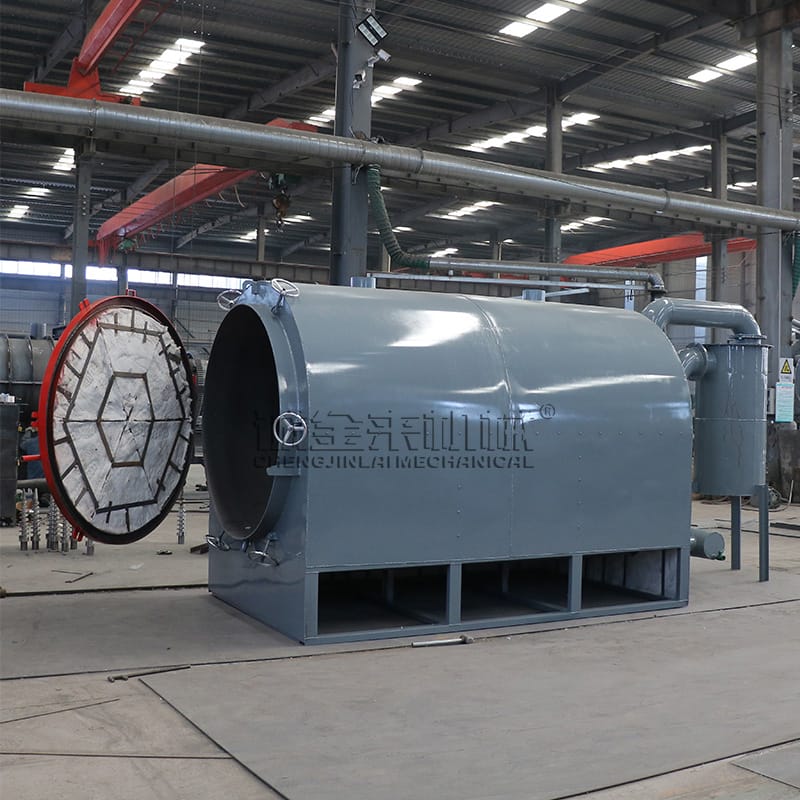

Convenient feeding and unloading

The horizontal carbonizing furnace is eguipped with rails and carts, which can make full use of the space in thefurnace, which is more convenient to use and reduces the labor intensity of workers.

What is the operating instructions of Horizontal Carbonization Furnace for Mechanism charcoal?

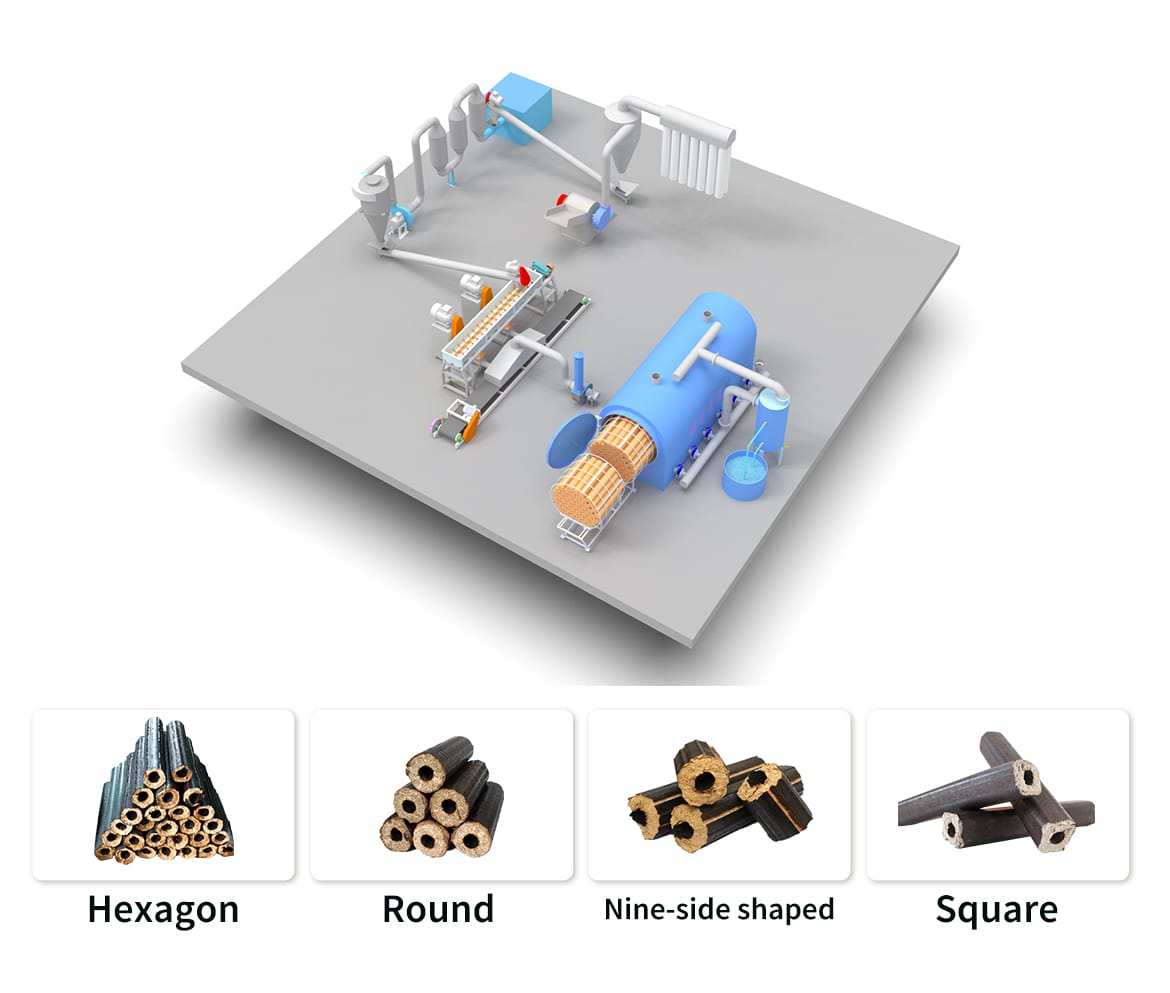

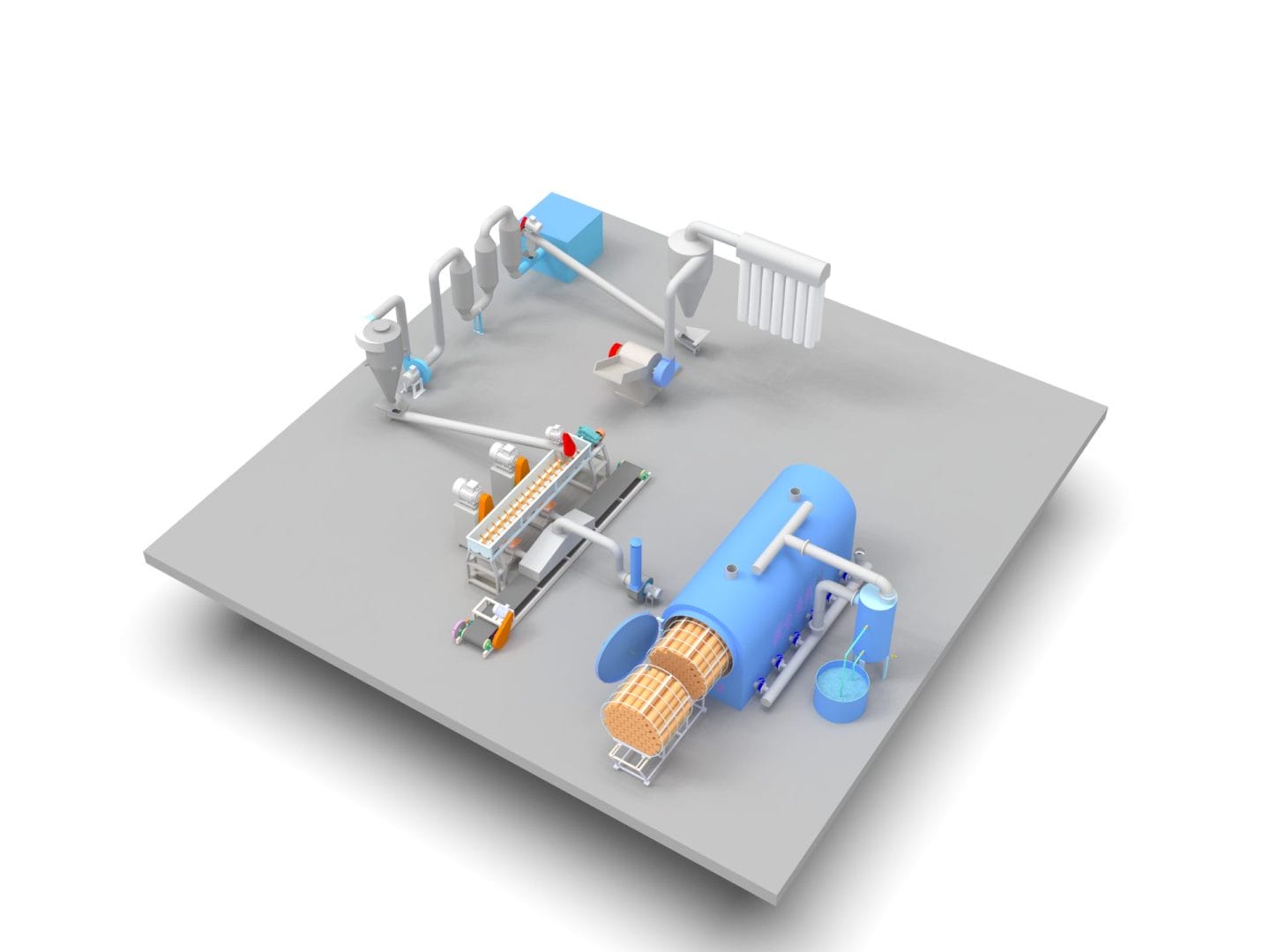

Work process of Horizontal Carbonization Furnace for Mechanism charcoal product line

- 1. Crush the raw material into a powder with a size of 2-5mm.

- 2. Use rotary dryer to make material dry until the moisture is 8%-12%.

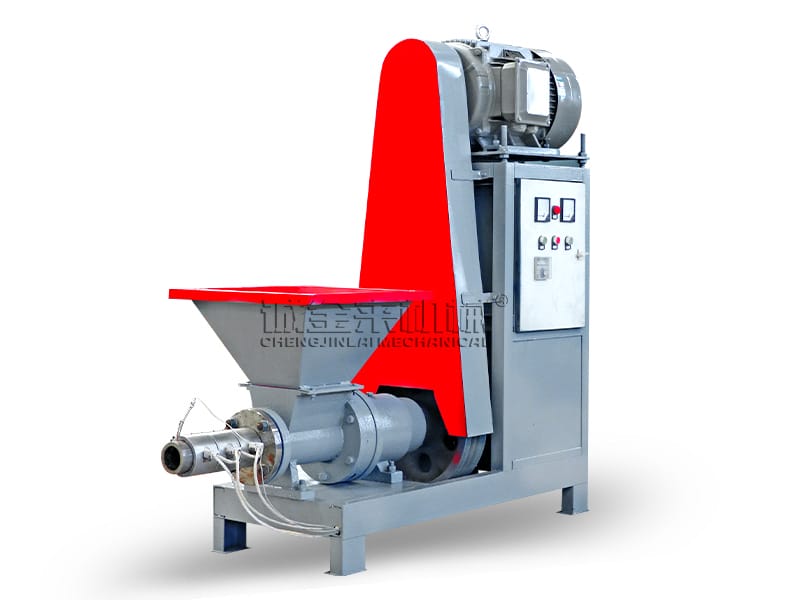

- 3. Use sawdust briquette equipment to moulding different shape and size of product.

- 4. After being pressed by the briquetting machine, it is finally placed in the carbonization furnace for carbonization it will become smokeless charcoal.

Related Posts:

Why do so many manufacturers choose Weiwa Horizontal Carbonization Furnace for Mechanism charcoal?

Stok

Kami mempunyai banyak stok,Kami dapat penghantaran dengan cepat.

diperakui

Kami telah mendapat banyak pemecahan,Oleh itu, anda tidak perlu bimbang tentang kualiti mesin kami.

Kilang

Kami adalah kilang,Kami dapat menyediakan mesin kualiti yang sama dengan harga yang lebih rendah.

Henan Weiwa Machinery Manufacturing Co., LTD. adalah pengeluar profesional mesin pembuatan arang di China. Penambahbaikan dan Inovasi Berterusan adalah falsafah pengeluaran kami. Prinsip kami: Bertahan dengan kualiti, berkembang dengan kredit, Kualiti pertama, kredit pertama, berasaskan integriti, Pelanggan Pertama.

WeChat

WeChat

+8613838093177

+8613838093177