The Rising Demand for Charcoal Briquettes in Thailand

Thailand’s shift toward sustainable energy and eco-friendly fuel solutions has driven a surge in demand for briket arang, particularly in households, restoran, and industrial sectors. As a result, manufacturers are increasingly seeking efficient charcoal extrude machinesdanrod briquette machines with cutters to produce high-quality, uniformly shaped briquettes.

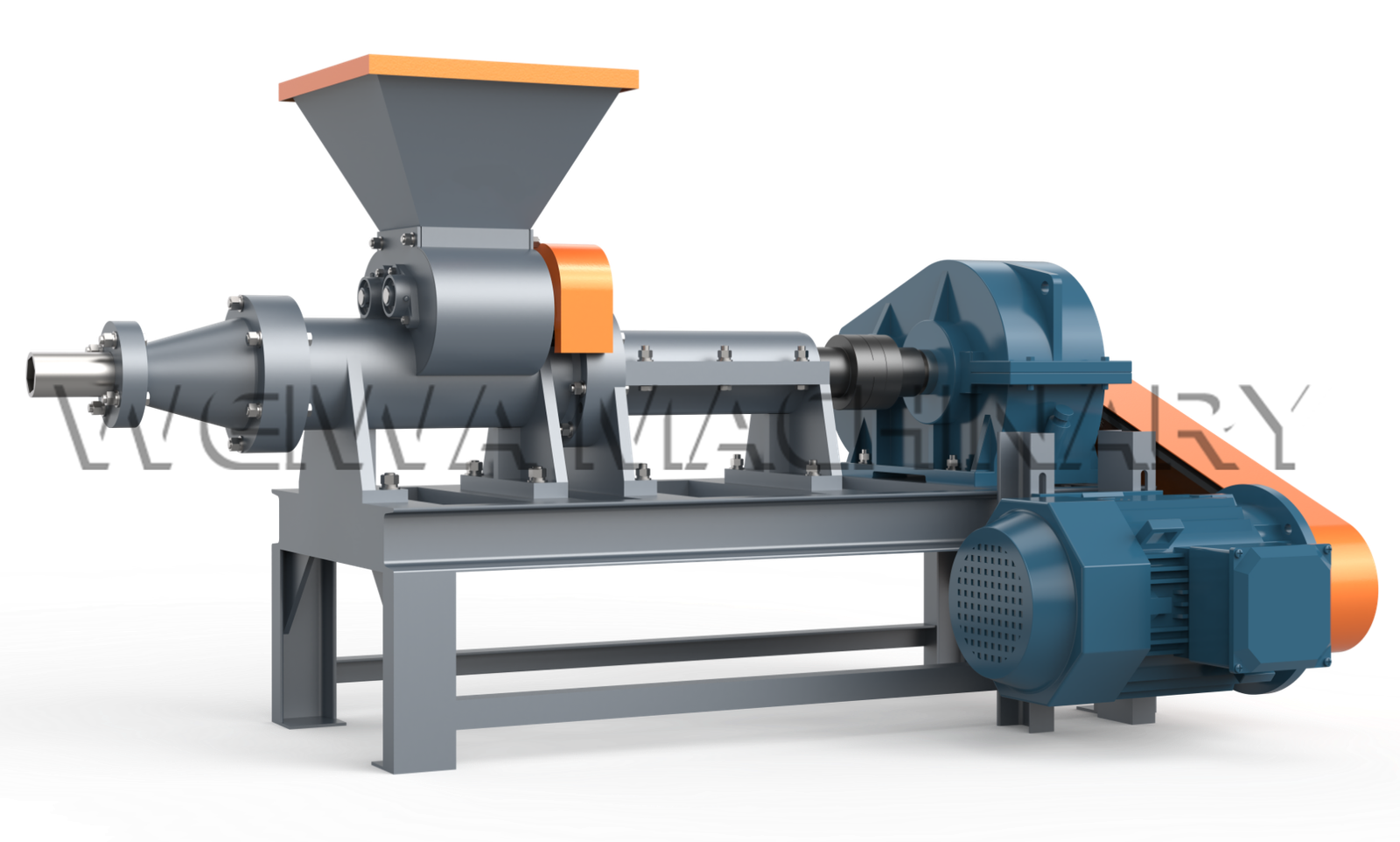

PadaJentera Weiwa, we recently conducted an on-site test of our charcoal extruder machine with cutter for a Thai client, demonstrating its efficiency, ketahanan, and cost-effectiveness.

How Charcoal Extruder Machines with Cutter Kerja?

The Role of Extruder Machines in Briquette Production

Acharcoal extrude machine (juga dipanggil acharcoal rod machine) compresses charcoal powder into dense rods or sticks using high pressure. These rods are then either air-dried or carbonized for use as fuel.

kamirod briquette machine with cutter takes this process further by automatically cutting the extruded rods into uniform lengths, ensuring consistency and reducing manual labor. This is especially beneficial for Thai manufacturers aiming for high production efficiency.

Why Thai Customers Prefer Cutter-Equipped Models?

- Precision Cutting: Ensures uniform briquette sizes for better burning efficiency.

- Labor Savings: Eliminates the need for manual cutting, mengurangkan kos operasi.

- Faster Production: Continuous extrusion and cutting enhance output speed.

Field Test in Thailand

Test Setup & Client Requirements

https://youtube.com/shorts/Cb2nP1xTiMc

Our Thai client, a medium-scale charcoal producer, needed a reliable charcoal extruder machine with cutter that could handle high-capacity production while maintaining low maintenance costs. We installed our rod briquette making machine in Thailand and conducted a 72-hour continuous test to evaluate its performance.

Performance Highlights

- Smooth Extrusion & Cutting

- The machine operated without jams, producing consistent charcoal rods with smooth surfaces.

- Thebuilt-in cutter precisely segmented the rods into 5cm lengths (adjustable based on client needs).

- Kecekapan tinggi & Low Downtime

- The machine processed 1-1.5 tons of charcoal powder per hour, meeting the client’s production goals.

- Minimal wear on components ensured long-term durability.

- Energy & Kecekapan kos

- The motor consumed moderate power, aligning with the client’s charcoal making machine price expectations for ROI.

- Reduced labor costs due to automation.

Charcoal Making Machine Price

Factors Influencing Cost

Theprice of a charcoal making machine varies based on:

- Kapasiti (small, medium, or large-scale production)

- Automation level (manual, semi-auto, or fully automatic with cutter)

- Material quality (stainless steel vs. carbon steel)

kamirod briquette machine with cutter offers competitive pricing while ensuring high durability and performance, making it a cost-effective solution for Thai manufacturers.

ROI for Thai Clients

- Production Capacity: 1-1.5 tons/hour → ~8-12 tons/day

- Market Price of Charcoal Briquettes in Thailand: ~1.20 per kg (depending on quality)

- Break-even Point: Typically within 6-12 months of operation.

Why Thailand is a Key Market for Rod Briquette Machines?

Growing Demand for Sustainable Fuel

- Hospitality & Restaurant Industry: High demand for clean-burning charcoal briquettes.

- Household Use: Consumers prefer tanpa asap, long-burning briquettes.

- Industrial Applications: Used in metallurgy and agriculture.

Local Manufacturing Trends

Thai entrepreneurs are investing in charcoal extruder machines to:

- Reduce reliance on imported charcoal

- Create value-added products from agricultural waste (cth., Kerang kelapa, wood scraps)

Weiwa Machinery’s Expertise in Charcoal Briquette Solutions

kamifield test in Thailand confirmed that our charcoal extruder machine with cutter delivers kecekapan tinggi, ketahanan, and cost savings for local manufacturers. Sama ada anda memerlukanrod briquette making machine in Thailand or a customized charcoal making solution, Weiwa Machinery provides:

Reliable machinery with proven performance

Competitive charcoal making machine price

On-site support & testing

Mengenai Jentera Weiwa

Jentera Weiwaialah pengeluar terkemukamesin briket arang, extruders, danbriquetting solutions with over 10+ tahun pengalaman in serving global clients. Kami pakar dalam:

- Charcoal extrude machines with cutters

- Rod briquette machines (manual, semi-auto, fully automatic)

- Penyelesaian tersuaiuntuk bahan mentah yang berbeza (kayu, shell kelapa, biojisim)

With a strong presence in Asia, Afrika, dan Asia Tenggara, we help clients boost production efficiency, mengurangkan kos, and transition to sustainable fuel solutions.

Hubungi kami hari ini for a konsultasi percuma or machine demo tailored to your needs in Thailand or beyond.

- Mob:+8613838093177

- WhatsApp:+8613838093177

- E-mel:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177