Pengenalan: The Rising Demand for Mechanical Shisha Charcoal Production

The global demand for shisha charcoal briquettes has surged in recent years, driven by the growing popularity of hookah smoking worldwide. Traditional methods of charcoal production are being replaced by mechanical charcoal press machines, which offer higher efficiency, consistency, and scalability.

PadaJentera Weiwa, kami pakar dalammechanical shisha press charcoal machines, mechanical charcoal briquette plants, and customized hookah charcoal production solutions. With over 30 years of industry experience, we help manufacturers optimize their production lines for berkualiti tinggi, uniformly shaped shisha charcoal briquettes.

Understanding Mechanical Shisha Press Charcoal Machines

What is a Mechanical Shisha Press Charcoal Machine?

Amechanical shisha press charcoal machine is a specialized piece of equipment designed to compress carbonized raw materials (such as coconut shells, kayu, or bamboo)ke dalamuniform shisha charcoal briquettes. Unlike traditional manual methods, these machines ensure:

✔Consistent shape and size (Hexagonal, round, or square)

✔Higher production speed

✔Reduced labor costs

✔Better density and burn time

kamimechanical charcoal briquette machines are engineered to handle different raw materials and produce hookah charcoal briquettes that meet international quality standards.

Types of Mechanical Charcoal Press Machines

Depending on production needs, Tawaran Jentera Weiwa:

- Mechanical hookah press charcoal machines (for small to medium-scale production)

- Fully automated shisha charcoal briquette plants (for large-scale industrial use)

- Customizable mechanical charcoal press plants (tailored to your specific requirements)

Each machine is built with durable materials, kejuruteraan ketepatan, and energy-efficient operation to maximize output while minimizing operational costs.

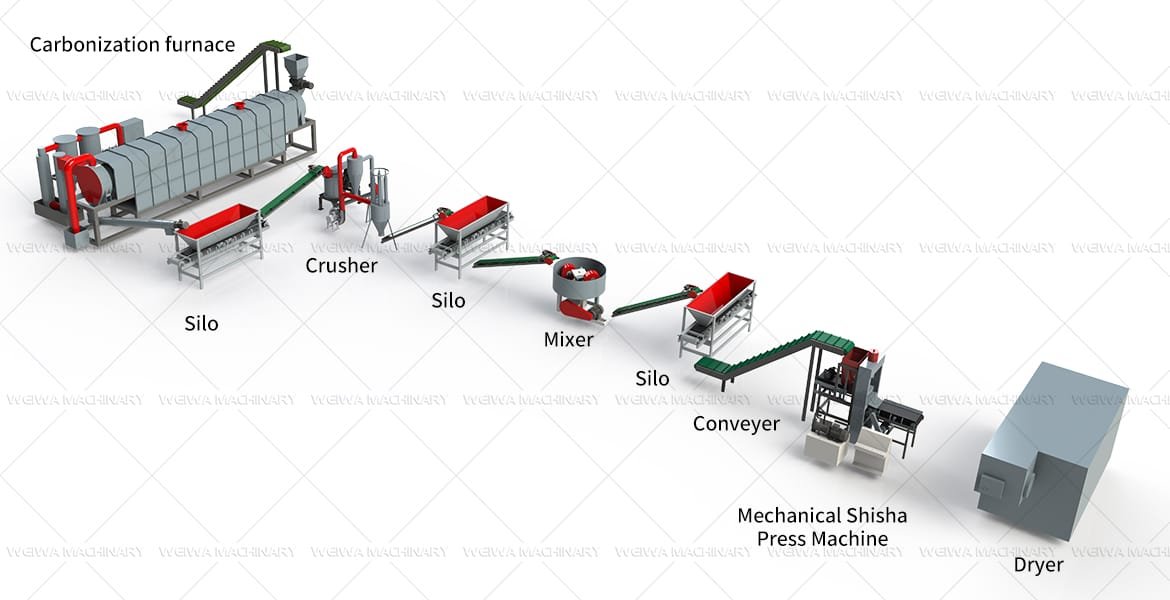

How to Produce Shisha Charcoal Using a Mechanical Press Machine

1. Raw Material Selection & Preparation

The first step in shisha charcoal production is selecting the right raw materials, seperti:

- Coconut shells (most common, burns clean and long)

- Hardwood sawdust (dense and high-quality)

- Buluh (eco-friendly alternative)

These materials are carbonized (heated in a kiln or furnace to remove moisture and volatile compounds), resulting in charred biomass that is ready for briquetting.

2. Menghancurkan & Percampuran

The carbonized raw materials are then crushed into fine powder and mixed with a natural binder (such as starch or gum arabic) to ensure proper binding during compression.

3. Briquetting with a Mechanical Shisha Press Charcoal Machine

This is where our mechanical charcoal briquette machine comes into play. The powdered mixture is fed into the machine, which applies high pressure to form dense, uniformly shaped briquettes.

Key advantages of using our mechanical press:

- Precise pressure control for optimal density

- Adjustable molds for different briquette shapes (Hexagonal, round, Dataran)

- High output rate (suitable for both small and large-scale production)

4. Drying the Briquettes

Freshly pressed briquettes contain some moisture and must be dried (either in a natural sun-drying process or using a mechanical dryer) to achieve the right hardness and burn efficiency.

5. Pembungkusan & Distribution

Once dried, the shisha charcoal briquettes are packaged (usually in foil or paper bags) and ready for global distribution.

Why Shisha Charcoal Production is a Lucrative Business

Theglobal shisha charcoal market is experiencing rapid growth due to:

Increasing hookah smoking popularity (especially in the Middle East, Europe, and North America)

Demand for premium, clean-burning charcoal (consumers prefer coconut-based briquettes)

Shift from traditional charcoal to machine-made briquettes (for consistency and quality)

By investing in a mechanical charcoal press plant, manufacturers can:

- Produce high-quality shisha charcoal at scale

- Meet international export standards

- Achieve higher profit marginsberbanding kaedah tradisional

Weiwa Machinery helps businesses set up efficient production lines with our customized mechanical charcoal briquette solutions.

Why Choose Weiwa Machinery for Your Shisha Charcoal Production?

denganberakhir 30 tahun pengalaman in the machinery industry, Jentera Weiwa is a trusted name in mechanical charcoal press machines dan briquette production plants. Here’s why clients worldwide partner with us:

✔ Expertise & Reliability

We specialize in designing and manufacturing high-performance mechanical shisha press charcoal machines that deliver consistent results.

✔ Customized Solutions

Every business has unique needs. We offer customized design drawings, factory layout planning, and tailored machinery to match your production goals.

✔ Professional After-Sales Support

kamidedicated after-sales teammenyediakantechnical support, maintenance guidance, and spare parts availabilityuntuk memastikan operasi berjalan lancar.

✔ Global Reach & OEM/ODM Services

We serve clients in berakhir 50 negara, offering OEM/ODM services for brands looking to establish their own barisan pengeluaran arang.

Welcome to cooperate with Jentera Weiwa!

denganberakhir 30 years of industry experience, Jentera Weiwaialah pengeluar terkemukamechanical charcoal press machines, briquette production lines, and custom industrial equipment. Kami pakar dalam:

- High-quality mechanical shisha press charcoal machines

- Customized factory layout & design services

- Professional after-sales support & spare parts supply

kamiexpert team ensures efficient production, ketahanan, and optimal performance for every client. Sama ada anda memerlukansmall-scale hookah charcoal press or a full-scale briquette plant, Weiwa Machinery is your trusted partner.

Contact us today for inquiries, quotes, or customized solutions!

- Mob:+8613838093177

- WhatsApp:+8613838093177

- E-mel:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177