Meeting Indonesia’s Growing Demand for Charcoal Production

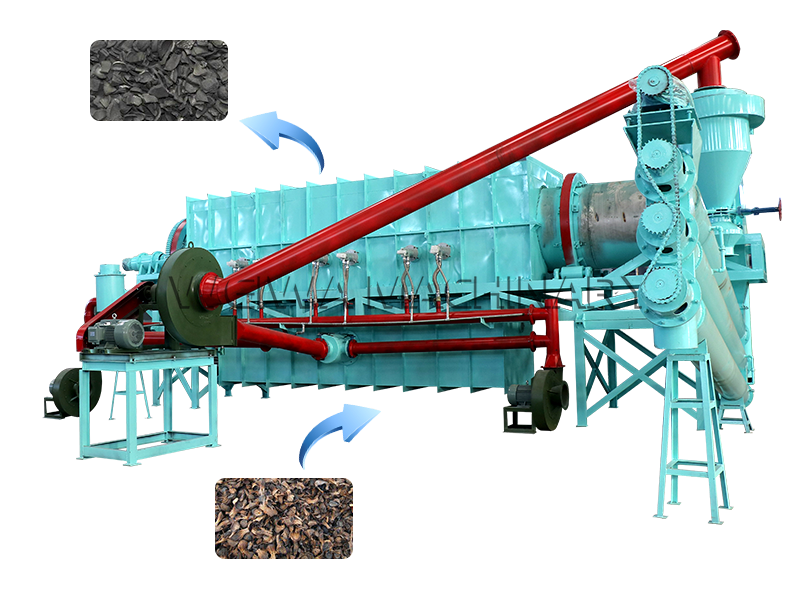

Indonesia, with its vast palm oil industry, generates significant amounts of palm fiber—a byproduct that holds immense potential for charcoal production. Our client, based in Indonesia, approached Jentera Weiwa with a clear goal: to carbonize palm fiber using our relau karbonisasi berterusan and then process the resulting charcoal into hookah charcoal using a hydraulic press.

However, the high tar content in palm fiber posed a major challenge—leading to frequent pipeline blockages during the carbonization process. Through close collaboration, our engineering team conducted on-site debugging in Indonesia, upgrading the relau karbonisasi berterusanuntuk memastikan operasi berjalan lancar.

Why Continuous Carbonization Furnaces Are Ideal for Palm Fiber?

The Rise of Palm Fiber as a Charcoal Feedstock

Palm fiber, a fibrous residue from palm oil production, is often discarded or underutilized. However, when carbonized, it transforms into high-quality charcoal with excellent energy density—making it perfect for hookah charcoal, BBQ briquettes, dan aplikasi perindustrian.

kamicontinuous carbonization furnace for palm fiber offers:

- High efficiency with continuous feeding and discharging

- Stable temperature control for optimal carbonization

- Low emissionsdanenergy-saving design

Indonesia’s Need for Reliable Carbonization Technology

With Indonesia being one of the world’s largest palm oil producers, there’s a growing demand for sustainable charcoal solutions. kamicontinuous carbonization furnace in Indonesia helps local businesses convert waste into profit while meeting environmental regulations.

Tar Buildup and Pipeline Blockages

Why Palm Fiber Causes Blockages

Palm fiber contains a high concentration of lignin and natural oils, which decompose during carbonization to form sticky tar. This tar can:

- Coat the inner walls of the furnace and pipes

- Solidify and obstruct airflow

- Reduce carbonization efficiency

Our initial tests showed that without modifications, the relau karbonisasi berterusan would require frequent shutdowns for cleaning—leading to downtime and reduced productivity.

Our On-Site Debugging Process in Indonesia

Our team traveled to the client’s facility to:

- Analyze the carbonization flow and identify blockage points

- Inspect the furnace’s internal structure for tar accumulation

- Test different temperature and feeding rates to minimize tar formation

Upgraded Pipeline Design for Smoother Operations

Key Modifications to the Continuous Carbonization Furnace

To combat tar buildup, we implemented three major upgrades:

1. Reinforced Internal Lining & Sloped Pipelines

- We adjusted the angle of the pipelines to allow tar to flow more naturally toward collection points.

- Added heat-resistant lining to prevent tar adhesion.

2. Enhanced Airflow & Ventilation System

- Improved gas circulation to reduce tar condensation.

- Installed additional vents to release excess tar vapors before they solidified.

3. Automated Tar Collection Mechanism

- Introduced a secondary condensation chamber to capture tar before it reached critical pipes.

- This ensured cleaner gas flowdanlonger operational periods without clogging.

Results After the Upgrade

- Reduced blockages by over 80%

- Increased continuous operation time from 6 hours to 24+ jam

- Higher charcoal yield with better quality

From Carbonization to Hookah Charcoal

Langkah 1: Carbonizing Palm Fiber in the Continuous Furnace

- The palm fiber is fed continuously into the furnace at controlled temperatures (450–600°C).

- Thecontinuous carbonization process ensures uniform heating and minimal tar retention.

Langkah 2: Menghancurkan & Mixing the Charcoal

- The resulting palm fiber charcoal is crushed to a fine powder.

- Abinding agent (jika perlu) is mixed for optimal compression.

Langkah 3: Hydraulic Pressing into Hookah Charcoal

- The powdered charcoal is compressed using a hydraulic presske dalamuniform hookah briquettes.

- Our client reported higher durability and better burning performance compared to traditional charcoal.

Why Choose Weiwa Machinery for Your Carbonization Needs?

denganberakhir 30 tahun pengalaman in biomass carbonization, Jentera Weiwa is a trusted partner for clients in Indonesia and beyond. Here’s what sets us apart:

Customized Solutions

- We design relau karbonisasi berterusan tailored to your raw materials (palm fiber, kayu, Kerang kelapa, dll.).

- Our engineers provide detailed planning, drawings, and on-site support.

Professional After-Sales Service

- Our team offers remote troubleshootingdanon-site debugging when needed.

- We ensure smooth operation from installation to daily use.

Proven Track Record in Indonesia

- We’ve successfully deployed relau karbonisasi berterusan for multiple Indonesian clients, helping them turn waste into profitable charcoal products.

Overcoming Challenges, Delivering Results

The journey from palm fiber to hookah charcoal is not without hurdles—especially when dealing with high tar content. However, through innovative engineering and on-site collaboration, Jentera Weiwa delivered a reliable continuous carbonization furnace that now operates efficiently in Indonesia.

If you’re looking for a customized carbonization solution for palm fiber, kayu, or other biomass, our team is ready to help.

Mengenai Jentera Weiwa

dengan30+ tahun kepakaran in charcoal making machines and carbonization technology, Jentera Weiwa specializes in designing, pembuatan, and installing continuous carbonization furnaces for global clients. kamipasukan selepas jualan profesional ensures smooth operation, and we offer Penyelesaian yang disesuaikan with detailed planning and on-site support.

Hubungi kami hari ini untuk konsultasi dan sebutharga percuma!

- Mob:+8613838093177

- WhatsApp:+8613838093177

- E-mel:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177