Introduction to Bio Coal Briquettes

In the quest for sustainable energy solutions, briket arang batu bio telah muncul sebagai penukar permainan. Alternatif bahan bakar mesra alam ini, diperbuat daripada arang batu biomas dan berkualiti rendah, offer a renewable energy source with reduced carbon footprints. As global industries pivot toward greener practices, understanding the bio coal briquettes manufacturing plant cost becomes critical for businesses aiming to invest in this booming sector.

PadaJentera Weiwa, we specialize in designing cost-effective, high-performance briquetting solutions tailored to meet diverse production needs.

Key Factors Influencing Bio Coal Briquettes Manufacturing Plant Cost

1. Raw Material Availability and Preparation

The cost of raw materials significantly impacts overall expenses. Bio coal briquettes typically blend biomass (sisa pertanian, forestry residues, or fermented cow dung) with low-quality coal. Key considerations include:

- Biomass Procurement: Locally sourced materials like rice husk, habuk papan, or straw reduce transportation costs. Fermented biomass (cth., cow dung treated with bio-activators) may require additional pre-processing but enhances calorific value.

- Coal Quality: Low-sulfur coal (cth., 0.51 wt% sulfur content) minimizes environmental compliance costs, while high-sulfur coal demands extra treatment steps.

- Pre-Treatment Costs: Pengeringan, shredding, and torrefaction (thermal treatment to improve energy density) add 15–20% to raw material expenses.

2. Equipment Selection and Automation

Investing in the right machinery is crucial for optimizing production efficiency. Key equipment includes:

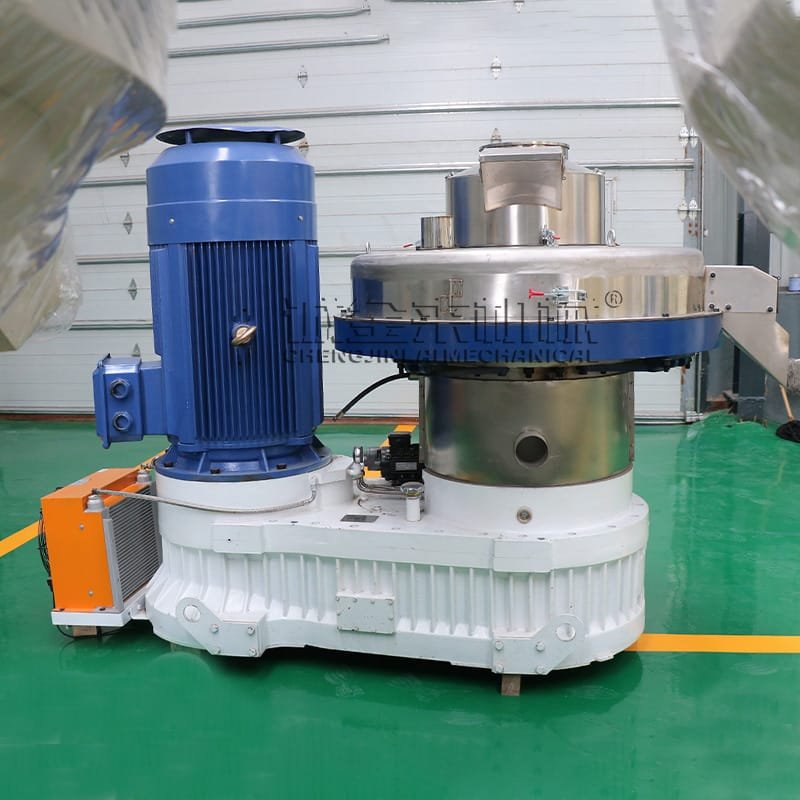

Mesin Pembuatan Pelet Kayu Biomas

Briquetting Machines:

- Screw Briquette Presses: Ideal for continuous production (1–5 tons/hour), these automated systems suit large-scale operations but require higher upfront costs.

- Hydraulic/Pneumatic Presses: Lower energy consumption and compact design make them cost-effective for small to medium plants.

- Auxiliary Systems: Dryers, mixers, dan carbonization kilns (for converting biomass into charcoal) add 25–30% to the total plant cost.

Di Weiwa Machinery, kamiBiomass briquetting line combines automated screw presses with energy-efficient dryers, reducing operational costs by 20% compared to conventional setups.

3. Labor and Operational Expenses

Labor costs vary based on automation levels. Semi-automated plants require 8–10 workers per shift, while fully automated systems cut labor needs by 60%. Energy consumption (1,000–1,500 kWh/ton) dan penyelenggaraan (cth., replacing wear-resistant parts in presses) also contribute to ongoing expenses.

Market Opportunities and ROI Potential

The global bio coal market, valued at $140.08 bilion dalam 2023, is projected to grow at a 5.19% CAGR through 2029. Key drivers include:

- Government Incentives: Subsidies for renewable energy projects and carbon tax exemptions improve ROI.

- Industrial Demand: Steel, cement, and power industries increasingly adopt bio coal to reduce CO₂ emissions (cth., 145 kg/ton reduction in blast furnaces).

A mid-sized plant (5 tan/jam) typically achieves breakeven within 2–3 years, with profit margins exceeding 25% post-breakeven.

Why Choose Weiwa Machinery?

With over 30 years of expertise in biomass processing, Weiwa Machinery delivers end-to-end solutions for bio coal briquette production:

- Customized Designs: From compact batch systems to fully automated lines, we tailor equipment to your budget and output goals.

- Energy-Efficient Technology: Our machines consume 30% less power than industry averages, lowering operational costs.

- Global Support: With installations in 30+ negara, kami sediakan 24/7 technical assistance and spare parts supply.

Contact Us Now

Ready to revolutionize your energy strategy with bio coal briquettes? Contact Weiwa Machinery today for a free consultation and customized cost estimate. Let’s build a sustainable future together!

📞 Phone/WhatsApp: +8613838093177

📧 Email: info@cjlmachinegroup.com

🌐 Website: https://cjljx.com/product/biochar-production-equipment

WeChat

WeChat

+8613838093177

+8613838093177