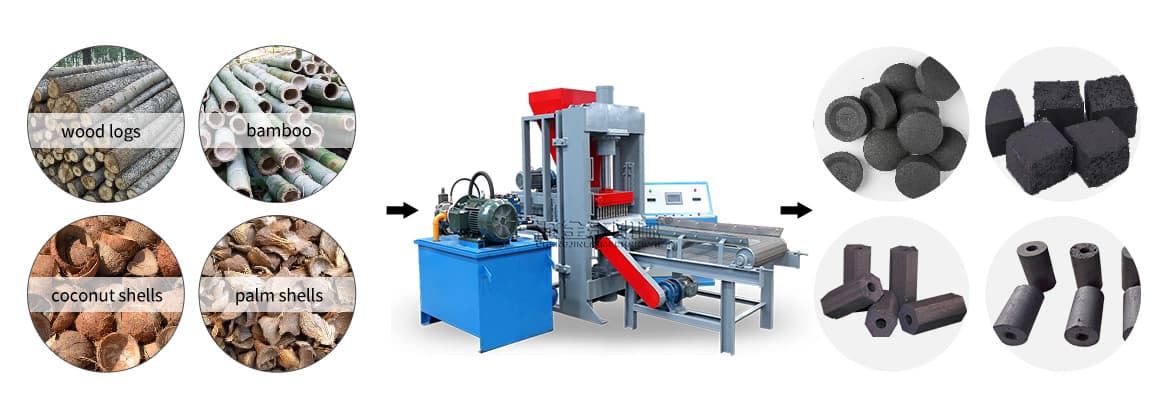

Ligne de production de briquettes de charbon de bois pour chicha, matières premières et produits finaux

La ligne de production de briquettes de charbon de bois pour chicha propose une large gamme de matières premières,comme les bûches en bois, bambou, coquilles de noix de coco, coquille de palme, copeaux de bois, coccarbures de riz, coquilles de noix, coquilles de noix et diverses matières premières de biomasse.

Avantages du charbon de bois

Le processus est caractérisé par capacité de production élevée, haut degré d'automatisation, haute qualité du produit, économies d'énergie, protection de l'environnement, faible émission de substances nocives et taux d'utilisation élevé de poudre de métal/mine industrielle.

Et les avantages du charbon de bois sont Longue durée de combustion, valeur calorifique élevée, pas de fumée, pas d'explosion, protection de l'environnement et économie.

Champs applicables au charbon de bois

Le charbon de bois peut être utilisé pour la combustion domestique, chaudières, barbecues, chauffage de cheminée, centrales électriques et autres aspects.

En outre, En raison de sa structure microporeuse unique et de sa capacité d'adsorption, Il est largement utilisé dans de nombreux domaines tels que la nourriture, pharmacie, industrie chimique, métallurgie, Défense nationale, Agriculture et protection de l'environnement.

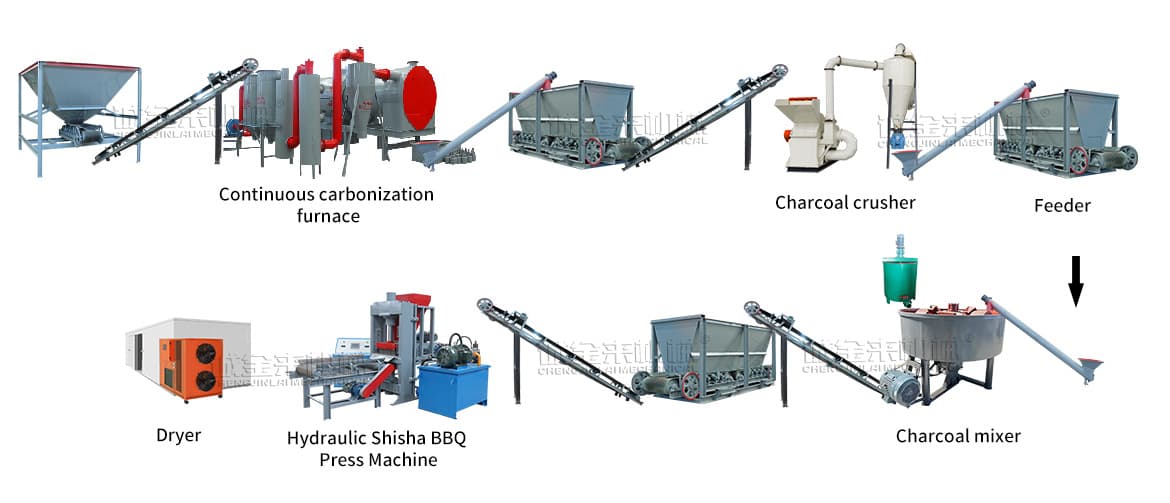

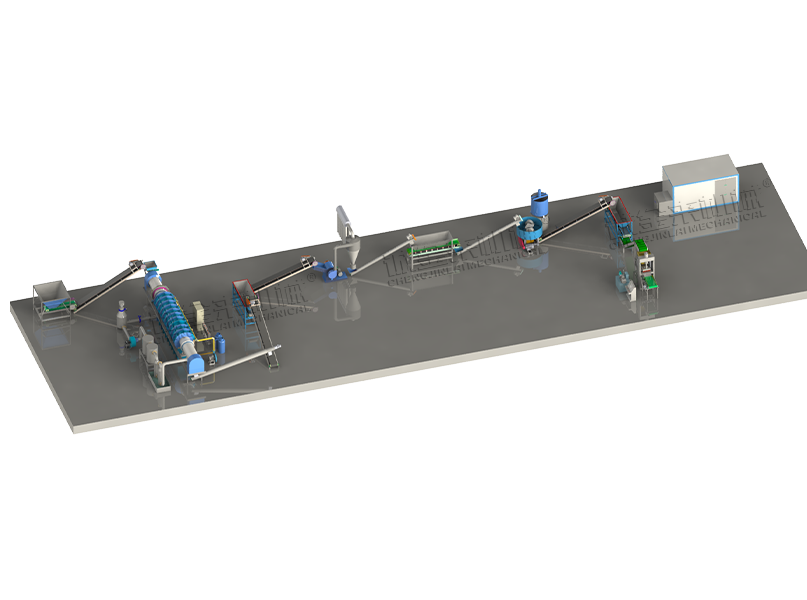

Flux de processus de la ligne de production de briquettes de charbon de bois pour chicha

Vous pouvez maintenant voir grosso modo la chaîne de production, la ligne de production exacte est conforme à vos besoins.

Matières premières—- Four de carbonisation —- Broyeur à charbon de bois—- Mélangeur de liant—- Moulin à roues—- Machine de charbon de bois Shisha—- briquettes de charbon de bois pour chicha finies—- Séchoir

A. Le broyeur à double bouche est le principal équipement de broyage des matières premières dans le processus de production de briquettes de charbon de chicha. C'est un équipement de concassage fin..

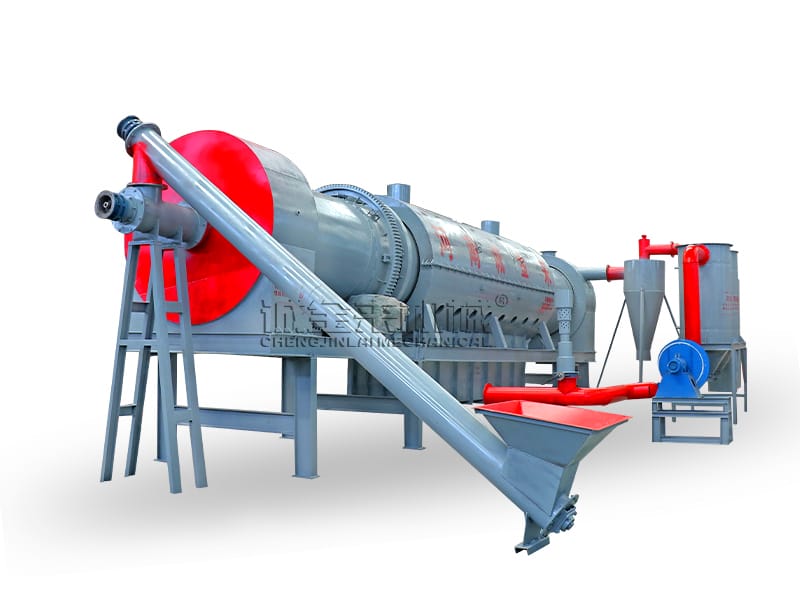

B. Le séchoir à tambour rotatif est le principal équipement de séchage des matières premières dans le processus de production de briquettes de charbon de chicha., qui est fiable en fonctionnement, Flexible en fonctionnement, fort dans l'adaptabilité, et grande capacité de traitement. Le diamètre et la longueur de l'équipement sont déterminés en fonction des exigences de séchage.

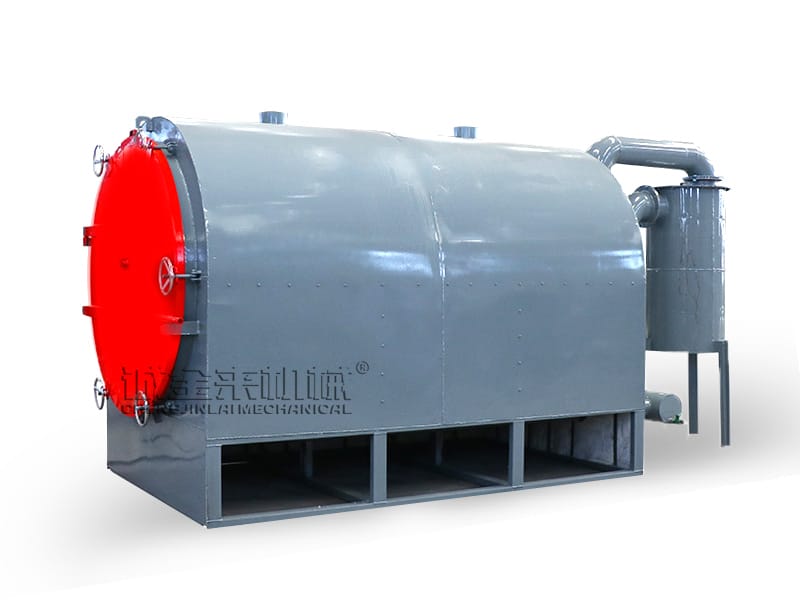

C. Le four de carbonisation continue est largement utilisé dans divers domaines de traitement et de production de charbon de bois. C'est l'un des équipements importants pour la chaîne de production de briquettes de charbon de chicha..

Le moulin D.Hammer est le principal équipement de concassage des matières premières dans le processus de production de briquettes de charbon de chicha qui peut traiter toutes sortes de bois., restes de bois, branches, branches, copeaux de bois, garniture de planche, aboyer, bambou, Écorce de bambou et autres matières premières en sciure à la fois.

Le mélangeur à moulin à roues est un modèle qui combine le broyage et le mélange de roues conçus en fonction des avantages du dernier équipement de fraisage et de mélange de roues étrangères. Convient pour mélanger la poudre et les matériaux granulaires, comme la poudre de carbone, poudre de charbon, argile, boue réfractaire, sable de queue, scories, sable de moulage, etc..

F.Adhésive Le canon de mélange est entraîné par la ceinture de triangle moteur pour conduire la roue à tourner, et l'eau et le liant sont entièrement mélangés uniformément. C'est un dispositif nécessaire pour augmenter le temps de réaction de l'agent et renforcer la qualité de réaction du matériau.

La machine à briquettes de charbon de bois G.Shisha est un équipement de moulage important dans le processus de production de briquettes de charbon de bois pour chicha. Cet équipement peut presser du charbon bleu, poussière de coke, poudre de charbon de bois, poudre de cendre, engrais et autres poudres.

Notre équipe d'ingénieurs peut fournir une conception gratuite de ligne de production

Lorsque vous prévoyez de configurer une ligne de production de carbonisation, Veuillez nous faire part de vos coordonnées.

Ces matériaux comprennent:

1.Type de matière première, taille, humidité

2.Taille de l'usine

3.Capacité du transformateur

4.Type et taille du produit fini

5.Demande de production

Aussi détaillé que possible, le meilleur, Afin de personnaliser votre propre équipement de ligne de production de carbonisation, Et nous vous fournirons gratuitement des diagrammes de planification du site 3D.

*Différents matériaux seront conçus dans une solution de production différente, Le client au moment de la consultation doit nous informer des documents’ humidité, taille des particules, rendement, taille des briquettes, forme, Certaines circonstances particulières ont peut-être besoin d'équipements auxiliaires tels que d'autres types de concasseur,Autres types de mélangeurs,maille d'écran, tamis de vibration, département de liant, réservoir de mélange de liquide, séparateur magnétique, Palenteuse de ceinture électronique, entraînement à fréquence variable.

Related Posts

Wechat

Wechat

+8613838093177

+8613838093177