La demande croissante de machines à charbon de bois en Malaisie & Asie du Sud-Est

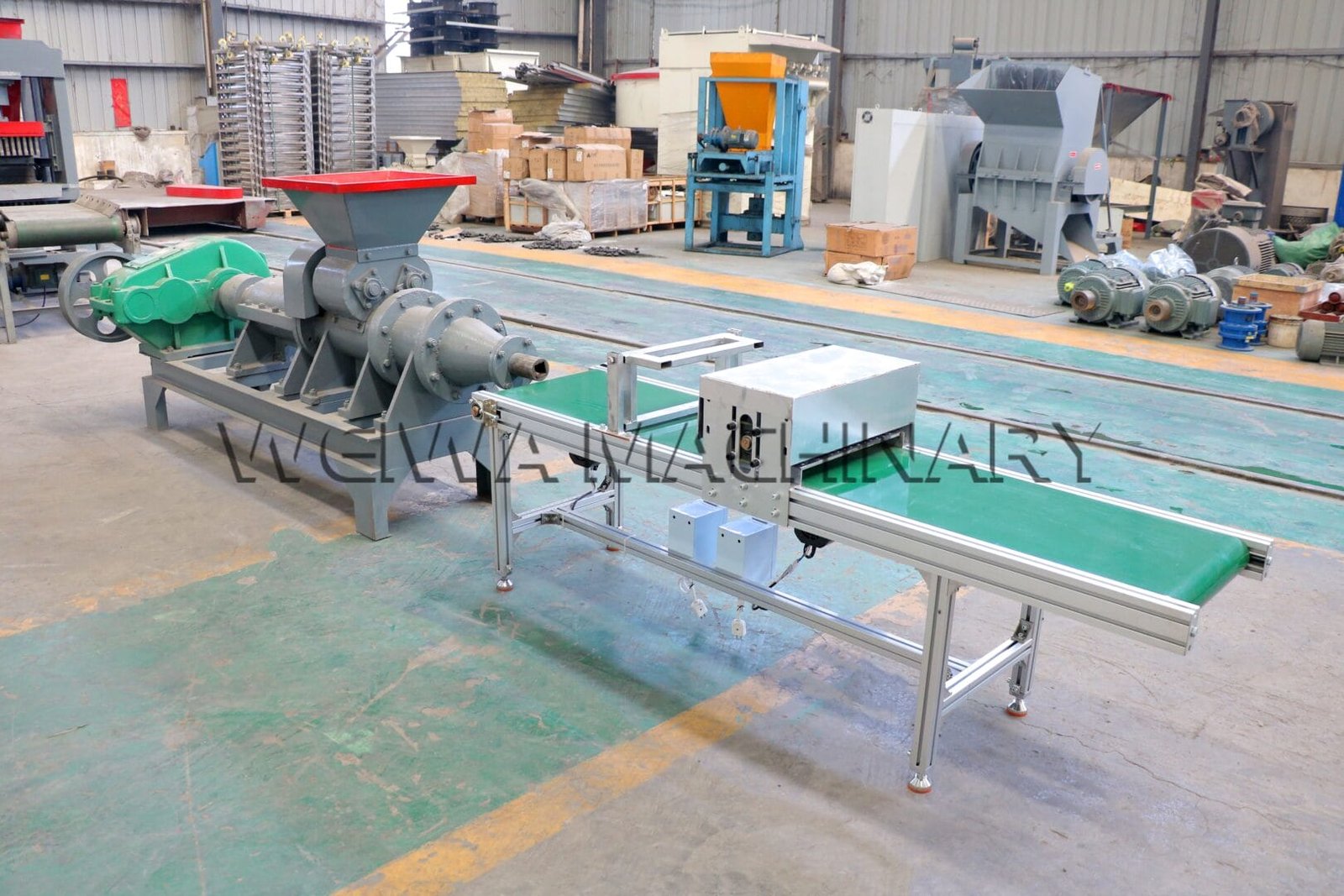

Au cours des dernières années, Malaysia and Southeast Asia have seen a surge in demand for charcoal briquettes and rods, driven by the growth of BBQ culture, chauffage industriel, et des alternatives de carburant respectueuses de l'environnement. En tant que fabricant leader, Machinerie Weiwa has been actively testing our extrudeuse de charbon de bois avec coupeurEtrod briquette machine with cutter in local conditions to optimize performance for Malaysian clients.

Why Cutter-Integrated Charcoal Machines Matter in Malaysia?

The Challenge: Coupe manuelle vs. Automated Efficiency

Traditional charcoal extruder machines produce continuous rods that require manual cutting, conduisant à:

- Inconsistent lengths (affectant l'efficacité de la combustion).

- Wasted raw materials (mauvaise taille).

- Slower production rates (à forte intensité de main-d'œuvre).

NosCharcoal Extruder Machine with CutterEtRod Briquette Machine with Cutter solve these issues by automatically slicing rods to precise lengths (Par exemple, 40MM, 60MM, or custom sizes), garantissant:

Uniform burning performance

Higher output per hour

Reduced labor costs

Weiwa’s Cutter-Equipped Machine Field Test in Malaysia

Test Setup: Emplacement & Client Profile

We deployed our latest charcoal extruder with cutter à un Malaysian charcoal producer specializing in coconut shell briquettes. Their key requirements:

- High-capacity production

- Consistent rod diameter

- Temps d'arrêt minimal.

Performance Highlights

- Seamless Cutting Mechanism

- Lecoupeur intégré ensured zero jamming even with dense coconut shell charcoal.

- Adjustable speed control allowed custom-length rods (40mm–100 mm) based on client needs.

- Production plus rapide & Labor Savings

- Before: Manual cutting required 2 workers → After: Fully automated, reducing manpower needs.

- Output increased by 30% sans compromettre la qualité.

- Durability in Tropical Conditions

- Malaysia’s high humidity posed no rusting issues, thanks to Weiwa’s powder-coated steel frame.

Prix de la machine de fabrication de charbon de bois

A common concern among Malaysian clients is the Prix de la machine à fabriquer du charbon de bois. While cutter-equipped models may have a slightly higher upfront cost, lelong-term ROI is clear:

- Lower labor expenses (fewer workers needed).

- Réduction des déchets (precise cutting minimizes offcuts).

- Faster payback period (higher daily output).

Offres Weiwacompetitive pricingAveccustomizable features (Par exemple, diesel/electric motor options) to fit Malaysia’s budget ranges.

Why Weiwa’s Cutter-Integrated Machines Lead in Southeast Asia?

1. Localized Support & After-Sales Service

Contrairement aux fournisseurs de génériques, Weiwa provides:

- On-site installation training in Malaysia.

- Spare parts availability within 72 heures.

2. Customization for Regional Needs

- Diameter adjustments (for coconut shell, bois, or biomass).

- Voltage compatibility (Malaysia’s 3-phase power systems).

3. Expérience éprouvée

Our machines are already operational in Malaisie, Indonésie, Thaïlande, et le Viêt Nam, avec95% client retention.

Is a Cutter-Equipped Charcoal Machine Right for Your Business?

If you’re a Malaysian charcoal producer looking to:

✔Boost efficiency (automated cutting).

✔Réduire les déchets & labor costs.

✔Sell premium, uniformly sized briquettes,

Then Weiwa’s Charcoal Extruder Machine with Cutter or Rod Briquette Machine with Cutter is the ideal solution.

Contactez-nous aujourd'hui pour un consultation gratuite or live demo in Malaysia.

À propos Machinerie Weiwa

ÀMachinerie Weiwa, nous sommes spécialisés danshigh-performance charcoal and briquette machines for global markets, y comprisMalaisie, Asie du Sud-Est, et au-delà. Avecsur 30+ années d'expérience, nous fournissons:

Custom-designed machines (for coconut shell, bois, biomasse).

On-site support & entraînement.

Prix compétitifAvecfast ROI.

Noscutter-integrated charcoal extruders and rod briquette machines are trusted by hundreds of clients worldwide. Let’s discuss how we can optimize your production—get in touch today.

Wechat

Wechat

+8613838093177

+8613838093177