The Rising Demand for Efficient Charcoal Production in India

India’s growing demand for sustainable fuel sources has made charcoal production a booming industry. With abundant bamboo resources, manufacturers are increasingly turning to bamboo sawdust as a raw material for Machines de fabrication de charbon de bois. Cependant, traditional fours à charbon are inefficient, time-consuming, et respectueux de l'environnement. That’s where Weiwa Machinery’s continuous carbonization furnace comes in—a revolutionary solution for continuous carbonization of bamboo sawdust, offrandehigh yield, efficacité énergétique, and eco-friendly operation.

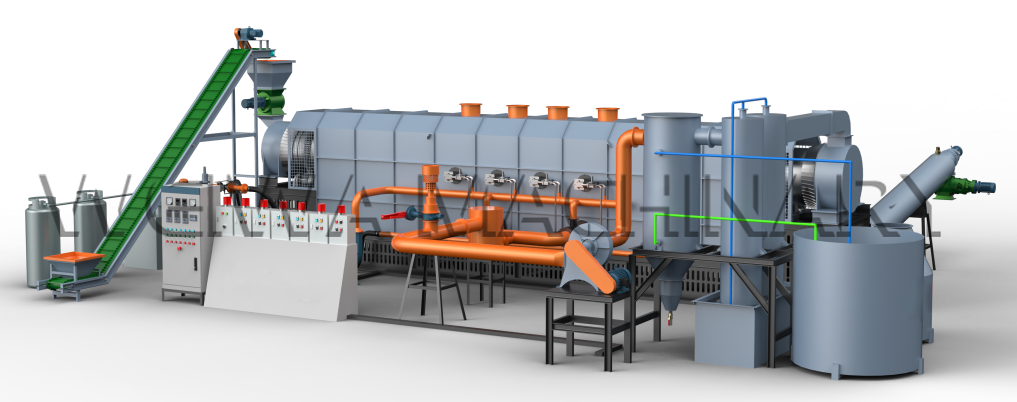

What is a Four à carbonisation continue?

Unfour à carbonisation continue is an advanced machine à fabriquer du charbon de bois that processes biomass (such as bamboo sawdust) into biochar or charcoal in a non-stop, automated manner. Contrairement aux traditionnelsfours à charbon, which require batch processing and long cooling periods, nosfour à carbonisation continue fonctionne 24/7, garantissanthigher productivity and lower energy consumption.

Key Advantages Over Traditional Methods

- Continuous Operation: No need for frequent shutdowns, maximizing output.

- High Carbonization Efficiency: Converts bamboo sawdust into charbon de bois de haute qualité with minimal waste.

- Energy-Saving Design: Recovers and reuses heat, reducing fuel costs.

- Écologique: Émissions faibles, meeting international environmental standards.

For Indian clients, especially those in regions with abundant bamboo waste, this technology is a cost-effective and sustainable alternative to conventional fours à charbon.

Why Bamboo Sawdust Is the Great Raw Material for India?

India is one of the largest producers of bambou, yet much of its biomass goes unused. Bamboo sawdust, a byproduct of woodworking industries, is an ideal raw materialPourcarbonisation because:

- It has a high carbon content, ce qui le rend parfait pourcharcoal production.

- It’s abundant and low-cost, reducing raw material expenses.

- It helps in waste management, turning scrap into valuable fuel.

Noscontinuous carbonization furnace for bamboo sawdust was specifically tested to ensure optimal performance with this material, delivering consistent charcoal qualityAvecminimal impurities.

How Our Continuous Carbonization Furnace Performed?

Récemment, Weiwa Machinery conducted a live trial of our four à carbonisation continue for a client in India, using bamboo sawdust as the primary feedstock. Here’s what we observed:

1. Smooth Startup & Stable Operation

The furnace was installed and operational within a few days, demonstrating its user-friendly design. Lecontinuous feeding system ensured a steady flow of bamboo sawdust without clogging or downtime.

2. Exceptional Carbonization Efficiency

Within hours of operation, the furnace began producing charbon de bois de haute qualité with:

- Carbon content exceeding 85% (ideal for fuel and industrial use).

- Low ash residue (moins que 5%), making the charcoal cleaner and more efficient.

- Uniform heating, ensuring consistent quality throughout the batch.

3. Energy Recovery & Cost Savings

One of the biggest surprises was the heat recovery system, which reused waste gases to preheat incoming raw materials. This reduced fuel consumption by up to 30%, making the process more economical for our Indian client.

4. Minimal Emissions & Conformité environnementale

Contrairement aux traditionnelsfours à charbon, which release harmful smoke, nosfour à carbonisation continue includes a smoke purification system, garantissantclean emissions that meet Indian environmental regulations.

The Future of Continuous Carbonization in India

India’s charcoal market is expanding rapidly, conduit par:

- Demande croissante de carburant respectueux de l'environnement (replacing firewood and coal).

- Government incentives for biomass utilization.

- Export opportunities for high-quality biochar.

Noscontinuous carbonization furnace for bamboo sawdust is perfectly positioned to meet these demands, offering:

Higher productivity than traditional methods.

Coûts opérationnels réduits due to energy efficiency.

Évolutivité—suitable for small workshops to large-scale plants.

AvecIndia’s bamboo resourcesEtincreasing focus on sustainability, the market for continuous carbonization technologyestpoised for exponential growth.

Pourquoi choisir les machines Weiwa?

ÀMachinerie Weiwa, nous sommes spécialisés dansadvanced charcoal making solutions, y compris:

- Fours de carbonisation continue for various biomass materials.

- Conceptions personnalisées to meet specific client needs (like our India-tested bamboo sawdust model).

- End-to-end support, from installation to after-sales service.

NosIndia trial success proves that our technology is fiable, efficace, and tailored for local conditions. We’re committed to helping Indian charcoal producers boost productivity, réduire les coûts, and go green.

A Sustainable, Profitable Solution for Indian Charcoal Producers

Lefour à carbonisation continue is not just a machine—it’s a revolution in charcoal production. For Indian clients, especially those working with bamboo sawdust, this technology offers:

✔Plus rapide, production continue

✔Higher-quality charcoal

✔Lower costs & emissions

✔A competitive edge in the global market

If you’re looking for a trusted partner to upgrade your charcoal production, Machinerie Weiwa is here to help.

Contact Machinerie Weiwa Aujourd'hui

Mobile: +8613838093177

WhatsApp: +8613838093177

E-mail: info@cjlmachinegroup.com

Let’s discuss how our four à carbonisation continue can transform your bamboo sawdust into high-value charcoal—efficiently, sustainably, and profitably.

Wechat

Wechat

+8613838093177

+8613838093177