Introduction: Meeting the Demands of the Middle East Market

The global demand for high-quality shisha charcoal briquettes has surged, en particulier dans des régions comme le Moyen-Orient, où le tabagisme à tuyaux de eau reste un aliment de base culturel. En tant que fabricant de premier plan dans cet espace, Machinerie Weiwa has responded with a state-of-the-art hydraulic press machine designed to produce finer, densiter, and more combustible briquettes—perfectly suited for the arid climate of Saudi Arabia and beyond.

The Challenges of Traditional Charcoal Briquette Production

Inconsistent Density and Combustion Issues

Conventional hydraulic presses often produce briquettes with uneven density, leading to poor burning performance. This is especially problematic in à haute température, low-humidity environments like Saudi Arabia, où les briquettes doivent maintenir une chaleur régulière sans production de cendres excessive.

Limited Adaptability to Harsh Climates

Many machines struggle with dust accumulation, heat dissipation, and material flow in extreme conditions. Weiwa’s upgraded model addresses these pain points with enhanced sealing, cooling systems, and material pathways to ensure consistent output.

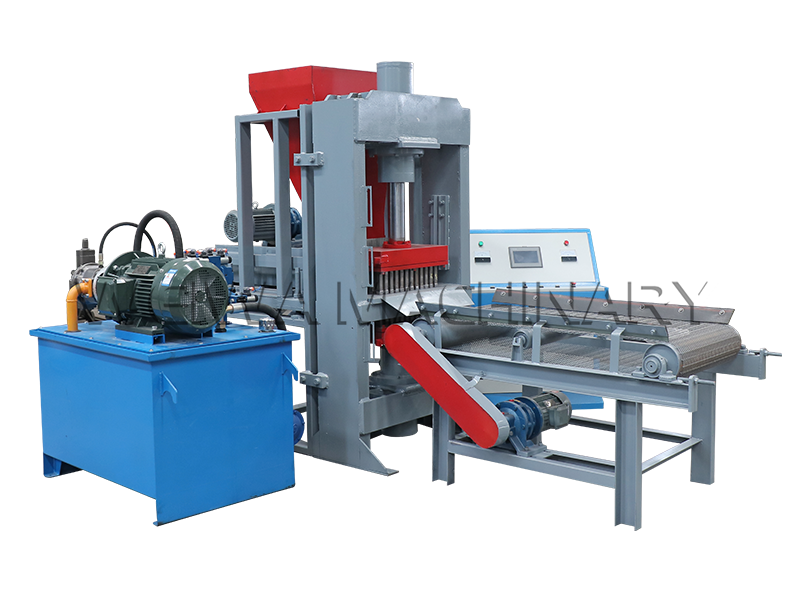

Key Upgrades in Weiwa’s Hydraulic Shisha Charcoal Machine

Finer, More Uniform Briquette Output

Our latest hydraulic press incorporates precision-molded diesEtoptimized pressure control, résultant enbriquettes with tighter compaction. This leads to:

- Temps de combustion plus long (jusqu'à 30% longer than standard briquettes).

- Reduced ash content, enhancing user experience.

- Better heat retention, crucial for shisha sessions.

Enhanced Durability for Middle Eastern Conditions

Saudi Arabia’s dusty, high-temperature environment poses unique challenges. Weiwa’s machine features:

- Reinforced steel frames to withstand sandstorms.

- Advanced cooling systems to prevent overheating.

- Sealed components to minimize dust ingress.

Energy Efficiency and Faster Production

The upgraded hydraulic system reduces cycle time by 15%, while maintaining lower energy consumption compared to older models. This translates to higher output with reduced operational costs.

Field Testing in Saudi Arabia: Real-World Results

Partnering with Local Manufacturers

Weiwa collaborated with a leading shisha charcoal producer in Riyadh to test the machine under real-world conditions. Key findings include:

- Consistent briquette density (measured at 1.4g/cm³, exceeding industry standards).

- Zero clogging or jamming en fonctionnement continu.

- Positive feedback from end-users on burn quality and ash reduction.

Adaptability to Different Raw Materials

The machine was tested with various biomass blends, y compris:

- Coque de coco + sciure (common in the Middle East).

- Olive pits + date pits (sustainable alternatives).

Results showed excellent binding propertiesEtun minimum de déchets.

Why Weiwa’s Hydraulic Press Machine Stands Out

Customizable Design for Diverse Needs

Unlike one-size-fits-all solutions, Offres Weiwa:

- Tailored die sizes to match specific briquette dimensions.

- Paramètres de pression réglables for different material types.

- Modular components for easy maintenance.

Comprehensive After-Sales Support

Nos30+ années d'expérience ensure:

- Installation et formation sur site.

- 24/7 technical supportpour le dépannage.

- Spare parts availability to minimize downtime.

Conclusion: The Future of Shisha Charcoal Production

Weiwa Machinery’s latest hydraulic shisha charcoal briquette machine is a game-changer for manufacturers in the Middle East and beyond. Avec sonsuperior density, combustion efficiency, and climate resilience, it’s the ideal solution for meeting the growing demand for high-quality hookah charcoal.

Ready to Upgrade Your Production?

Contact Weiwa today for a consultation gratuite, customized quotes, and factory visits. Let us help you achieve higher output, lower costs, and unmatched product quality.

À propos Machinerie Weiwa

Avecsur 30 années d'expertise in industrial machinery, Machinerie Weiwase spécialise danshydraulic press machines, machines à briquettes de charbon de bois, and custom manufacturing solutions. Noséquipe après-vente professionnelle, design-to-installation services, etglobal client base make us a trusted partner for businesses worldwide.

Contact us now to request a quote or discuss your project needs—we’re here to help you succeed!

- Whatsapp:+8613838093177

- E-mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177