Au cours des dernières années, the global shift toward sustainable energy has accelerated demand for efficient and eco-friendly fuel alternatives. Parmi ces, charcoal briquettes have emerged as a viable solution—especially in regions with abundant agricultural and forestry waste. Recognizing this trend, Machinerie Weiwa, with over three decades of experience in manufacturing charcoal production equipment, recently conducted an on-site trial of its machine à extrudeuse au charbon de bois in Vietnam. This event not only demonstrated the machine’s capabilities but also highlighted the immense potential of the Vietnamese market for biomass fuel technologies.

The Importance of Charcoal Extrusion Technology in Modern Energy Production

The process of converting raw biomass materials such as sawdust, coccarbures de riz, coquilles de noix de coco, and other agricultural residues into high-density charcoal briquettes involves several stages: écrasement, séchage, carbonizing, and finally, extrusion. The extrusion stage is critical—it determines the shape, densité, and combustion efficiency of the final product. This is where charcoal extruder machines play a pivotal role.

Unlike traditional methods that rely heavily on manual labor or outdated machinery, modern extruders use hydraulic or mechanical pressure systems to compress powdered carbonized material into uniform rods or briquettes. These briquettes burn longer, produce less smoke, and are easier to store and transport—making them ideal for both household and industrial use.

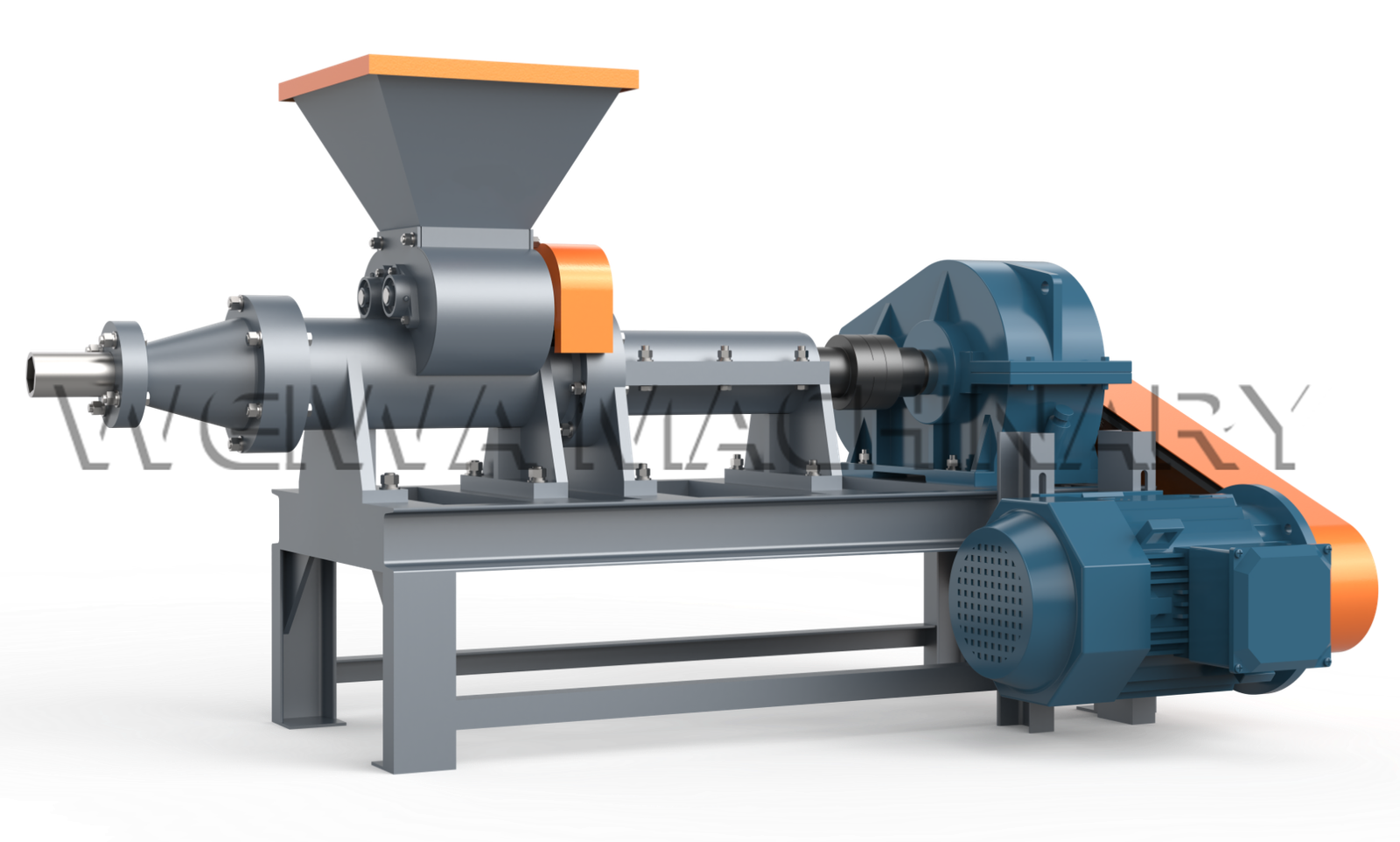

À Weiwa Machinery, our machine à tige de charbon models are designed with precision engineering and robust components to ensure consistent output and minimal downtime. Our machines are capable of processing various types of biomass feedstock, adapting to different moisture levels and particle sizes without compromising quality.

On-Site Trial in Vietnam: Bringing Technology to Life

To showcase the real-world performance of our machine à fabriquer du charbon de bois, we organized a live demonstration at a client’s facility in Ho Chi Minh City, Vietnam. The event was attended by local entrepreneurs, environmental consultants, and government officials interested in promoting clean energy solutions.

Preparing for the Trial

Before the actual test run, our technical team worked closely with the client to assess the availability and suitability of raw materials. Vietnam’s rich agricultural landscape provides an abundant supply of coconut shells and rice husks—two excellent sources of biomass for charcoal production. After conducting preliminary tests on sample materials, we adjusted the machine settings to optimize compression ratios and heating elements based on the specific characteristics of the feedstock.

Le processus du procès

On the day of the trial, the atmosphere was filled with anticipation. Le machine à extrudeuse au charbon de bois, freshly delivered and assembled on-site, stood ready for action. Our engineers loaded the carbonized powder into the hopper, activated the motor, and gradually increased the pressure. Within minutes, dense, cylindrical briquettes began emerging from the die head—each one measuring approximately 30mm in diameter and 100mm in length.

What made this trial particularly impressive was the machine’s ability to maintain consistent output even under varying input conditions. Despite minor fluctuations in material moisture content, the briquettes retained their structural integrity and showed no signs of cracking or deformation. This level of reliability is crucial for commercial operations where production consistency directly impacts profitability.

Capturing the Moment: Video Documentation

To provide transparency and build trust with potential customers, we recorded the entire trial process. The video captures every stage—from material loading to final product inspection—and includes close-up shots of the machine’s operation. Viewers can observe how smoothly the extrusion mechanism functions, hear the low hum of the motor, and see the transformation of loose powder into solid briquettes in real time.

This footage serves as both a marketing tool and an educational resource. For those considering investing in a machine à briquettes de charbon de bois, watching the trial offers valuable insights into what to expect during installation and operation. It also underscores Weiwa Machinery’s commitment to quality and customer satisfaction.

Why Vietnam? Exploring Market Potential for Charcoal Machines?

Vietnam presents a compelling case for investment in charcoal production technology. With a rapidly growing population and increasing urbanization, the country faces rising energy demands. En même temps, environmental concerns have prompted policymakers to seek cleaner alternatives to fossil fuels.

Abundant Biomass Resources

One of Vietnam’s greatest advantages lies in its vast reserves of agricultural and forestry waste. As one of the world’s leading producers of rice, coffee, and cashews, the country generates millions of tons of organic byproducts annually. Much of this waste currently goes unused or is burned openly, contributing to air pollution. By converting these materials into charcoal briquettes, businesses can tap into a renewable resource while reducing environmental harm.

Government Support for Green Energy

The Vietnamese government has implemented several initiatives aimed at promoting renewable energy and reducing greenhouse gas emissions. Incentives such as tax breaks, subsidies, and technical assistance are available for projects that align with national sustainability goals. En plus, international organizations like the World Bank and UNDP have funded programs supporting small-scale biomass enterprises across the country.

These policies create a favorable environment for companies looking to introduce advanced charcoal production technologies. For manufacturers like Weiwa Machinery, partnering with local stakeholders can lead to mutually beneficial outcomes—boosting economic growth while advancing environmental stewardship.

Growing Demand for Clean Cooking Fuels

Despite progress in electrification, many households in rural areas still rely on firewood and charcoal for cooking. Traditional charcoal, often produced through inefficient methods, contributes significantly to deforestation and indoor air pollution. Switching to machine-made briquettes offers a healthier and more sustainable alternative.

De plus, commercial sectors such as restaurants, hotels, and food processing plants are increasingly adopting briquettes due to their cost-effectiveness and ease of handling. As awareness of health and environmental issues grows, so does the demand for high-quality charcoal products—creating new opportunities for producers equipped with modern machinery.

Understanding the Science Behind Charcoal Extrusion

While the concept of compressing biomass into briquettes may seem straightforward, there is considerable science involved in ensuring optimal results. Several factors influence the success of the extrusion process:

Feedstock Preparation

Proper preparation of raw materials is essential. Biomass must be thoroughly dried to reduce moisture content below 15%, as excess water interferes with binding and increases energy consumption during carbonization. Une fois séché, the material is crushed into fine particles (typically less than 3mm) to facilitate uniform mixing and compaction.

Carbonization Techniques

Before extrusion, the biomass undergoes pyrolysis—a thermal decomposition process carried out in the absence of oxygen. This step transforms organic matter into biochar, which possesses higher calorific value and better binding properties. Depending on the scale of operation, carbonization can be performed using drum kilns, continuous retorts, or mobile units.

Die Design and Pressure Control

The design of the extrusion die plays a vital role in determining the shape and density of the final product. Dies come in various configurations, including round, hexagonal, and custom profiles. Adjusting the clearance between the piston and die wall allows operators to control the pressure applied during extrusion, thereby influencing briquette hardness and durability.

Modern machines like those offered by Weiwa Machinery feature adjustable dies and automated pressure regulation systems, enabling precise control over the production process. This flexibility ensures compatibility with diverse feedstocks and end-user requirements.

Overcoming Challenges in Charcoal Production

Although the benefits of charcoal briquettes are clear, establishing a successful production line requires careful planning and execution. Some common challenges include:

Equipment Selection

Choosing the right machine à extrudeuse au charbon de bois depends on factors such as production capacity, feedstock type, and budget constraints. Smaller operations may opt for single-screw extruders, while larger facilities typically require double-screw models for higher throughput. Weiwa Machinery offers a range of options tailored to different scales of operation, backed by decades of engineering expertise.

Maintenance and Downtime

Like any mechanical system, extruders require regular maintenance to function efficiently. Worn-out parts, clogged dies, and electrical faults can disrupt production schedules and increase operational costs. To address this, Weiwa Machinery provides comprehensive after-sales support, including spare parts supply, remote troubleshooting, and on-site training for technicians.

Quality Assurance

Maintaining consistent briquette quality is essential for building customer loyalty and meeting regulatory standards. Variations in raw material composition, humidity levels, and machine settings can affect product performance. Implementing strict quality control measures—such as periodic sampling, density testing, and combustion analysis—helps ensure compliance with industry benchmarks.

Customer Success Stories from Around the Globe

Weiwa Machinery’s journey spans continents, with successful installations in countries ranging from Indonesia to Nigeria. One notable example comes from Cambodia, where a local entrepreneur invested in a complete charcoal production line featuring our machine à tige de charbon. Within six months of operation, the business expanded its customer base to include supermarkets, restaurants, and export markets.

Another success story originates from Brazil, where a cooperative of smallholder farmers adopted our technology to convert coffee husks into premium-grade briquettes. Not only did this initiative generate additional income streams for participants, but it also reduced reliance on unsustainable firewood harvesting practices.

These examples illustrate the transformative impact of modern charcoal extrusion technology when paired with strategic planning and community engagement. They also reinforce our belief that innovation, combined with local knowledge, holds the key to unlocking the full potential of biomass resources.

Looking Ahead: Trends Shaping the Future of Charcoal Production

As global awareness of climate change intensifies, the charcoal industry is poised for significant evolution. Several trends are likely to shape its trajectory in the coming years:

Automation and Smart Manufacturing

Advancements in IoT (Internet of Things) and AI (Artificial Intelligence) are revolutionizing manufacturing processes across industries. In the context of charcoal production, smart sensors and predictive analytics can monitor equipment performance, detect anomalies, and optimize energy usage. Automated feeding systems and robotic palletizers further enhance efficiency and reduce labor dependency.

Weiwa Machinery is actively exploring ways to integrate digital technologies into our product offerings, paving the way for Industry 4.0-compliant solutions.

Circular Economy Models

The concept of circular economy emphasizes resource efficiency and waste minimization. In practice, this means designing systems where outputs become inputs for other processes. Par exemple, ash generated during briquette combustion can be repurposed as fertilizer or construction material. Similarly, wastewater from carbonization units can be treated and reused within the facility.

By embracing circular principles, producers can lower their environmental footprint while creating additional revenue streams.

Certification and Traceability

Consumers are becoming increasingly conscious of product origins and sustainability credentials. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management Systems) lend credibility to charcoal brands and open doors to premium markets. Blockchain technology offers a promising avenue for tracking supply chains and verifying compliance with ethical standards.

Weiwa Machinery supports clients in obtaining relevant certifications by providing documentation, entraînement, and guidance throughout the accreditation process.

Why Choose Machinerie Weiwa?

Avec plus 30 years of experience in the field of charcoal production equipment, Weiwa Machinery has established itself as a trusted name in the industry. Our commitment to excellence is reflected in every aspect of our business—from product design and manufacturing to customer service and technical support.

Professional After-Sales Team

Our dedicated after-sales team consists of highly trained engineers and technicians who provide prompt assistance whenever needed. Whether it’s troubleshooting technical issues, scheduling routine maintenance, or delivering replacement parts, we go above and beyond to ensure uninterrupted operations for our clients.

Solutions personnalisées

No two projects are alike. That’s why we offer customized solutions tailored to each client’s unique needs. From selecting the appropriate machine model to designing layout plans for factory setups, our experts work closely with customers to deliver turnkey solutions that maximize efficiency and profitability.

Comprehensive Training Programs

Operating complex machinery requires specialized skills. To empower our clients, we conduct hands-on training sessions covering all aspects of machine operation, entretien, and safety protocols. Participants gain practical experience under the guidance of seasoned professionals, equipping them with the knowledge needed to succeed in their ventures.

Conclusion

The trial of our machine à extrudeuse au charbon de bois in Vietnam marked a significant milestone in our mission to promote sustainable energy solutions worldwide. Through live demonstrations, video documentation, and collaborative engagement, we showcased the power of innovation in transforming biomass waste into valuable commodities.

Vietnam’s abundant natural resources, supportive policy framework, and growing demand for clean fuels make it an ideal destination for charcoal production investments. Companies seeking to capitalize on this opportunity should look no further than Weiwa Machinery—a reliable partner with a proven track record of delivering cutting-edge technology and exceptional service.

If you’re interested in learning more about our products or would like to schedule a consultation, visit our website at https://cjljx.com/product/charcoal-extrude-machine. Let us help you turn your vision into reality.

- Foule:+8613838093177

- Whatsapp:+8613838093177

- E-mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177