Introduction to Charcoal Briquette Machines

Charcoal briquette machines, tel que extrudeuses de charbon de bois, sont essentiels pour convertir la biomasse des déchets ou la poussière de charbon en tiges de combustible à haute densité. These machines are widely used in Uganda for domestic and industrial applications due to their cost-effectiveness and environmental benefits.

ÀMachinerie Weiwa, we specialize in manufacturing high-performance charcoal extruder machines, machines d'extrudeuse de sciure de bois, et machines à briquettes à billes designed for efficiency and durability. In this blog, we’ll explore the working principles of these machines and share insights from a recent test run of our equipment.

How Does a Charcoal Extruder Machine Work?

Key Components & Process

Unmachine à extrudeuse au charbon de bois compresses raw materials (poudre de charbon de bois, poussière de charbon, or biomass) under high pressure, forcing them through a mold to form solid briquettes. Le processus implique:

- Feeding System: Raw materials are fed into the machine’s hopper.

- Compression & Extrusion: A screw conveyor pushes the material into a compression chamber, where high pressure forms dense rods.

- Cutting & Séchage: The extruded rods are cut to size and dried for optimal combustion.

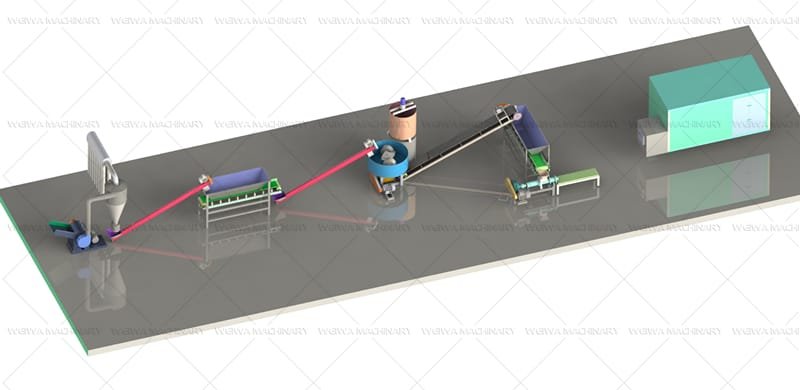

We can also customize the ligne de production according to the customers’ exigences.

Why Choose a Rod Briquette Machine?

Rod-shaped briquettes offer several advantages:

- Higher density for longer burning time.

- Lower smoke emissions compared to loose charcoal.

- Easier storage & transport due to uniform shape.

Weiwa’s Charcoal Extruder Test Run: Principales conclusions

Test Setup & Parameters

We conducted a real-world test run of our machine à extrudeuse au charbon de bois under typical Ugandan operating conditions. The test focused on:

- Production capacity (kg/heure)

- Energy efficiency (power consumption)

- Qualité des briquettes (densité, durabilité, et le temps de brûlure)

Performance Results

Our machine demonstrated:

- Efficacité de production élevée, producing 500-1000 kg/heure depending on material moisture.

- Low power consumption, making it cost-effective for small and medium businesses.

- Consistent briquette quality, with dense, crack-free rods ideal for cooking and industrial use.

Factors Affecting Charcoal Extruder Machine Price in Uganda

When evaluating charcoal making machine prices, consider:

- Machine capacity (small-scale vs. industrial models).

- Material compatibility (poussière de charbon de bois, sciure, ou déchets agricoles).

- After-sales support, including installation and maintenance.

Offres de machines Weiwacompetitive pricing sans compromettre la qualité, ensuring a strong return on investment for Ugandan customers.

Why Choose Machinerie Weiwa?

Avecsur 30 années d'expérience, Weiwa Machinery is a trusted name in briquette machine manufacturing. Nosexpert technical team provides:

- Solutions personnalisées tailored to your production needs.

- On-site installation & entraînement for smooth operation.

- Reliable after-sales support, including spare parts and troubleshooting.

Que vous ayez besoin d'unmachine à extrudeuse au charbon de bois, Presse de briquette de tige, or full production line, Weiwa delivers durable, équipement performant at a fair price.

Contactez-nous

WhatsApp/WeChat/Tel:+86 13838093177

E-mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177