Introduction: The Rising Demand for Charcoal Briquettes

Au cours des dernières années, the global demand for briquettes de charbon de boisa explosé, driven by their applications in Barbecues, chauffage industriel, et des alternatives de carburant respectueuses de l'environnement. En tant que fabricant leader, Machinerie Weiwase spécialise dansball charcoal briquette machines, lignes de production, and complete plants that transform raw materials into high-density briquettes efficiently.

Understanding Charcoal Briquette Machines: Types & Functions

What is a Ball Charcoal Briquette Machine?

Unmachine à briquette à charbon de bois à balle is a specialized press that compresses poussière de charbon de bois, biomasse, or coal fines into uniform ball-shaped briquettes. These machines are crucial for producing de haute qualité, long-burning briquettes avec des exigences minimales en matière de liant.

Offres de machines Weiwacustomizable ball briquette machines that adjust to different raw materials and production scales, garantissanthaute densité et durabilité.

Types of Charcoal Briquette Machines

While machines à briquettes à billes are popular for their uniform shape, other variants include:

Each type serves different markets, maisball briquettes remain a top choice due to their clean burn and easy handling.

How a Ball Charcoal Briquette Production Line Works

Step-by-Step Production Process

https://youtu.be/qkZE9rijtKA

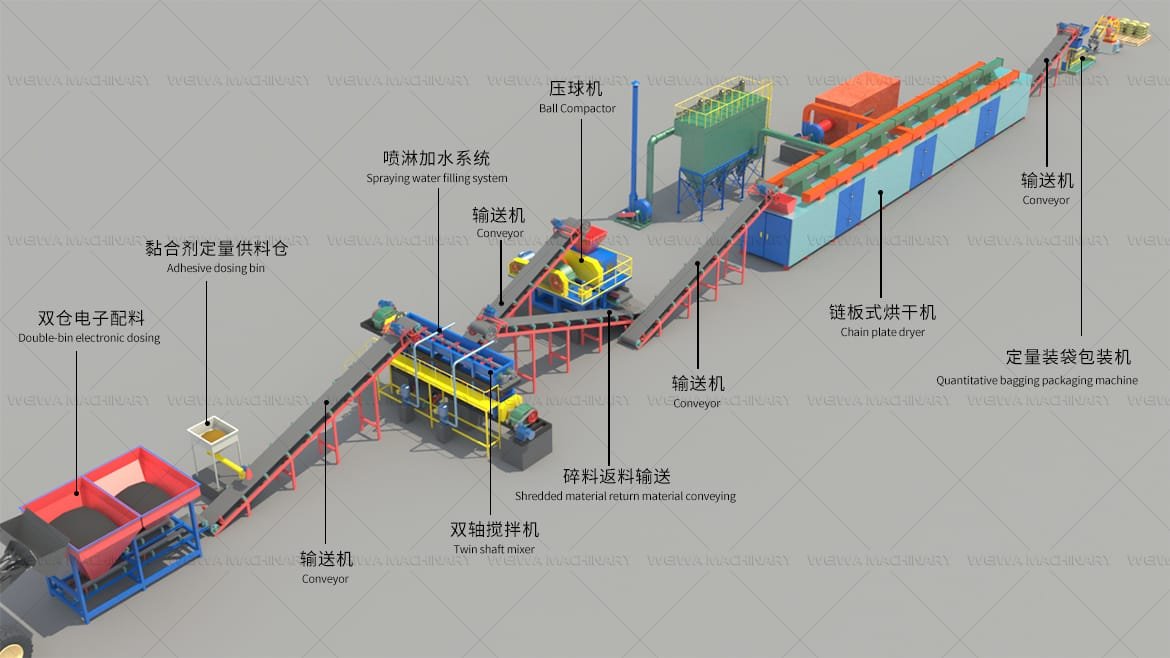

Uncomplete charcoal briquette machine product line includes:

- Préparation des matières premières – Crushing and drying charcoal dust or biomass to the right moisture level (~8-12%).

- Briquette – Feeding the material into the machine à briquette à charbon de bois à balle, which compresses it into dense balls.

- Séchage – Using a rotary dryer or natural sun drying to harden the briquettes for storage.

- Conditionnement & Distribution – Ready for sale in BBQ markets, industrial clients, or export.

Celui de Weiwaproduction line is designed for efficiency, reducing waste and maximizing output.

Potentiel de marché: Why Invest in a Charcoal Briquette Business?

Demande mondiale croissante

- Barbecue & Outdoor Cooking: Consumers prefer nettoyeur, smokeless briquettes over traditional lump charcoal.

- Industrial Fuel: Foundries, ceramics, and food processing industries use briquettes as a cost-effective alternative to coal.

- Eco-Friendly Trends: Governments promote briquettes de biomasse to reduce deforestation and carbon emissions.

Profitability Insights

- Low raw material cost (poussière de charbon de bois, sciure, déchets agricoles)

- High demand in domestic & international markets

- Scalable production (small workshops to large plants)

Weiwa Machinery helps clients design customized production lines based on their budget and target market.

Why Choose Weiwa Machinery for Your Briquette Line?

30+ Years of Expertise

Avecover three decades in the industry, Weiwa has refined its ball charcoal briquette machinesPourdurabilité, efficacité, and high output.

Solutions personnalisées & Professional Support

- Design drawings & site planning tailored to your facility

- Équipe après-vente professionnelle for installation and troubleshooting

- OEM/ODM services for unique client requirements

Competitive Advantage

- Energy-efficient machines reducing operational costs

- High briquette density & low breakage rate

- Global export experience (Afrique, Asie du Sud-Est, Europe, etc.)

Start Your Charcoal Briquette Business with Weiwa

Leball charcoal briquette machine market is booming, and with the right equipment, your business can thrive. Que vous ayez besoin d'unsmall-scale production line or a full-scale plant, Machinerie Weiwa provides fiable, high-performance machinery backed by expert support.

Contact us today for a free consultation, custom quotes, and factory layout planning!

- Foule:+8613838093177

- Whatsapp:+8613838093177

- E-mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177