In today’s global push toward sustainable energy and eco-friendly fuel alternatives, the role of efficient and reliable machinery becomes paramount. À Weiwa Machinery, we take pride in engineering state-of-the-art equipment that meets diverse industrial needs across continents. Récemment, we had the privilege of hosting a valued client from Bhutan for an exclusive video factory tour. The focus was our flagship Honeycomb briquette charcoal machine and its related technologies.

Understanding the Significance of Honeycomb Briquette Charcoal Machines

The demand for alternative fuels has grown exponentially due to deforestation, rising LPG prices, and the environmental toll of traditional coal use. In this context, the honeycomb briquette charcoal machine emerges as a beacon of innovation. These machines transform fine coal dust or charcoal powder into solid, easy-to-use briquettes shaped like a honeycomb — optimizing combustion while minimizing waste.

À Weiwa Machinery, our honeycomb briquette charcoal machine is designed not only for performance but also for adaptability to various raw materials such as anthracite, bituminous coal, lignite, and even biomass charcoal. Its structure supports small and medium enterprises aiming to produce clean-burning fuel briquettes for household and commercial purposes.

What Makes a Honeycomb Briquette Unique?

Unlike conventional solid coal blocks, honeycomb briquettes contain multiple holes through their cross-section, resembling a beehive. This design increases the surface area, allowing oxygen to flow more freely during combustion. Par conséquent, users benefit from reduced smoke, minimized harmful emissions, and better heat control. It’s a preferred choice in regions where indoor cooking remains prevalent and air quality is a concern.

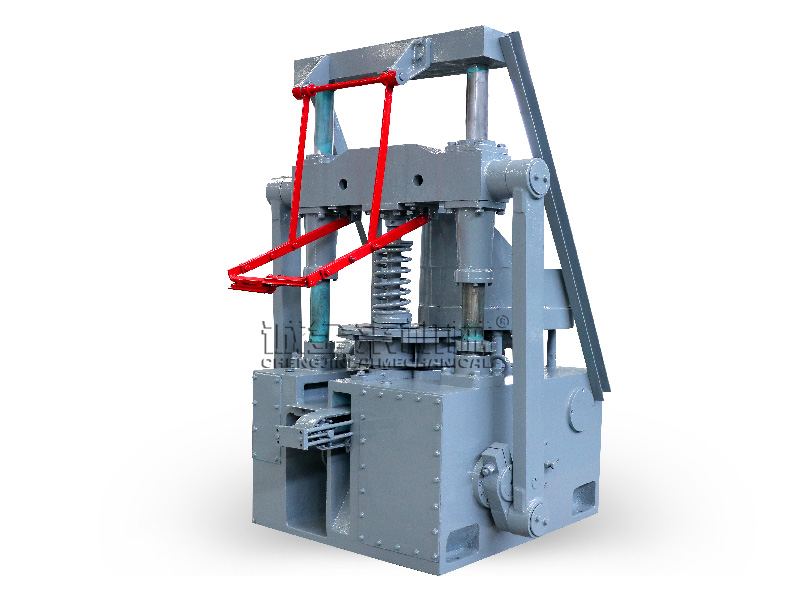

Our honeycomb charcoal coal briquette forming machine achieves this precise shape using a combination of high hydraulic pressure and mechanical punching systems. The final product is compact, sturdy, and highly efficient in burning, making it ideal for both rural kitchens and urban industries seeking greener solutions.

The Technology Behind the Honeycomb Punching Machine

Central to our manufacturing line is the honeycomb punching machine, a core component of the entire briquetting process. This unit performs the critical task of shaping the coal powder mixture into briquettes by driving it through a die with pre-designed hole patterns.

Weiwa Machinery integrates intelligent control systems into our honeycomb punching machine to ensure consistency in size, densité, and shape. Each punch cycle is optimized to reduce material loss and maximize throughput. The hydraulic system operates at adjustable pressures, which means clients can tailor output based on specific material characteristics and desired briquette hardness.

De plus, the durability of our machine parts ensures minimal downtime. We utilize alloy steel for punches and dies, which resist wear even under high-volume production. For our Bhutan client, we highlighted how these features translate into long-term cost savings and reliability in mountainous terrains where maintenance access may pose logistical challenges.

Live Demonstration During the Bhutan Client Video Tour

Understanding that seeing is believing, we arranged a real-time video walkthrough tailored for our client based in Bhutan. The session was hosted by our senior engineer and overseen by our international sales director to provide technical depth and business clarity.

Welcoming the Client to Our Manufacturing Base

We began the tour with a panoramic view of our facility, showcasing rows of finished honeycomb briquette charcoal machines ready for shipment. Our guide explained the layout of the assembly lines, quality testing stations, and packaging units. Special emphasis was placed on how we maintain stringent ISO-certified protocols throughout production.

For our Bhutan client, we underlined our commitment to exporting machines suited to varied voltage standards and climatic conditions. Given Bhutan’s hilly geography and distinct seasons, ensuring equipment resilience is vital.

Step by Step: From Raw Material to Finished Briquette

During the live demo, we fed a prepared mixture of powdered charcoal and binder into the hopper of the honeycomb briquette charcoal machine. Viewers observed the conveyor system transporting the material to the compression chamber. With precision timing, the honeycomb punching machine activated, exerting pressure to form briquettes that were ejected onto a collection tray.

Each briquette displayed uniform shape and structural integrity. Our engineer elaborated on how moisture content and particle size influence briquette strength, sharing tips that are especially useful for new entrepreneurs entering the market.

We also demonstrated the ease of mold replacement, allowing production of different diameters and hole configurations. This flexibility positions our coal briquettes making machine as a versatile investment for growing businesses.

Testing Combustion Efficiency On-Site

To further impress upon the practical advantages, we conducted a mini combustion test. Two samples — one standard lump coal and one honeycomb briquette — were burned side by side. Observers noted that the honeycomb briquette produced significantly less smoke, sustained fire longer, and generated higher thermal efficiency.

This visual proof resonated well with our Bhutan client, who expressed interest in promoting cleaner cooking methods among local communities. We discussed potential subsidies and partnerships with regional agencies focusing on sustainable development.

Customization and Support for International Clients

One highlight of the session was addressing customization options available for our honeycomb charcoal coal briquette forming machine. While our standard models serve a broad range of applications, we recognize that some markets require tailored solutions.

Par exemple, clients operating in colder climates might need faster heating cycles, whereas others may prioritize portability. We shared case studies of similar adaptations made for clients in Nepal and Mongolia, drawing parallels to Bhutan’s unique requirements.

Beyond machinery, Weiwa Machinery provides comprehensive support packages including installation guidance, remote troubleshooting, operator training, and access to spare parts. Our after-sales team is fluent in English and several Asian languages, ensuring smooth communication across borders.

Environmental and Economic Impacts in Focus

Throughout the demonstration, we emphasized the dual benefits of adopting honeycomb briquette technology — environmental preservation and economic empowerment. By converting waste coal fines and biomass residues into valuable fuel, industries can reduce landfill dependency and curb pollution.

Local economies also gain through job creation in briquette production units and distribution networks. Women-led self-help groups in South Asia have successfully utilized our coal briquettes making machine to launch micro-enterprises, improving household incomes and social standing.

For Bhutan, a nation striving to balance modernization with ecological conservation, integrating such machinery aligns perfectly with national goals. Our client showed keen interest in piloting community-based projects that could leverage our technology for wider outreach.

Why Choose Weiwa Machinery for Your Briquetting Needs?

As the tour concluded, we revisited why Weiwa Machinery stands out in a competitive landscape. Our relentless focus on R&D enables us to stay ahead with energy-efficient designs and user-centric enhancements. Every honeycomb briquette charcoal machine leaving our factory embodies years of refinement and field feedback from over 30 pays.

Clients choose us not just for machines but for trust. Transparency in pricing, ethical manufacturing practices, and responsive customer care define our brand promise. We don’t merely sell equipment — we build partnerships aimed at lasting impact.

Sample Showcase: Highlighted Models for Bhutan Market

Although the video tour primarily featured our general-purpose models, we introduced two variants specifically relevant for Bhutan’s scale and scope:

The WW-HBC120 is a compact honeycomb briquette charcoal machine ideal for startups. It delivers up to 120 briquettes per minute with low power consumption, suitable for intermittent operation in rural settings.

The WW-HBC300, meanwhile, caters to larger enterprises. Engineered for continuous duty, it boasts triple punching heads and automated feeding, capable of producing over 300 briquettes per minute without compromising on finish quality.

Both models can be equipped with optional electric or diesel power systems, providing flexibility for areas with unstable grid connectivity.

Closing Thoughts on the Bhutan Collaboration

Hosting our client from Bhutan was a rewarding experience that allowed us to share our passion for sustainable fuel solutions. The interactive format of the video tour broke geographical barriers and built trust through transparency. It reaffirmed our belief that technology, when paired with empathy and understanding, can drive meaningful change.

We extend our gratitude to our Bhutan partner for their curiosity and engagement. We look forward to supporting their journey toward cleaner energy and economic growth with our reliable honeycomb punching machine and associated systems.

À propos Machinerie Weiwa

Weiwa Machinery is a leading manufacturer and exporter of briquetting equipment headquartered in China. With decades of specialization in coal briquettes making machines and allied technologies, we serve clients in over 40 pays. Our product lineup includes honeycomb briquette charcoal machines, honeycomb charcoal coal briquette forming machines, and custom-engineered punching systems. Driven by innovation and committed to sustainability, Weiwa Machinery strives to empower industries worldwide with efficient, eco-conscious solutions. Whether you are a small startup or an expanding enterprise, we are ready to collaborate in shaping a greener future.

Wechat

Wechat

+8613838093177

+8613838093177