Introduction

ÀMachinerie Weiwa, we are thrilled to announce the successful shipment of our state-of-the-art four à carbonisation continue to Indonesia. This milestone marks a significant step in our mission to provide sustainable and efficient charcoal-making solutions to global markets, particularly in Indonesia, where biomass resources are abundant and the demand for high-quality charcoal is ever-growing.

What is a Four à carbonisation continue?

Understanding the Technology

Unfour à carbonisation continue is an advanced thermal processing system designed to convert biomass materials into charcoal through a controlled, high-temperature carbonization process. Contrairement aux méthodes traditionnelles de carbonisation par lots, nossystème continu operates non-stop, allowing for uninterrupted feeding and discharging of raw materials.

Our furnace utilizes a double-cylinder rotary design, featuring an inner drum for drying and an outer drum for carbonization. Biomass feedstocks such as coquilles de noix de coco, paille, sciure, coccarbures de riz, et copeaux de bois are spiraled through the furnace, garantissantuniform temperature control (typically around 500–600 °C) and consistent charcoal quality.

Key Features and Benefits

- Self-Sustaining Heat Cycles: En récupérant et en rebrûlant les gaz combustibles (CO, CH₄, H₂), our system achieves efficacité énergétique and minimizes external fuel requirements.

- Grande efficacité & Capacité: Designed for large-scale production, the continuous furnace supports 24/7 automated operations, making it ideal for industrial applications.

- Emission Reduction: The recovery and reuse of gases significantly cut down emissions, aligning with global sustainability goals.

- Versatilité: Suitable for a wide range of biomass materials, ensuring adaptability to different regional feedstocks.

Shipment to Indonesia

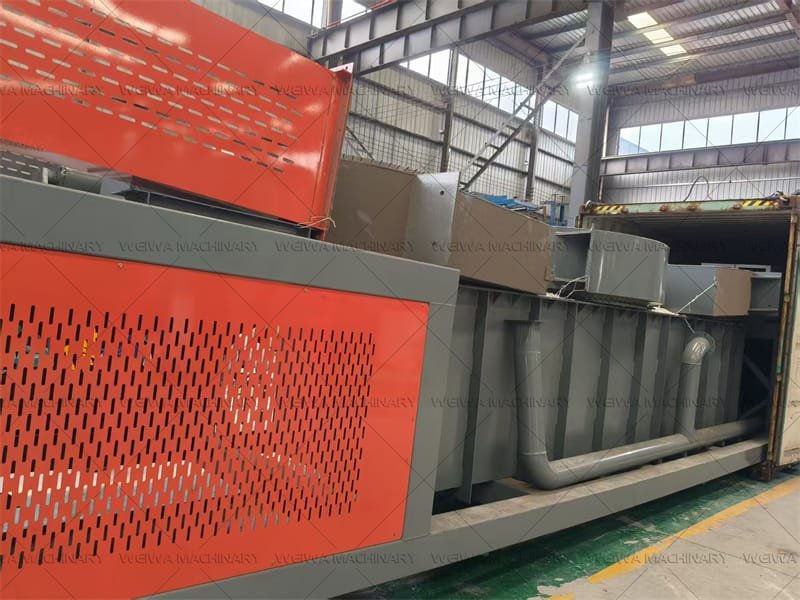

Preparing for Export

The journey of our continuous carbonization furnace to Indonesia began with meticulous planning and coordination. Our team at Weiwa Machinery worked closely with the Indonesian client to understand their specific requirements, ensuring the furnace was customized for optimal performance in their operational environment.

From quality inspections to safety packaging, every step was executed with precision. The furnace components were carefully disassembled, emballé, and loaded onto shipping containers to withstand the rigors of international transit.

Le voyage commence

The shipment departed from our manufacturing facility in China, destined for Indonesia. Our logistics team ensured timely customs clearance and smooth transportation to the client’s site.

This shipment is not just a delivery of machinery; it represents Weiwa Machinery’s commitment to delivering innovative solutions and fostering long-term partnerships in the global market.

Trial Run Results Proving Performance

On-Site Installation and Testing

Upon arrival in Indonesia, our technical team traveled to the client’s location to oversee the installation and commissioning du four de carbonisation continue. The setup process was streamlined, thanks to our comprehensive installation and maintenance guides, as well as the on-site support provided by our field service technicians.

Letrial run was conducted using local biomass feedstocks, y compriscoconut shells and wood chips, which are abundantly available in Indonesia.

Impressive Outcomes

The results of the trial run exceeded expectations:

- High Charcoal Yield: The furnace achieved a remarkable charcoal yield, demonstrating its efficiency in converting biomass into high-quality charcoal.

- Qualité constante: The produced charcoal exhibited uniform properties, meeting the client’s specifications for various applications, including industrial use and household fuel.

- Efficacité énergétique: The self-sustaining heat cycles significantly reduced the need for external fuel, résultant enlower operational costs.

- Emission Control: The system effectively managed emissions, aligning with Indonesia’s environmental regulations and sustainability goals.

The client was highly satisfied with the performance, marking a successful start to our collaboration.

Continuous Carbonization Furnace in Indonesia

Why Indonesia?

Indonesia is a prime market for our continuous carbonization furnace, thanks to its ressources de biomasse abondantes and growing demand for charcoal. The country is one of the world’s largest producers of coquilles de noix de coco, coquilles de noyau de palmier, and wood residues, making it an ideal location for biomass-to-charcoal conversion.

En plus, the Indonesian government is actively promoting renewable energy and sustainable practices, creating a favorable environment for technologies like our continuous carbonization furnace.

Applications and Benefits for Indonesian Clients

- Industrial Use: The high-quality charcoal produced by our furnace is suitable for metallurgical, chemical, and manufacturing industries.

- Household Fuel: The charcoal can be used as a clean and efficient cooking fuel, reducing reliance on traditional firewood.

- Waste Management: By converting agricultural and forestry residues into valuable charcoal, our furnace helps address waste management challenges in Indonesia.

Continuous Carbonization Furnace Price

One of the most frequently asked questions is about the continuous carbonization furnace price. À Weiwa Machinery, Nous offronscompetitive pricing without compromising on quality or performance.

Our pricing model is designed to provide value for money, considering factors such as:

- Customization: Tailored solutions to meet specific client requirements.

- Assistance après-vente: Comprehensive services, y comprisinstallation, entretien, et formation en fonctionnalité.

- Long-Term Savings: Energy efficiency and reduced operational costs ensure a high return on investment.

For clients in Indonesia and beyond, our continuous carbonization furnace represents a smart and sustainable investment.

Partnering for a Sustainable Future

The shipment of our continuous carbonization furnace to Indonesia is a testament to Weiwa Machinery’s dedication to innovation, qualité, and global collaboration.

As we continue to expand our presence in international markets, we remain committed to providing cutting-edge solutions that address the evolving needs of our clients. The success of this shipment reinforces our position as a trusted partner in the biomass-to-charcoal industry.

We invite potential clients in Indonesia and other regions to explore our continuous carbonization furnace and discover how it can transform your operations.

À propos Machinerie Weiwa

ÀMachinerie Weiwa, we specialize in the design and manufacture of advanced biomass processing equipment, y comprisbriquette machines, fours de carbonisation, et machines associées. With over 2 million satisfied customers worldwide, we have established ourselves as a leader in the industry.

Notre mission est de fournirdurable, efficace, et des solutions rentables that empower our clients to achieve their production goals while minimizing environmental impact.

Contactez-nous aujourd'hui pour en savoir plus sur nos produits et services. Our team is ready to assist you with Solutions personnalisées, installation support, and training.

- E-mail: info@cjlmachinegroup.com

- Téléphone / WhatsApp: +8613838093177

- Wechat: +86 13838093177

- Adresse: Route Huangshan, Route zijing, Gongyi, Zhengzhou, Henan

Let’s work together to build a greener future.

Wechat

Wechat

+8613838093177

+8613838093177