The Rising Demand for Charcoal Balls in Myanmar

Myanmar’s growing demand for solutions de carburant durables has made boules de charbon de bois an increasingly popular choice for households, restaurants, et applications industrielles. As traditional charcoal production faces environmental and efficiency challenges, mechanized charcoal ball production—powered by ball charcoal briquettes machines—is emerging as a game-changer.

ÀMachinerie Weiwa, we specialize in providing high-performance charcoal ball press machinesEtcomplete briquette production lines tailored for the Myanmar market. With over 30 années d'expertise, our machines ensure high yield, faible consommation d'énergie, and consistent quality, making us a trusted partner for charcoal producers across Southeast Asia.

How Ball Charcoal Briquette Machines Work?

What is a Charcoal Ball Press Machine?

Unpresse à boules de charbon de bois (also called a machine à briquettes de charbon de bois) is a mechanical device that compresses poudre de charbon de bois, biomass residues, or coal dust dans solid, uniform charcoal balls. These machines eliminate the need for binders in many cases, relying on high pressure and frictional heat to form durable briquettes.

Celui de Weiwamachines à briquettes de charbon de bois are engineered for:

- High compression efficiency (ensuring minimal waste)

- Construction durable (suitable for continuous operation)

- Adjustable molds (for different ball sizes)

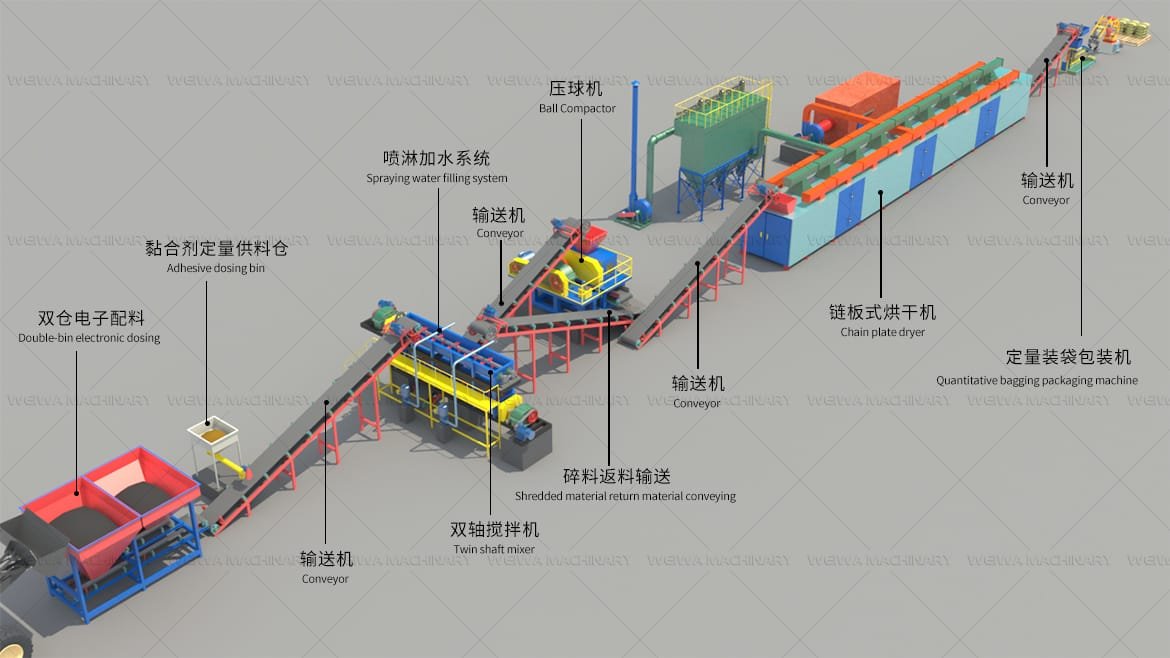

The Role of a Charcoal Briquette Machine Line

Uncomplete charcoal briquette production line includes:

- Concassage de matières premières & Grinding (to produce fine charcoal powder)

- Mélange & Séchage (to achieve optimal moisture content)

- Briquette (Pressing) (using our presse à boules de charbon de bois)

- Séchage & Conditionnement (to ensure long shelf life)

Weiwa fournit end-to-end solutions, ensuring smooth operations from raw material intake to finished charcoal balls.

Why Myanmar is a Prime Market for Charcoal Ball Production?

1. Growing Demand for Clean & Efficient Fuel

Myanmar’s households and small businesses rely heavily on bois de chauffage et charbon de bois traditionnel, qui sontinefficient and environmentally damaging. Boules de charbon offer:

- Higher calorific value (burning longer and cleaner)

- Émissions de fumée réduites (better for health & air quality)

- Convenient storage & transport (compared to loose charcoal)

2. Abundant Biomass Resources

Myanmar has vast agricultural and forestry residues (coccarbures de riz, sciure, coquilles de noix de coco), which can be converted into charcoal powder for briquetting. Nosball charcoal briquettes machines efficiently process these materials into profitable charcoal balls.

3. Potentiel d'exportation & Industrial Applications

Beyond domestic use, Myanmar-produced charcoal balls have export potential to neighboring countries. En plus, industries like métallurgie, transformation des aliments, et céramique use charcoal briquettes for high-temperature applications.

How Weiwa’s Charcoal Ball Press Machine Benefits Myanmar Producers?

1. Grande efficacité & Low Operating Costs

Nosmachines à briquettes de charbon de bois are designed to maximiser le rendement tout en minimisant la consommation d’énergie, reducing production costs for Myanmar businesses.

2. Durable & Low-Maintenance Design

Built with high-grade steel and wear-resistant components, Weiwa’s machines ensure long lifespan and minimal downtime, even in demanding production environments.

3. Customizable Solutions for Local Needs

We understand that Myanmar’s raw materials and production scales vary. That’s why Weiwa offers:

- Different press capacities (small, medium, large-scale)

- Custom mold designs (for varying charcoal ball sizes)

- On-site installation & entraînement (ensuring smooth operations)

4. Reliable After-Sales Support

Noséquipe après-vente professionnelle provides:

- Technical guidance

- Spare parts availability

- Remote troubleshooting

Successful Charcoal Ball Production in Myanmar with Weiwa

UnMyanmar-based charcoal producer was struggling with low efficiency and inconsistent charcoal ball quality. After partnering with Machinerie Weiwa, they installed a complete charcoal briquette production line, y compris:

- Écrasement & drying equipment

- Weiwa’s high-pressure ball charcoal briquettes machine

- Automated drying system

Résultats:

30% Augmentation de l'efficacité de la production

Higher-quality charcoal balls with better market demand

Faster ROI within 6 months

This success story highlights how Weiwa’s Solutions personnalisées help Myanmar businesses scale profitably.

Partner with Weiwa for Your Myanmar Charcoal Ball Production Needs

Myanmar’s charcoal industry is evolving, etmechanized production using ball charcoal briquettes machines is the future. AvecWeiwa Machinery’s expertise, durable equipment, et solutions personnalisées, your business can:

✔Produce high-quality charcoal balls efficiently

✔Reduce costs and environmental impact

✔Tap into local and export markets

En tant quetrusted manufacturer with 30+ années d'expérience, Weiwa fournit not just machines—but a complete partnership. Nosprofessional team ensures smooth installation, entraînement, and ongoing support to maximize your success.

Contact Weiwa Machinery today for a quote or consultation on setting up your charcoal ball production line in Myanmar.

À propos Machinerie Weiwa

Avecsur 30 années d'expérience dans la fabrication briquette and pellet machines, Machinerie Weiwa is a leading supplier of presses à billes de charbon de boisEtlignes de production complètes. We serve clients globally, offering:

- Customized machine designs & layout planning

- Service après-vente professionnel & technical support

- Reliable spare parts supply

Let us help you turn raw materials into profitable charcoal balls—contact us today for a free consultation or inquiry.

- Foule:+8613838093177

- Whatsapp:+8613838093177

- E-mail:info@cjlmachinegroup.com

Wechat

Wechat

+8613838093177

+8613838093177