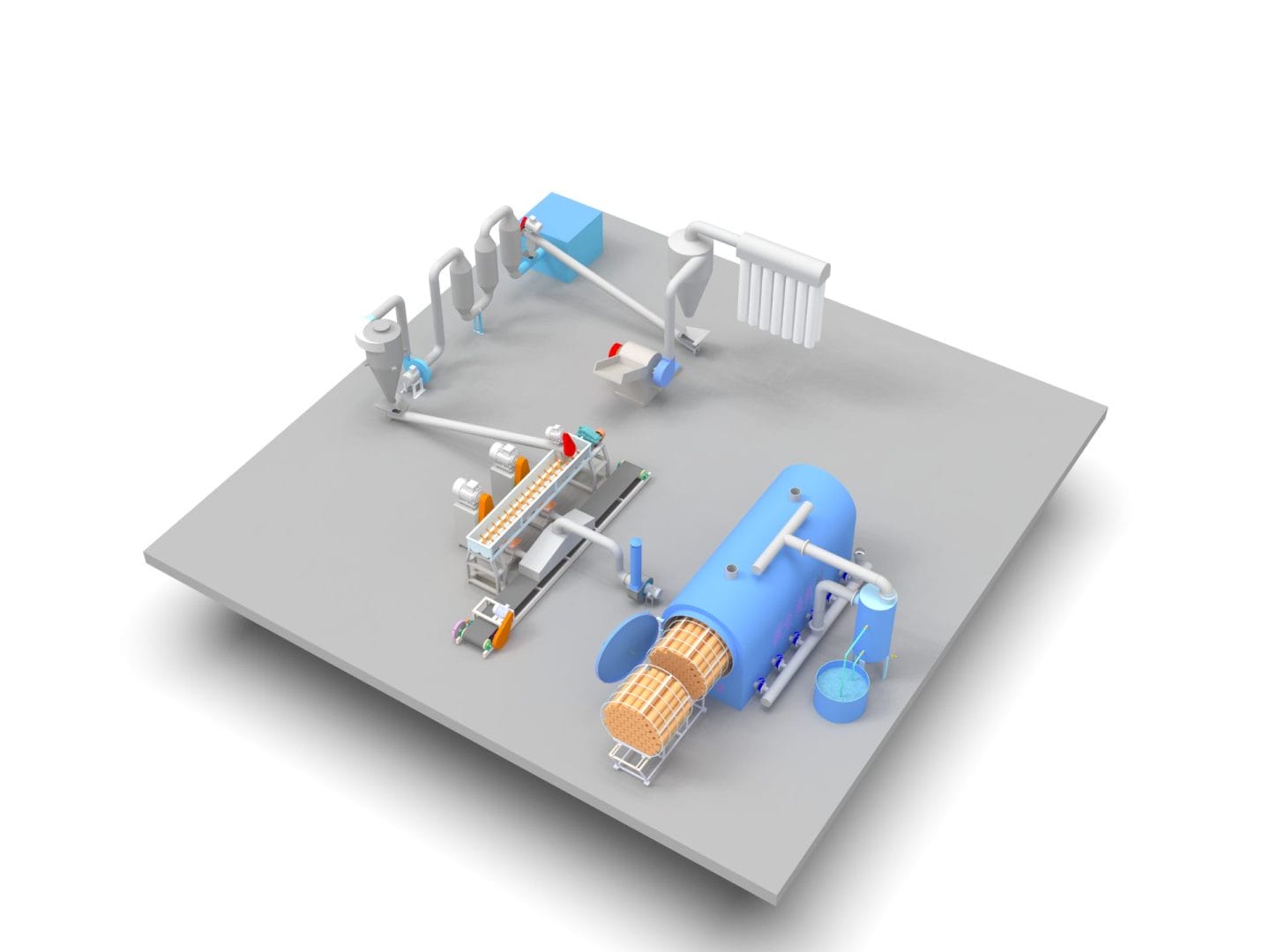

فرن الكربنة الأفقي لآلية الفحم adopts advanced hot gas flow carbonization technology, can carbonize Mechine-made Carbon Rods, greatly improve the carbonization rate,سهل العمل,environmental protection and energy saving, يمكن أن توفر الكثير من الطاقة,من معدل الكربنة الأصلي حوالي 80% زادت إلى 99%.

Unique Horizontal Carbonization Furnace for Mechanism charcoal Design

هذه هي المعلمات الفنية الرئيسية للمنتج, إذا كنت لا تعرف كيفية الاختيار, يمكنك إخبارنا بالمواد الخام التي تريد معالجتها. سوف نساعدك على اختيار أفضل منتج لك.

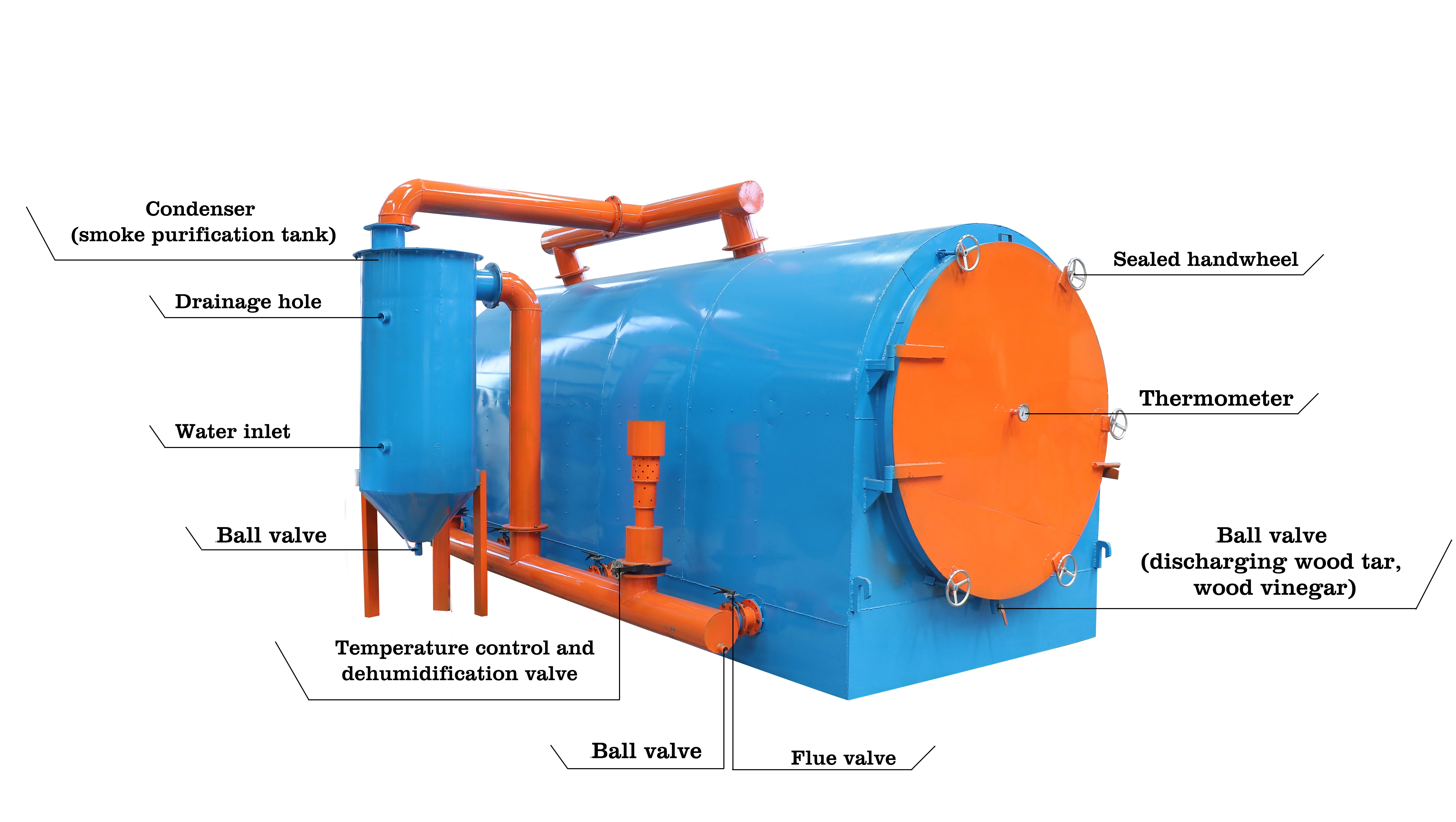

ميزان الحرارة : قياس درجة حرارة الفرن.

غطاء الختم:ختم للحفاظ على درجة الحرارة داخل الفرن, لضمان تأثير جيد للسبنية.

غرفة الاحتراق: أطلق الفرن وجعل الفحم. هناك الغاز القابل للاحتراق لإنتاجه ويمكن إرسال هذا الغاز إلى أسفل فم النار للسماح للجهاز بتسخين.

غرفة الكربنة:المواد الخام تتحلل حراريًا في غرفة الاحتراق لتوليد كمية كبيرة من حمض الخليك, الميثانول, القطران الخشبي وغيرها من المنتجات السائلة; أنتجت أيضًا غازات قابلة للاحتراق مثل الميثان والإيثيلين.

نظام استرداد الدخان:يتم علاج الغازات القابلة للاشتعال عن طريق تنقية غاز المداخن, ويعيد إلى آلة الكربنة للحرق, توفير الحرارة لفرن الكربنة, زيادة درجة حرارة الفرن, وتوليد الكربون في درجات حرارة عالية.

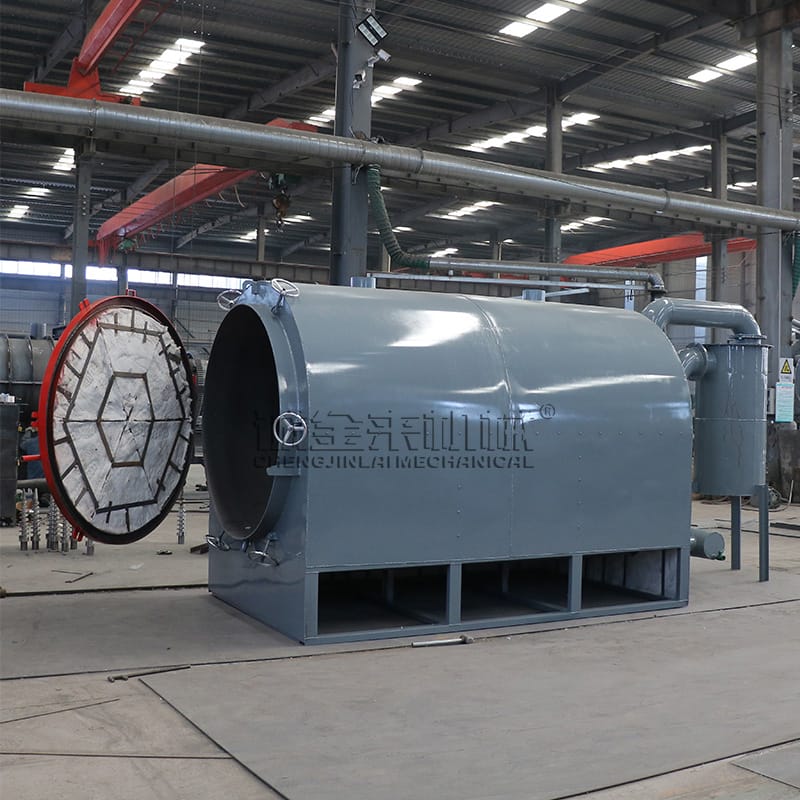

تغذية وتفريغ مريحة

The horizontal carbonizing furnace is eguipped with rails and carts, والتي يمكن أن تستفيد بالكامل من المساحة في thefurnace, وهو أكثر ملاءمة لاستخدام ويقلل من كثافة العمالة للعمال.

What is the operating instructions of Horizontal Carbonization Furnace for Mechanism charcoal?

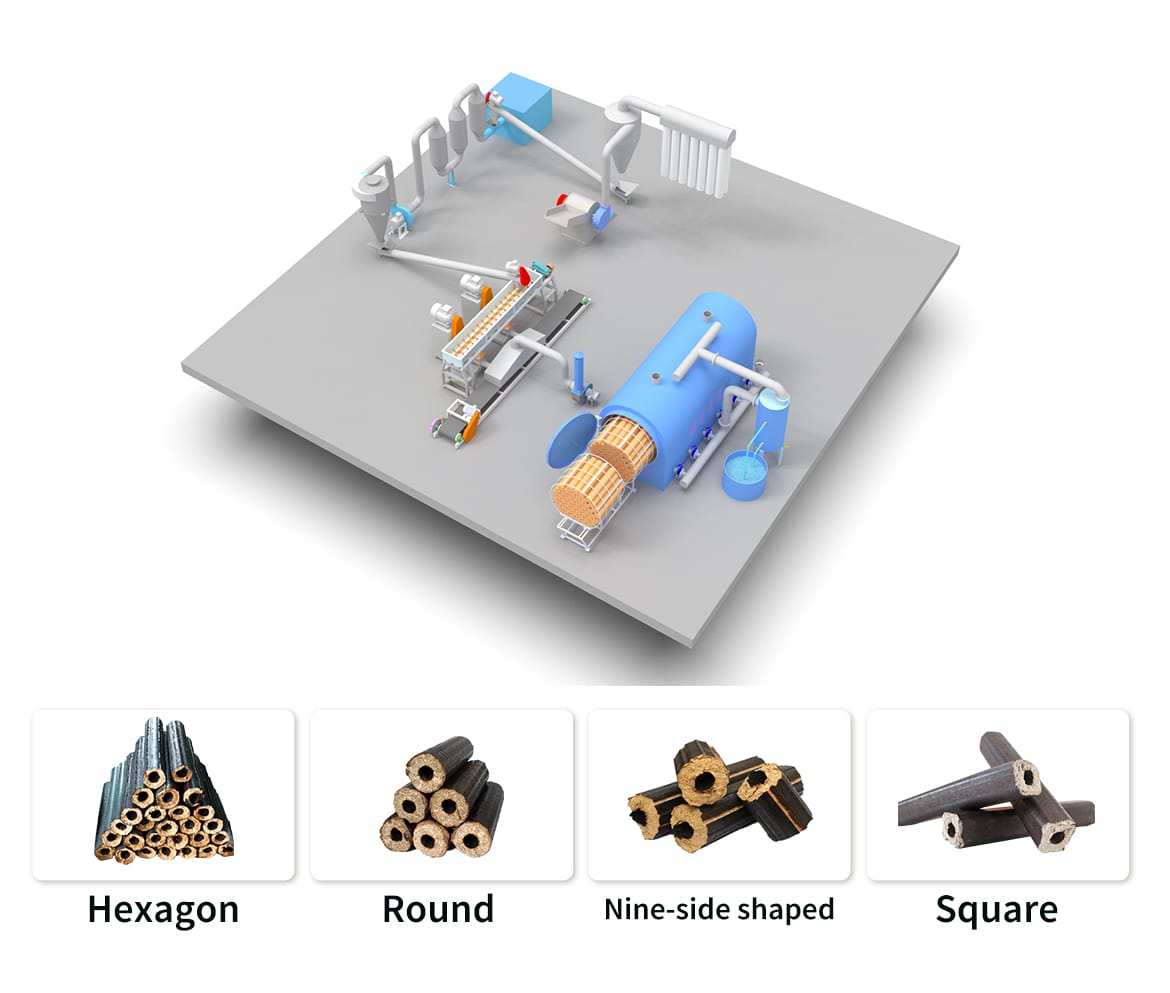

Work process of Horizontal Carbonization Furnace for Mechanism charcoal product line

- 1. Crush the raw material into a powder with a size of 2-5mm.

- 2. Use rotary dryer to make material dry until the moisture is 8%-12%.

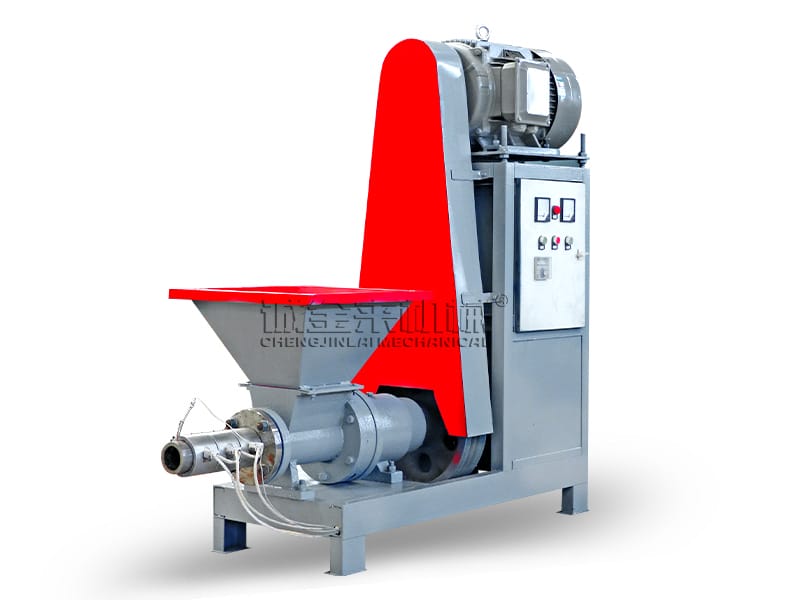

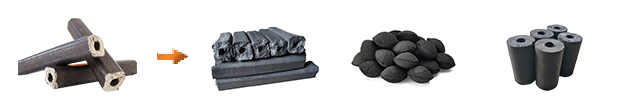

- 3. Use sawdust briquette equipment to moulding different shape and size of product.

- 4. After being pressed by the briquetting machine, it is finally placed in the carbonization furnace for carbonization it will become smokeless charcoal.

الوظائف ذات الصلة:

Why do so many manufacturers choose Weiwa Horizontal Carbonization Furnace for Mechanism charcoal?

الأسهم

لدينا الكثير من الأسهم,يمكننا التسليم بسرعة.

معتمد

لقد حصلنا على العديد من cerification,لذلك لا تحتاج إلى القلق بشأن جودة جهازنا.

مصنع

نحن المصنع,يمكننا تزويد نفس آلة الجودة بسعر أقل.

شركة Machinery Machinery Co., المحدودة. هي الشركة المصنعة المحترفة لآلات تصنيع الفحم في الصين. التحسين المستمر والابتكار هو فلسفة الإنتاج لدينا. مبدأنا: البقاء على قيد الحياة من الجودة, تطوير بالائتمان, الجودة أولا, الائتمان أولا, القائمة على النزاهة, العميل أولا.

WeChat

WeChat

+8613838093177

+8613838093177