في الآلات Weiwa, we believe that innovation thrives where sustainability meets industrial advancement. حديثاً, we proudly loaded and shipped one of our flagship products — the Continuous Carbonization Furnace — to a valued client in India. This event not only marks a major milestone in our global expansion but also reinforces our commitment to providing energy-efficient, environmentally friendly solutions tailored to regional needs.

In this blog post, we invite you behind the scenes of our delivery process, explore the scientific principles behind continuous carbonization furnaces, share insights from pre-shipment testing, and assess the immense potential of continuous carbonization technology in the evolving Indian market.

The Role of فرن الكربنة المستمر in Sustainable Development

As industries across the globe pivot toward sustainable practices, biomass carbonization has gained remarkable traction. At its core, a continuous carbonization furnace is a state-of-the-art system designed to convert biomass materials such as coconut shells, رقائق الخشب, الخيزران, نشارة الخشب, and agricultural residues into high-quality charcoal or biochar through an oxygen-limited thermal decomposition process.

Unlike traditional kilns that operate in batches, continuous carbonization furnaces offer uninterrupted feeding and discharging of feedstock, enabling round-the-clock production with minimal manual intervention. This results in higher efficiency, reduced labor costs, and more consistent product quality.

For countries like India, where agriculture is a vital economic pillar and biomass availability is abundant, the implementation of advanced charcoal making machines can significantly contribute to both rural employment and environmental conservation.

Unveiling the Demand for Continuous Carbonization Furnace in India

India stands at a unique crossroads of rapid industrialization, rising ecological awareness, and governmental support for green technologies. The demand for a continuous carbonization furnace in India is driven by multiple factors:

Abundant Biomass Resources

With millions of tons of agricultural waste generated annually, India offers a readily available feedstock supply for carbonization processes. Materials like rice husks, قصب السكر, corn cobs, and groundnut shells are ideal for conversion into charcoal, supporting decentralized production models even in rural areas.

Government Initiatives and Environmental Policies

The Indian government’s push toward renewable energy and reduced dependence on fossil fuels aligns perfectly with the capabilities of continuous carbonization technology. Schemes promoting clean cooking fuel alternatives and bans on single-use plastics further amplify the need for sustainable charcoal production.

Growing Commercial Applications

Beyond domestic cooking fuel, charcoal produced via continuous carbonization furnaces finds applications in metallurgy, ترشيح المياه, تعديل التربة (الفحم الحيوي), and activated carbon manufacturing — sectors witnessing robust growth in India.

It is within this fertile landscape that Weiwa Machinery positions its continuous carbonization furnace for India, offering customized configurations to suit local raw materials and production scales.

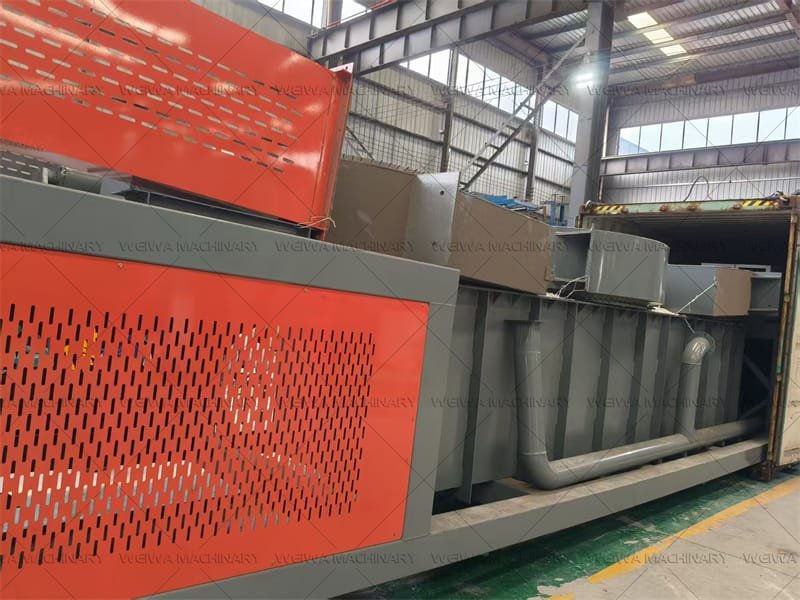

Behind the Scenes – Loading and Shipment to India

Our recent delivery was the culmination of weeks of meticulous preparation. The continuous carbonization furnace, mounted on a reinforced steel base for stability during transit, underwent rigorous quality checks and performance tests before packaging. Given the complexity of the equipment and the long journey to India, special attention was paid to corrosion protection, component safety, and modular disassembly for easier on-site reassembly.

The loading process was executed with precision at our manufacturing facility. Hydraulic forklifts positioned the main furnace body, control cabinet, gas purification unit, and conveyor systems onto shipping pallets. Each module was shrink-wrapped and secured to prevent movement during oceanic transport.

Accompanied by a team of experienced logistics coordinators and multilingual technical documents, the consignment set sail from Shanghai Port destined for one of India’s industrial hubs. We ensured compliance with all international export-import protocols and maintained constant communication with our Indian partners to streamline customs clearance and final-mile delivery.

How Continuous Carbonization Furnace Works?

To appreciate the value of our technology, it’s essential to understand how a continuous carbonization furnace operates. Unlike batch-type kilns that require loading, التدفئة, cooling, and unloading cycles, continuous units function much like an assembly line.

Key Process Stages

- Feeding System: Pre-processed biomass enters the furnace via a sealed screw conveyor, ensuring minimal heat loss and air ingress.

- Carbonization Zone: داخل الفرن, the material undergoes pyrolysis at controlled temperatures between 500°C and 700°C. In the absence of oxygen, volatile gases are released and subsequently recycled to provide heat for the process—making it highly energy efficient.

- معالجة غاز العادم: Harmful fumes pass through a multi-stage purification system involving condensers, scrubbers, and filters, capturing tar, particulate matter, and acidic components.

- Discharge Unit: Once carbonized, the charcoal exits the reactor through a cooling discharger, ready for packaging or further processing.

This seamless operation ensures uniform carbonization, reduces emissions, and maximizes energy recovery — advantages that position continuous carbonization furnaces as a superior alternative to conventional methods.

Pre-Shipment Trial Run – Witnessing Excellence in Action

قبل الإرسال, our engineering team conducted a full-scale trial run of the continuous carbonization furnace to validate performance metrics and ensure alignment with the client’s expectations.

Test Parameters and Results

Using a mixed feedstock of coconut shells and hardwood chips — common in southern India — we fed material into the furnace at varying rates. The system maintained a steady temperature curve without fluctuation, demonstrating excellent thermal regulation. Charcoal output exceeded design specifications, achieving a fixed carbon content above 85% and low ash content under 3%.

Notably, the furnace operated continuously for 72 hours without downtime, affirming its robustness and reliability. Emissions data showed compliance with European environmental standards, reassuring clients of its eco-friendly credentials.

Client representatives who joined the virtual walkthrough expressed strong confidence in the system’s ability to meet their production targets while adhering to India’s tightening emission norms. This successful demonstration underscored why Weiwa’s continuous carbonization furnace price represents not just a cost, but a long-term investment in productivity and sustainability.

Continuous Carbonization Furnace Price – Value Beyond Cost

A frequent question we receive revolves around the continuous carbonization furnace price. While initial capital expenditure may vary based on capacity, automation level, والتخصيص, it’s crucial to evaluate cost through a holistic lens.

Return on Investment Factors

- Operational Efficiency: Continuous operation slashes labor and energy expenses compared to batch systems.

- Feedstock Flexibility: Ability to process diverse biomasses protects against seasonal shortages.

- Product Versatility: High-quality charcoal opens doors to premium markets including activated carbon and industrial fuel sectors.

- الامتثال البيئي: Avoidance of penalties and eligibility for green subsidies enhance financial viability.

In India, where access to affordable clean energy remains a challenge, our charcoal making machine in India empowers entrepreneurs to build profitable ventures while contributing to national sustainability goals. We work closely with clients to tailor financing options and after-sales support that make the transition smoother.

Market Outlook – The Future of Continuous Carbonization Furnace in India

Looking ahead, the outlook for continuous carbonization furnace deployment in India appears exceptionally promising. Several trends are converging to create a fertile environment for growth:

Rural Entrepreneurship and Self-Reliance

Government programs like “Make in India” and “Atmanirbhar Bharat” (Self-Reliant India) encourage localized manufacturing. Small and medium enterprises (الشركات الصغيرة والمتوسطة) equipped with compact continuous carbonization units can generate income from farm waste, reducing open-field burning and associated pollution.

Urban Waste Management Solutions

With burgeoning urban populations, municipal solid waste presents a new frontier. Advanced carbonization techniques enable conversion of segregated organic fractions into useful charcoal, easing landfill burdens and creating circular economy models.

إمكانات التصدير

High-grade charcoal and biochar produced domestically can cater to international markets demanding sustainable inputs for agriculture and industry. Indian manufacturers leveraging Weiwa’s technology stand to gain a competitive edge in global trade.

Given these dynamics, we foresee a surge in inquiries for continuous carbonization furnaces in India over the coming decade. Our strategic focus includes establishing regional service centers, training local technicians, and collaborating with research institutions to adapt our systems to evolving feedstocks and regulatory landscapes.

لماذا تختار آلات Weiwa?

Based in China with a global vision, Weiwa Machinery has spent over a decade perfecting the art and science of carbonization equipment. Our strengths lie not only in engineering excellence but also in understanding diverse market needs.

نحن نقدم:

- حلول مخصصة: From small-scale units for startups to large industrial lines for conglomerates.

- Proven Technology: Patented designs ensure higher yield, انخفاض الانبعاثات, and longer service life.

- Global Support Network: Spare parts availability, remote diagnostics, and onsite training across continents.

- Commitment to Sustainability: Every machine reflects our pledge to reduce carbon footprints and promote green economies.

Our recent shipment to India reaffirms our role as a trusted partner in the worldwide transition to cleaner energy. Whether you seek a continuous carbonization furnace for India or aim to explore charcoal making machine applications globally, Weiwa Machinery stands ready to empower your vision.

Conclusion – Igniting Progress Across Borders

Shipping our continuous carbonization furnace to India was more than a business transaction; it was a bridge connecting innovation with impact. From the bustling fields of Punjab to the coastal plains of Kerala, this technology carries the promise of transforming waste into wealth, darkness into light, and scarcity into abundance.

As we monitor the installation progress and await feedback from our Indian partners, we remain inspired by the possibilities that lie ahead. The journey of a single furnace exemplifies how engineering prowess, when coupled with empathy for planetary and human welfare, can spark revolutions — quietly, powerfully, and perpetually.

Welcome aboard the future of charcoal production. Welcome to Weiwa Machinery.

عن آلات ويوا

Weiwa Machinery is a leading manufacturer specializing in biomass energy equipment, including continuous carbonization furnaces, آلات صنع الفحم, and auxiliary systems for environmental protection. With a strong R&D foundation and a customer-centric approach, we serve clients in over 30 بلدان, delivering cutting-edge solutions that drive sustainable development and industrial progress.

WeChat

WeChat

+8613838093177

+8613838093177