The Growing Need for Biomass Solutions in Sierra Leone

In Sierra Leone, where access to clean cooking energy and sustainable fuel sources remains a challenge, the demand for efficient sawdust extrude machinesوsawdust briquetting machines is rapidly growing. كشركة رائدة في هذا المجال, آلات ويوا recently completed the shipment of a complete sawdust briquette machine production line to Sierra Leone, marking a significant step toward promoting eco-friendly charcoal production in the region.

The Advantage of Sawdust Briquetting Machine

Deforestation and Charcoal Dependency in Sierra Leone

Sierra Leone, مثل العديد من الدول النامية, relies heavily on traditional wood charcoal for cooking and heating. This practice leads to إزالة الغابات, soil degradation, and health hazards from indoor smoke inhalation. The need for a renewable, cost-effective alternative has never been more urgent.

Converting Sawdust into Dense, Clean-Burning Briquettes

لديناآلات بثق نشارة الخشبوsawdust briquetting machines transform waste sawdust into high-density briquettes that burn longer and cleaner than traditional charcoal. These briquettes are made by compressing sawdust under high pressure without the need for added binders, making them an eco-friendly and economical fuel source.

By introducing Weiwa’s advanced briquetting technology, Sierra Leonean entrepreneurs and small businesses can now produce fuel locally, reduce deforestation, and generate income from waste materials.

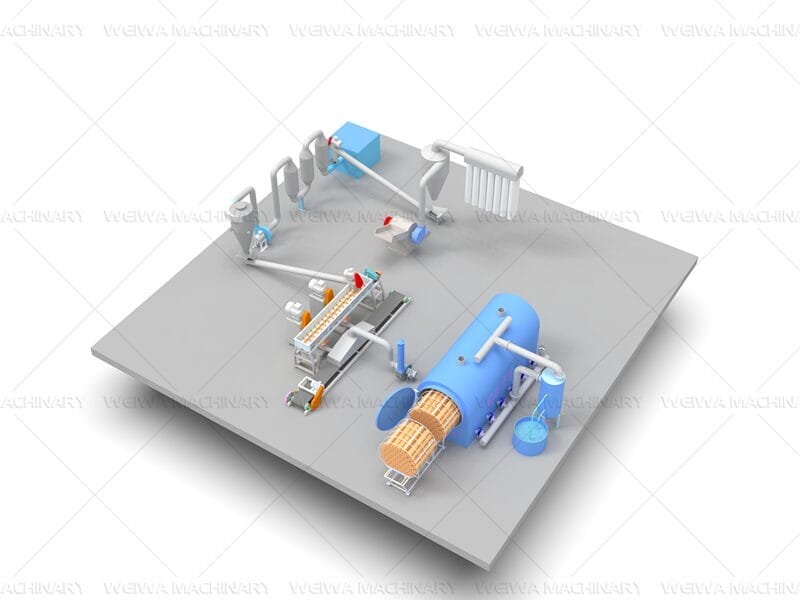

Inside Weiwa’s Sawdust Briquette Machine Production Line

Key Components of the Shipped Equipment

The shipment to Sierra Leone includes:

- Sawdust Extruder Machine: Compresses sawdust into dense rods or pucks, ideal for further processing.

- Sawdust Briquetting Machine: Presses sawdust into uniform briquettes using high pressure and heat.

- Drying System: Ensures briquettes are properly dried for storage and combustion.

- الناقل & Feeding System: Automates the workflow for efficient production.

Each machine is engineered for متانة, low maintenance, and high output, tailored to Sierra Leone’s operational conditions.

How the Briquetting Process Works?

- جمع المواد الخام: Sawdust from local mills or woodworking shops is collected.

- تجفيف (إذا لزم الأمر): Moisture content is reduced to optimal levels (8-12%) for efficient binding.

- Compression: والطارد نشارة الخشب or briquetting machine applies intense pressure, forming solid briquettes.

- تبريد & التغليف: Briquettes are cooled and prepared for distribution.

This process not only reduces waste but also creates a marketable product that can be sold as a cleaner cooking fuel.

The Shipment Process to Sierra Leone

Pre-Shipment Preparations

Before dispatching the sawdust briquette machine production line, Weiwa’s team conducts:

- Quality inspections to ensure all components meet international standards.

- Customs documentation to facilitate smooth import into Sierra Leone.

- Client consultation to understand specific production needs.

شحن & Logistics

The machinery was carefully packed and transported via sea freight to Freetown, Sierra Leone’s main port. Our logistics partners ensured secure handlingلمنع الضرر أثناء النقل.

Client Onboarding & تمرين

Upon arrival, Weiwa’s technicians will provide:

- Installation guidance to set up the production line.

- Operational training for local staff.

- Ongoing technical support to ensure smooth production.

This hands-on approach ensures that Sierra Leonean clients can maximize the efficiency of their briquetting operations.

The Future of Biomass Energy in Sierra Leone

Empowering Local Entrepreneurs

With Weiwa’s sawdust extruder and briquetting machines, local businesses in Sierra Leone can:

✔Reduce reliance on firewood & فحم

✔Create jobs in biomass production

✔Generate income from waste materials

Environmental Impact

By promoting sustainable fuel alternatives, Sierra Leone can:

Slow deforestation rates

Reduce harmful emissions from traditional charcoal

Encourage circular economy practices

Weiwa Machinery’s Commitment to Sustainable Solutions

The successful shipment of our sawdust briquette machine production line to Sierra Leone highlights Weiwa’s dedication to providing affordable, فعال, and eco-friendly biomass solutions worldwide. Through our advanced sawdust extruder and briquetting technologies, we aim to help developing nations like Sierra Leone transition to cleaner energy while boosting local economies.

For more information on our sawdust briquetting machines, extruders, or complete production lines, اتصل بآلات Weiwa اليوم.

عن آلات ويوا

آلات ويواهو الشركة المصنعة الرائدة لbiomass briquetting equipment, متخصص فيsawdust briquette machines, extruders, وأكمل خطوط الإنتاج. مع أكثر 30 سنوات من الخبرة, نحن نخدم العملاء فيزيادة 50 بلدان, توفيرمتينة, high-efficiency machines tailored to local needs. التزامنا بجودة, ابتكار, ودعم العملاء makes us a trusted partner in the global transition to sustainable energy.

WeChat

WeChat

+8613838093177

+8613838093177