مقدمة

With global biomass energy market projected to reach $302 مليار من قبل 2030 (بلومبرجنيف), أصبح تحويل النفايات الزراعية إلى الفحم أمرًا ضروريًا للبيئة وقابل للحياة اقتصاديًا. في الآلات Weiwa, our engineered solutions – بما في ذلكhigh-output sawdust extrude machines, automated briquette presses, وفعال الطاقة أفران الكربنة – transform waste into premium fuel with 40% higher calorific value than raw biomass.

The Growing Importance of Biomass Charcoal Machines

Biomass charcoal is an eco-friendly alternative to traditional fossil fuels. Made from agricultural waste like قشر الأرز, نشارة الخشب, and wood chips, it reduces deforestation and carbon emissions.

What Is a Sawdust Extrude Machine?

أآلة البثق نشارة الخشب compresses raw biomass (نشارة الخشب, قشور الأرز, إلخ.) into dense briquettes. By applying high pressure and heat, lignin in the material binds particles without additives. Our machines ensure high output with low energy consumption.

Key Features of Weiwa’s Sawdust Extrude Machine

- High-pressure compression for dense, قوالب حرق طويلة

- Low maintenance and energy-efficient operation

- Adjustable mold sizes for customized briquette shapes

آلة البثق نشارة الخشب: Turning Waste into Valuable Fuel

نشارة الخشب, a byproduct of wood processing, is often discarded. لكن, لديناآلة البثق نشارة الخشب compresses it into compact briquettes, perfect for heating and industrial applications.

Benefits of Using Sawdust Charcoal

- Reduces agricultural waste pollution

- Produces clean-burning, smokeless fuel

- Cost-effective compared to traditional charcoal

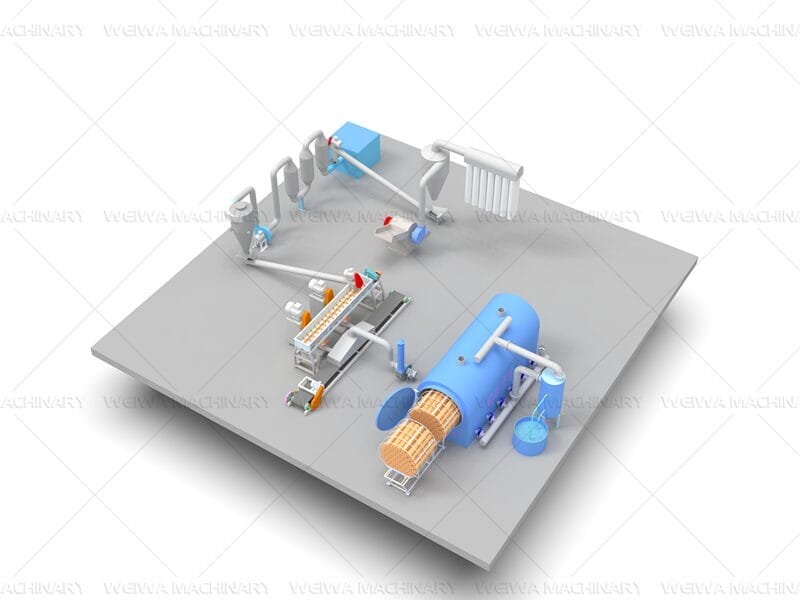

The Charcoal Production Line: From Raw Material to Finished Product

Weiwa Machinery offers a full charcoal product line, from raw material processing to final briquette packaging. Our integrated solutions include:

خطوة 1: سحق & تجفيف

Biomass is crushed and dried to <20% moisture for optimal briquetting.

خطوة 2: Briquetting with a Sawdust Extrude Machine

وآلة البثق نشارة الخشب forms briquettes under high pressure

خطوة 3: Carbonization in a Horizontal Carbonization Furnace

Briquettes are heated (500–800°C) in an oxygen-limited فرن الكربنة الأفقي, converting them into charcoal.

خطوة 4: التغليف & تخزين

The final charcoal is cooled, تعبئتها, and stored for distribution.

Why Choose Weiwa Machinery for Your Charcoal Production Needs?

معزيادة 30 سنوات من الخبرة في الصناعة, Weiwa Machinery has established itself as a trusted leader in charcoal production technology. لديناexpert engineering team ensures every machine meets the highest standards of quality, متانة, and efficiency. على عكس الموردين العامين, we provide full-service support, بما في ذلكon-site installation and commissioning, so your production line runs smoothly from day one.

We understand that every client has unique needs, which is why we offer fully customizable solutions—whether you need a compact briquetting system or a large-scale carbonization plant. Our machines are built for long-term performance with minimal maintenance, reducing downtime and maximizing productivity.

بالإضافة إلى ذلك, we prioritize environmental compliance, ensuring our equipment meets international emissions and safety standards. From technical consultation to after-sales service, our dedicated team is committed to your success.

Choose Weiwa Machinery—where experience, ابتكار, and reliability come together to power your charcoal business.

حول آلات ويوا

آلات ويواهو الشركة المصنعة الرائدة لمعدات معالجة الكتلة الحيوية, بما في ذلكsawdust extrude machines, الآلة briquette, وrice husk charcoal machines. مع أكثر 15 سنوات من الخبرة, we provide turnkey solutions for sustainable fuel production.

Want to build a charcoal production line? Get a Free Customized Plan from Weiwa’s engineers today!

Tel/WhatsApp:+86 1838093177

بريد إلكتروني:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177