Meeting Indonesia’s Biomass Energy Needs

في السنوات الأخيرة, Indonesia has seen a growing demand for sawdust charcoal making machine lines, driven by the need for sustainable fuel alternatives and efficient biomass utilization. فيآلات ويوا, we specialize in providing أفران الكربنة الأفقية that transform sawdust logs into briquettes with high efficiency.

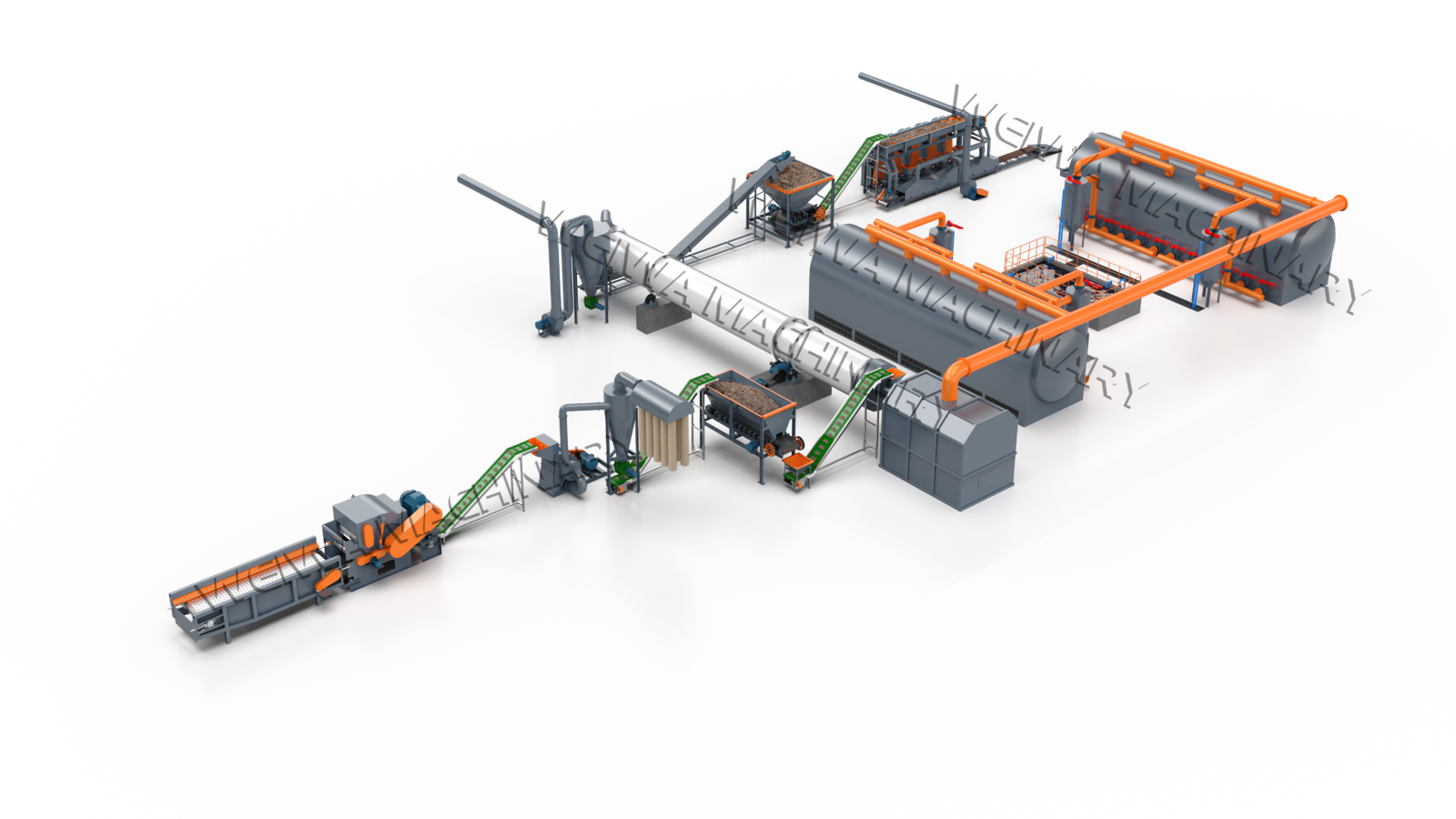

Our latest project involved designing and installing a Biomass briquette charcoal product lineفي إندونيسيا, tailored to our client’s specific production needs.

Designing the Perfect Solution for Indonesian Customer

Understanding Client Requirements

Our Indonesian client required a high-capacity sawdust charcoal production line. After analyzing their input materials (mainly sawdust logs) and desired output (فحم الفحم), our engineers developed a customized 3D design for the فرن الكربنة الأفقي.

The key considerations included:

- Optimal carbonization temperature control

- Efficient smoke emission management

- Continuous feeding and discharge system

- Energy-saving and low-maintenance operation

3D Modeling & Simulation

Before manufacturing, our engineering team created a detailed 3D modelمنفرن الكربنة الأفقي, ensuring all components—such as the carbonization chamber, heating system, and conveyor belt—were perfectly aligned for smooth operation.

This digital simulation helped us:

- Minimize design flaws before production

- Ensure the furnace could handle 5 tons/hour throughput

- Optimize space and energy efficiency

On-Site Installation & Testing in Indonesia

Engineer Deployment for Machine Setup

Once the فرن الكربنة الأفقي was manufactured, our team of experienced engineers traveled to Indonesia to oversee the installation and commissioning of the entire sawdust charcoal making machine line.

The installation process included:

- Positioning the horizontal carbonization furnace in the client’s facility

- Connecting the sawdust logs machine to the carbonization unit

- Integrating the briquette pressing system for final product formation

Testing & Performance Optimization

بعد التثبيت, we conducted real-time testing to ensure the 5-ton/hour capacity was achieved while maintaining high-quality charcoal output. Key adjustments included:

- Fine-tuning temperature settings for optimal carbonization

- Ensuring smooth sawdust feeding into the furnace

- Monitoring smoke emission levels for environmental compliance

The client was impressed with the machine’s efficiency and durability, confirming that the فرن الكربنة الأفقي met their production goals.

Why Choose Weiwa Machinery’s Horizontal Carbonization Furnace?

1. كفاءة عالية & سعة كبيرة

لدينافرن الكربنة الأفقي is designed for العملية المستمرة, processing حتى 5 tons of sawdust per hour—making it ideal for industrial-scale charcoal production.

2. حلول قابلة للتخصيص

Unlike one-size-fits-all machines, آلات ويواengineers each system based on client requirements, ensuring the best performance for their specific raw materials (على سبيل المثال, sawdust logs).

3. عملية صديقة للبيئة

وفرن الكربنة الأفقي includes advanced smoke filtration, reducing harmful emissions and ensuring environmental compliance.

4. Reliable After-Sales Support

يوفر فريقناon-site installation, تمرين, and maintenance support to ensure smooth long-term operation—just like we did in Indonesia.

Weiwa Machinery’s Success in Indonesia

This project highlights Weiwa Machinery’s ability to deliver turnkey sawdust charcoal production solutions, from 3D design to on-site installation. لدينافرن الكربنة الأفقي proved to be a موثوق, high-capacity solution for our Indonesian client, successfully transforming sawdust logs into briquettes at a 5-ton/hour rate.

إذا كنت تبحث عنtrusted partner in biomass carbonization, Weiwa Machinery is here to help. Contact us today to discuss your sawdust charcoal making machine line needs.

عن آلات ويوا

آلات ويواهو الشركة المصنعة الرائدة لbiomass carbonization and briquetting equipment, متخصص فيأفران الكربنة الأفقية, sawdust logs machines, و complete charcoal production lines. With years of experience in exporting to Indonesia and other Southeast Asian markets, we provide مخصصة, high-efficiency solutions for turning waste biomass into valuable charcoal products.

التزامنا بجودة, ابتكار, ودعم العملاء ensures that every client receives a موثوق, high-performing machine tailored to their needs.

WeChat

WeChat