In an era where sustainable energy is no longer a choice but a necessity, biomass solutions are gaining unprecedented traction across developing economies. من بين هؤلاء, charcoal briquettes—particularly those formed using advanced machinery like a Ball Charcoal Briquettes Machine—are emerging as a cleaner, cost-effective alternative to traditional fuels. As We iwa Machinery, with over thirty years of industrial expertise, we proudly announce the recent shipment of our state-of-the-art charcoal ball press machine production line to India, marking a significant step in supporting India’s green transition.

فهم Charcoal Ball Press Machine and Its Role in Sustainable Development

What Is a Charcoal Ball Press Machine?

At its core, a Charcoal Ball Press Machine is a mechanical device engineered to compress powdered charcoal or biomass materials into solid, easily transportable briquettes. These machines are vital in converting loose carbonized matter into high-density fuel blocks that burn efficiently and cleanly. The resulting product, often referred to as charcoal briquettes, serves as an eco-friendly substitute for firewood, الفحم, and kerosene in many households and industries.

The mechanism typically involves feeding raw material into a compression chamber, applying hydraulic or mechanical pressure, and extruding it through a die to form uniformly shaped balls or logs. The end product has low moisture content, consistent calorific value, and minimal smoke emissions when burned.

Why the Ball Charcoal Briquettes Machine Matters?

When discussing making charcoal balls, especially in regions like India where millions still rely on inefficient cooking methods, the relevance of a Ball Charcoal Briquettes Machine becomes clear. It bridges the gap between raw biomass waste and usable, high-value fuel. Furthermore, the densification process reduces volume, enabling easier storage and transportation.

In India, agricultural residues such as rice husks, قذائف جوز الهند, قصب السكر, and groundnut shells provide abundant feedstock for charcoal production. Utilizing a charcoal ball press machine allows local manufacturers to convert this underused biomass into sellable products, promoting circular economy principles.

Market Potential of Charcoal Briquette Machines in India

India stands at a unique crossroads of ecological urgency and economic opportunity. Rapid urbanization, rising energy demands, and government incentives for renewable energy adoption have cultivated fertile ground for the expansion of the charcoal briquettes sector. Here’s why the market potential for our Charcoal Briquette Machine in India is particularly promising:

Environmental Drivers and Government Support

With one of the world’s largest populations relying on solid fuels for cooking, indoor air pollution remains a grave concern in India. The government’s push toward cleaner cooking technologies under initiatives such as the Pradhan Mantri Ujjwala Yojana aligns perfectly with the deployment of charcoal briquette solutions. علاوة على ذلك, various states offer subsidies and tax benefits for green manufacturing units, encouraging entrepreneurs to invest in systems like a charcoal ball press machine.

Rising Demand for Alternative Fuels

As global energy prices fluctuate and the environmental impact of fossil fuels becomes harder to ignore, industries and households alike are seeking affordable alternatives. Charcoal briquettes made using a charcoal ball press machine offer higher thermal efficiency and lower emissions compared to traditional wood or dung cakes. This positions them as a viable option for both domestic kitchens and small-scale industries such as brick kilns and foundries.

Localized Manufacturing and Employment Opportunities

One of the most compelling advantages of making charcoal balls in India is job creation. From raw material collection to machine operation and distribution, the entire value chain offers grassroots employment. For rural areas grappling with underemployment, setting up small briquette plants powered by a charcoal ball press machine can be transformative.

في الآلات Weiwa, we recognize these socio-economic dynamics and engineer our machines not just for performance, but also for accessibility and ease of use by local operators.

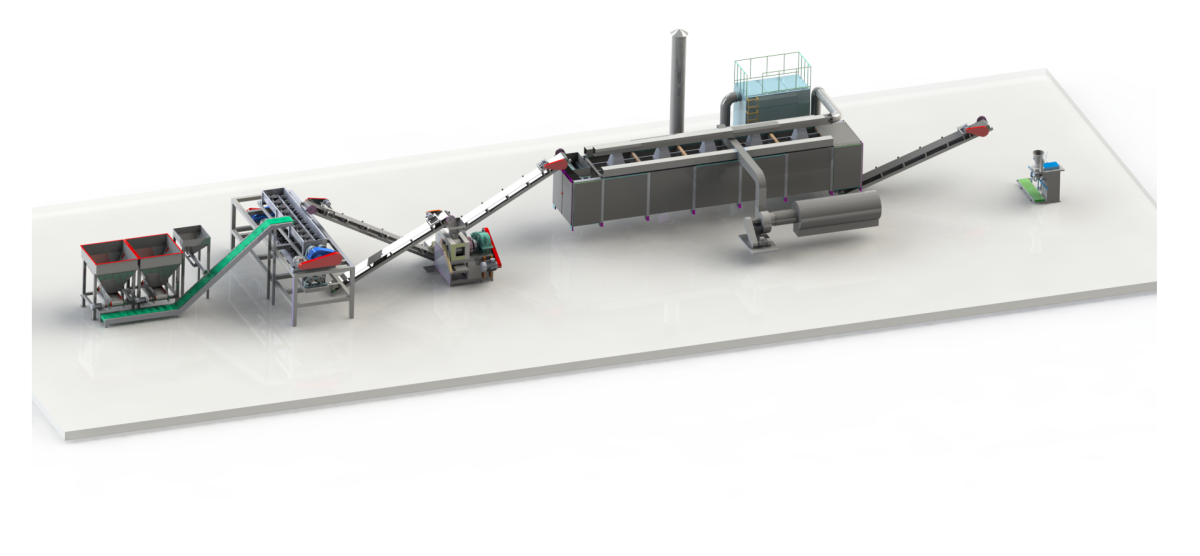

A Closer Look at the Charcoal Ball Press Machine Production Line

Delivering a single unit is one thing; providing an integrated Charcoal Briquette Machine production line is another. Our comprehensive setup supplied to India includes all essential components required for end-to-end briquette manufacturing—from raw material preparation to final packaging.

خط إنتاج كرة الفحم

Raw Material Processing Section

Before entering the ball charcoal briquettes machine, raw biomass must undergo carbonization and pulverization. Our production line features carbonization furnaces that ensure efficient conversion of organic waste into char powder. Following this, grinders reduce the char to uniform particle size, optimizing it for pressing.

The Core: Charcoal Ball Press Machine

The centerpiece of the line is, undeniably, the charcoal ball press machine. Designed for continuous operation, our model ensures high output with minimal downtime. Hydraulic systems maintain precise pressure, allowing customization of briquette density based on application needs. Whether producing pillow-shaped or spherical charcoal balls, our machine delivers consistency and durability.

Conveying and Cooling Systems

Post-compression, briquettes are transferred via conveyor belts to cooling racks. Controlled cooling prevents cracking and enhances structural integrity. This automated handling minimizes labor intervention and boosts production hygiene.

Packaging and Quality Control

To support commercial scalability, the line incorporates semi-automatic bagging systems. بالإضافة إلى ذلك, quality control checkpoints are installed to monitor briquette density, moisture level, and combustion characteristics, ensuring compliance with both national and export standards.

Such turnkey solutions exemplify how Weiwa Machinery supports clients from concept to commissioning, tailoring every detail to their operational context.

Making Charcoal Balls in India

While the prospects are bright, making charcoal balls in India does present specific challenges. Feedstock availability can vary seasonally, power supply may be inconsistent in rural zones, and local technical know-how might be limited. في الآلات Weiwa, we’ve factored these issues into our design philosophy.

Our machines are built to handle variable input materials and require minimal power due to optimized motor efficiency. Furthermore, our expert after-sales team provides hands-on training and remote troubleshooting, ensuring smooth operations even in resource-constrained environments.

Through strategic partnerships with regional suppliers and NGOs, we also assist clients in establishing reliable feedstock channels and accessing microfinance options for equipment acquisition.

Why Choose Weiwa Machinery for Your Charcoal Briquette Machine Needs?

مع أكثر 30 years of experience in the field of biomass processing equipment, Weiwa Machinery has established itself as a trusted name among global clients. Our journey began with a simple mission: to empower communities through green technology. اليوم, we serve customers across Asia, أفريقيا, and Latin America with a diverse portfolio of machinery tailored to local needs.

Decades of Engineering Excellence

Our R&D team continuously refines machine designs to enhance energy efficiency, user safety, and output quality. Every component, from the steel grade used in pressure chambers to the software logic controlling hydraulic operations, undergoes rigorous testing.

خدمة ما بعد البيع المهنية

We understand that investing in a charcoal ball press machine is a long-term commitment. That’s why we maintain a professional after-sales department fluent in multiple languages, ready to assist with installation, maintenance, and operator training. Our service network spans continents, ensuring rapid response times.

Customization and Site Planning

No two production sites are identical. We offer bespoke design services including layout planning, utility calculations, and compliance advisory. Clients receive detailed design drawings customized to their land size, workforce skill level, and production targets.

Whether you’re an entrepreneur exploring entry into biomass fuel manufacturing or a government agency scaling up rural employment programs, we invite you to connect with us for inquiries and quotations. Let Weiwa Machinery be your partner in building a greener future.

Lighting the Path to Sustainability with Weiwa Machinery

The shipment of our Ball Charcoal Briquettes Machine production line to India is more than a business transaction—it’s a testament to our commitment to global sustainability and inclusive growth. As India charts its course toward cleaner energy and reduced carbon dependency, technologies like the charcoal ball press machine will play a pivotal role in shaping that journey.

By enabling localized, فعال, and eco-conscious production of charcoal briquettes, we are helping communities embrace entrepreneurship while addressing urgent environmental challenges. With our legacy of excellence, customer-first approach, and holistic service offerings, Weiwa Machinery is uniquely equipped to support India’s vision for a brighter, cleaner future.

If you’re considering making charcoal balls in India or expanding your biomass operation, reach out to us today. Let’s build smarter fuel solutions together.

عن آلات ويوا

Weiwa Machinery is a leading manufacturer of biomass processing equipment with over 30 سنوات من الخبرة في الصناعة. Specializing in Charcoal Briquette Machines, Ball Charcoal Briquettes Machines, وأكمل خطوط الإنتاج, we provide customized engineering solutions, site planning, and professional after-sales support. Our dedicated team ensures each client receives personalized attention, from initial consultation and design drawings to installation and operator training. Contact us now to learn how our machinery can elevate your charcoal production venture.

- الغوغاء:+8613838093177

- Whatsapp:+8613838093177

- بريد إلكتروني:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177