The Rising Demand for Sustainable Charcoal Production

في السنوات الأخيرة, the global demand for الفحم الحيوي and high-quality charcoal has surged, مدفوعة بتطبيقاتها في الزراعة, طاقة, والاستدامة البيئية. أندونيسيا, with its abundant palm fiber waste, يقدم فرصة فريدة لتكربن الكتلة الحيوية بكفاءة.

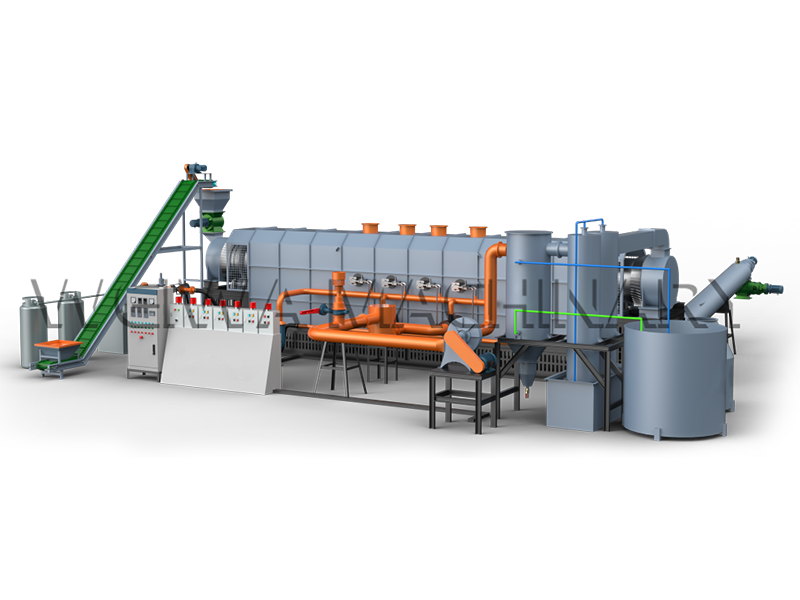

فيآلات ويوا, we recently completed the delivery of a complete continuous carbonization furnace production line to an Indonesian client, specializing in converting palm fiber into charcoal briquettesباستخدام أhoneycomb coal press machine. This project highlights our expertise in designing continuous carbonization furnaces for palm fiber, tailored for the Indonesian market.

Inefficient Carbonization Methods for Palm Fiber

Before partnering with Weiwa, our Indonesian client relied on traditional batch carbonization methods, which were:

- Time-consuming (long cooling and heating cycles)

- Labor-intensive (manual feeding and unloading)

- Low-yield (inconsistent carbonization quality)

بالإضافة إلى ذلك, Indonesia’s palm fiber waste (نتيجة ثانوية لإنتاج زيت النخيل) was underutilized, despite its high potential for biochar production.

Our client needed a continuous, automated solution that could:

✔ Process palm fiber efficiently

✔ Produce عالي الجودة من الفحم

✔ Operate 24/7 with minimal supervision

A Complete خط إنتاج فرن الكربنة المستمر

To meet these requirements, Weiwa designed and delivered a fully integrated production line, مشتمل:

1. Continuous Carbonization Furnace for Palm Fiber

لدينافرن الكربنة المستمر is specifically engineered for biomass materials like palm fiber, ضمان:

- كفاءة الكربنة عالية (حتى 90% conversion rate)

- التحكم في درجة الحرارة مستقرة (preventing material damage)

- Automated feeding and discharging (تقليل تكاليف العمالة)

This furnace is ideal for Indonesia’s tropical climate, ضمانdurable performance even in high-humidity conditions.

2. Honeycomb Coal Press Machine for Briquette Production

بعد الكربنة, وpalm fiber charcoal is transformed into high-density briquettesباستخدام لديناhoneycomb coal press machine. This ensures:

- Uniform shape and size (better combustion efficiency)

- Higher market value (briquettes are preferred over loose charcoal)

- Reduced transportation costs (compact storage)

3. Complete Production Line Integration

Our team in Indonesia handled:

- Site planning & layout design (optimized workflow)

- Equipment installation & تمرين (ensuring smooth operation)

- دعم ما بعد البيع (responsive maintenance)

هذاحل تسليم المفتاح allowed our client to start production quickly with minimal downtime.

Why Continuous Carbonization Furnaces Are the Future?

على عكس التقليديةكربنة الدُفعات, أفران الكربنة المستمرة offer:

Higher Efficiency

- Non-stop operation (no need for repeated cooling/heating)

- Faster processing (higher throughput)

Better Quality Control

- Uniform carbonization (consistent charcoal quality)

- Lower emissions (صديقة للبيئة)

Cost-Effective for Large-Scale Production

- Reduced labor costs (automated feeding)

- Lower energy consumption (optimized heat recycling)

For Indonesian clients, هذا يعنيhigher profitsوsustainable biomass utilization.

Palm Fiber Is The Ideal Raw Material for Biochar in Indonesia

Indonesia produces millions of tons of palm fiber waste annually, much of which goes unused. Our client recognized its potential as a low-cost, high-yield carbonization material because:

- ارتفاع محتوى الكربون (excellent for charcoal production)

- Abundant supply (readily available near palm oil mills)

- Low processing cost (minimal preprocessing needed)

By converting this waste into biochar and charcoal briquettes, our client not only generates revenue but also contributes to waste reduction and sustainability.

Why Indonesian Clients Choose Weiwa Machinery?

Our success in Indonesia is built on:

30+ سنوات من الخبرة

With decades of experience in carbonization technology, we understand the unique needs of different markets.

حلول مخصصة

Every client has different requirements—we provide tailored designs, drawings, and layout planningلتحقيق أقصى قدر من الكفاءة.

Complete Turnkey Delivery

From equipment manufacturing to on-site installation & تمرين, we handle everything.

Reliable After-Sales Support

لديناprofessional service team ensures smooth operations with quick maintenance and troubleshooting.

Partner with Weiwa for Your Carbonization Needs

Our project in Indonesia proves that Weiwa Machinery’s continuous carbonization furnaces are the best solution for palm fiber biochar production. معكفاءة عالية, low operating costs, and excellent scalability, our technology helps clients maximize profits while contributing to sustainability.

إذا كنت تبحث عنtrusted partner for continuous carbonization furnaces in Indonesia—or anywhere else—contact Weiwa Machinery today for a consultation and customized quote.

عن آلات ويوا

معزيادة 30 سنوات من الخبرةفيcharcoal and carbonization equipment manufacturing, آلات ويوا is a leading provider of أفران الكربنة المستمرة, الآلة briquette, وأكمل خطوط الإنتاج.

لدينافريق محترف بعد البيعيضمن24/7 support, custom design services, وon-site installation assistance. سواء كنت بحاجة إلى ملفcontinuous carbonization furnace for palm fiber, خشب, أو الكتلة الحيوية الأخرى, we deliver جودة عالية, reliable solutions tailored to your needs.

Contact us today for a free consultation and quotation!

- الغوغاء:+8613838093177

- Whatsapp:+8613838093177

- بريد إلكتروني:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177