مقدمة: The Rising Demand for Charcoal Extrusion Technology

The global shift toward sustainable fuel alternatives has catapulted آلات بثق الفحموrod charcoal briquette machines into the spotlight. As industries and households seek eco-friendly, high-energy BBQ fuels, يتحول المصنعون إلىcharcoal extrude lines to produce uniform, متينة متينة. فيآلات ويوا, مع أكثر 30 سنوات من الخبرة, we’ve witnessed firsthand how these machines solve production challenges while unlocking lucrative market opportunities.

Why Charcoal Extrude Machines Are a Game-Changer

The Core Functionality of a Charcoal Extruder

أآلة القضاء الفحم (or بثق الفحم) compresses carbonized biomass (على سبيل المثال, خشب, قذائف جوز الهند) into dense rods using high pressure and minimal binder. Unlike traditional molding, extrusion ensures:

- Uniform density (reducing breakage during transport).

- كفاءة احتراق أعلى (longer burn time for BBQs).

- قابلية التوسع (producing tons daily for industrial clients).

إمكانات السوق: Who Needs These Machines?

The demand spans:

- الشواء & Catering Industries: Restaurants and food trucks prefer rod-shaped briquettes for consistent heat.

- Industrial Fuel: Foundries and smelters use extruded charcoal for cost-effective energy.

- Agriculture: Charcoal improves soil quality (biochar applications).

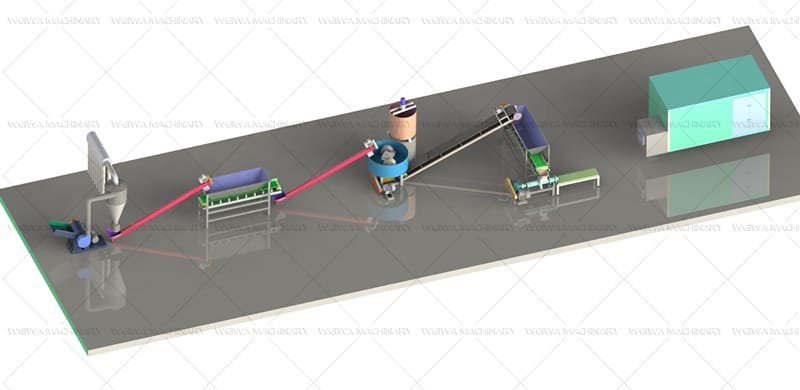

How Charcoal Extrude Lines Work: Step-by-Step

From Raw Material to Finished Briquettes

A typical charcoal extrude line includes:

- الكربنة: Raw biomass is pyrolyzed into charcoal (often outsourced or pre-processed).

- سحق & خلط: Charcoal is ground and mixed with a binder (على سبيل المثال, starch or clay, إذا لزم الأمر).

- Extrusion: وبثق الفحم pressurizes the mixture through a die, forming rods.

- تجفيف: Briquettes are air- or kiln-dried to solidify.

Customizing Your Production

Unlike generic solutions, عروض آلات Weiwa:

- Tailored die sizes (على سبيل المثال, 20مم, 40mm rods for different markets).

- Hydraulic/pneumatic extruder options (based on capacity needs).

Debunking Myths About Briquette Machines

“Extruded Briquettes Are Too Hard to Produce”

False. Modern آلات بثق الفحم automate pressure adjustments, reducing operator error.

“Rod Briquettes vs. Traditional Blocks: Which Wins?”

- Rods: Better for grills (even heat distribution).

- Blocks: Preferred for heating stoves (higher mass).

Keyword note: We highlight ”BBQ bar charcoal briquette machine” as the go-to for grilling applications.

لماذا تختار آلات Weiwa?

30+ سنوات من الخبرة

With decades in the industry, we’ve refined charcoal extrusion technology to ensure:

- 99% machine uptime.

- Energy-efficient designs (انخفاض التكاليف التشغيلية).

End-to-End Support

- Custom design drawings for your facility layout.

- خدمة بعد البيع: On-site training and spare parts availability.

- Field visits to optimize your charcoal extrude line.

اتصل بنا: Seizing the Charcoal Briquette Opportunity

وآلة القضاء الفحم market is booming, driven by demand for efficient, eco-friendly fuel. Whether you’re a startup or an established producer, investing in a rod charcoal briquette machine or complete extrude line ensures scalability and profitability.

فيآلات ويوا, we’re more than suppliers—we’re partners in your success. Let’s build your ideal production line together.

عن آلات ويوا

مع30+ سنوات من الخبرة, آلات Weiwa متخصصة فيcustomized charcoal and briquette production solutions. Our services include:

- Design drawings for optimized layouts.

- دعم ما بعد البيع المهني (تمرين, maintenance).

- OEM/ODM capabilities for unique client needs.

📞 اتصل بنا اليوم for a consultation or to request a quote. Let’s turn your biomass into profit—together.

- الغوغاء:+8613838093177

- Whatsapp:+8613838093177

- بريد إلكتروني:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177