Introdução aos briquetes de carvão com casca de coco

Nos últimos anos, a demanda por alternativas de combustível sustentáveis e ecológicas aumentou, fazendobrigas de carvão de concha de cocoum produto muito procurado. Derivado deconchas de coco, estes briquetes não são apenas uma excelente fonte de energia renovável, mas também uma oportunidade de negócio rentável. EmMáquinas de Weiwa, somos especializados em fornecer eficiênciabriquete de carvão de casca de coco fazendo linhas de produçãoque transformam resíduos de casca de coco em briquetes de carvão de alta qualidade com mínimo impacto ambiental.

Por que escolher casca de coco para produção de carvão?

Cascas de coco são umrico, material de biomassa denso em carbono que é uma excelente matéria-prima para a produção de carvão vegetal. Ao contrário do carvão vegetal tradicional, carvão de casca de coco oferece diversas vantagens:

- Alto teor de carbono fixo: Garante um tempo de queima mais longo e maior produção de energia.

- Cinza baixa & Emissão de fumaça: Torna-o mais limpo e mais ecológico.

- Durável & Estrutura Densa: Ideal para briquetagem sem excesso de agentes ligantes.

- Aproveitamento de Resíduos: Converte resíduos agrícolas em uma mercadoria valiosa.

Dados esses benefícios, brigas de carvão de concha de cocosão amplamente utilizados emChurrascos, Twys, mas smdítico, Aquecimento industrial, e até mesmo como carvão ativado.

Briquette de carvão de coco que fabrica a linha de produção

OLinha de produção de briqueta de carvão de casca de cocoenvolve vários estágios principais, cada um crucial para a produção eficiente de briquetes de alta qualidade. Abaixo está uma análise detalhada dotodo o fluxo de trabalho:

1. Coleção de matéria -prima & Pré-tratamento

O processo começa comcoletando cascas de coco secas, de preferência aqueles que foram secos ao sol ou mecanicamente para reduzir o teor de umidade (idealmente abaixo15%). A secagem adequada garante melhor eficiência de carbonização e reduz o consumo de energia em fases posteriores.

- Esmagando (Opcional): Se as conchas forem muito grandes, umtriturador ou moinho de martelopode ser usado para quebrá-los em pedaços menores para carbonização uniforme.

2. Carbonização – Transformando cascas em carvão

Oprocesso de carbonizaçãoé o coração da produção de carvão, onde as cascas de coco são aquecidas em um ambiente livre de oxigênio para decompor a matéria orgânica em carvão.

No vídeo, casca de arroz é usada como exemplo

Princípio de funcionamento da carbonização:

No vídeo a seguir, tomamos cascas de arroz como exemplo

- Cascas de coco são alimentadas em umforno de carbonização (forno rotativo, forno de tijolos, ou carbonizador contínuo).

- O forno é aquecido a300–600ºCem uma câmara privada de oxigênio (para evitar combustão).

- Acabou4–8 horas, as conchas sofrempirólise, liberando gases voláteis e deixando para tráscarvão sólido.

EmMáquinas de Weiwa, nós oferecemosEquipamento de carbonização avançadaque maximiza o rendimento enquanto minimiza as emissões.

3. Esmagando & Moendo o carvão

O resultanteCarcoal de concha de cocoé quebradiço e precisa ser triturado até formar um pó fino (geralmente3–5 mm ou mais fino) para briquetagem.

- UmTriturador de carvão ou moinho de marteloé usado para quebrar o carvão em um tamanho consistente.

- O tamanho adequado das partículas garantemelhor ligação e formação uniforme de briquetes.

4. Misturando com Binder (Opcional)

Embora alguns processos usembriquetagem sem aglutinante, muitos fabricantes adicionam umaglutinante natural (Por exemplo, amido, melaço, ou argila)para melhorar a coesão.

- O aglutinante é misturado com o pó de carvão em umtambor de misturapara garantir uma distribuição uniforme.

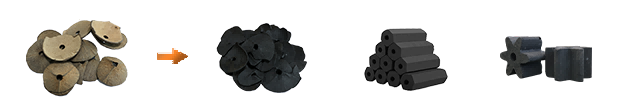

5. Briquetagem – Formando os Briquetes

Oprocesso de briquetagemcomprime o pó de carvão emuniforme, briquetes densosusando alta pressão.

Como funciona a briquetagem:

- Omistura de aglutinante de carvãoé alimentado em umBriquette de máquinas (geralmente uma prensa de parafuso ou prensa hidráulica).

- Abaixoalta pressão (50–100 MPa), a mistura é moldada emcilíndrico, quadrado, ou briquetes ovais.

- Nenhuma cola adicional é necessária se o carvão tiver propriedades de ligação natural suficientes.

EmMáquinas de Weiwa, nossomáquinas de briquetagem de casca de cocosão projetados paraalta eficiência, baixo consumo de energia, e desempenho durável.

6. Secando os briquetes

Os briquetes recém-prensados contêmalta umidade (10–20%)e deve ser seco paragarantir dureza e longa vida útil.

- Secagem Natural ao Sol: Lento, mas econômico (leva de 2 a 3 dias).

- Secagem Mecânica (Secador de ar quente): Mais rápido (6–12 horas) e mais controlado, garantindoníveis de umidade consistentes abaixo de 8%.

7. Embalagem & Armazenar

Depois de seco, os briquetes são:

- Resfriadoà temperatura ambiente.

- Embaladoem sacos ou sacos para armazenamento e distribuição.

- Armazenado em local secopara evitar a absorção de umidade.

Princípios de funcionamento da linha de produção de briquetes de carvão com casca de coco

O inteirolinha de produção opera em um fluxo sistemático, garantindoeficiência, qualidade, e desperdício mínimo.

Princípios Chave:

- Decomposição Térmica (Carbonização): Converte biomassa em carvão via pirólise controlada.

- Compressão Mecânica (Briquetting): Usa alta pressão para formar briquetes densos sem aglutinantes (ou com ligantes mínimos).

- Controle de umidade (Secagem): Garante que os briquetes sejam duros, durável, e duradouro.

NossoEquipamentos de máquinas Weiwaé projetado paraotimizar cada etapa, reduzindo o desperdício de energia e maximizando a produção.

Potencial de mercado & Oportunidades de negócios

Odemanda global por briquetes de carvão de casca de cocoestá crescendo rapidamente devido:

1. Alternativa de combustível ecológico

- Usado emfamílias, restaurantes, e indústriascomo umalternativa mais limpa à madeira ou carvão.

- Preferido paraTwys, mas smdítico, Shisha, e churrascosdevido à suaaroma e queimadura limpa.

2. Indústria de Carvão Ativado

- O carvão de casca de coco é ummatéria-prima principal para carvão ativado, usado emFiltração de água, Purificação do ar, e aplicações médicas.

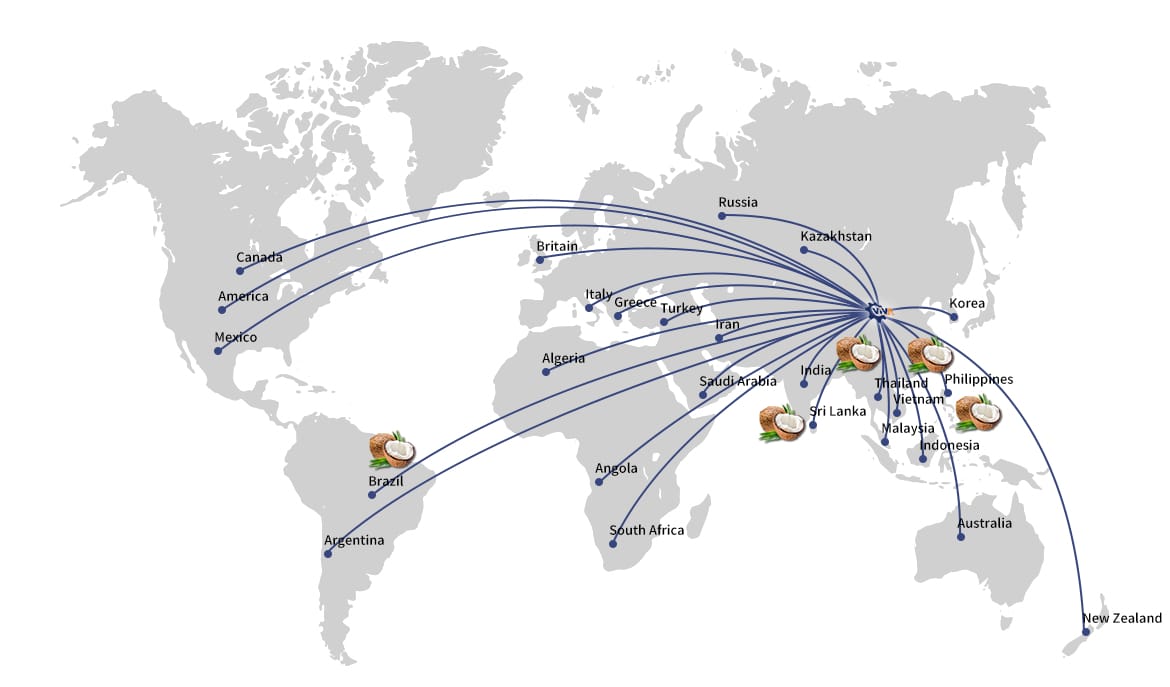

3. Potencial de exportação

- Países comoJapão, Coréia, Europa, E o Oriente MédioImportar briquetes de casca de coco de alta qualidade a granel.

4. Apoio Governamental & Tendências de Sustentabilidade

- Muitos governos promovemprojetos de energia de biomassa, oferecendosubsídios ou incentivos fiscaispara produtores de carvão.

Ao investir em umLinha de produção de briquete de carvão de casca de coco, os empreendedores podem aproveitarlucrativo, ecológico, e mercado de alta demanda.

Por que escolher máquinas Weiwa para sua linha de produção?

EmMáquinas de Weiwa, nós somos umfabricante líder de equipamentos de processamento de biomassa, especializado emlinhas de produção de briquetes de carvão de casca de coco. Veja por que somos sua melhor escolha:

✅Equipamento de alta qualidade– Nossocarbonizadores, trituradores, Briquette de máquinas, e secadoressão construídos paradurabilidade e eficiência.

✅Soluções personalizáveis – Nós projetamos linhas de produção chave na mãosob medida para sua escala de produção.

✅Tecnologia com Eficiência Energética – Nossas máquinas minimizam consumo de energia e emissões.

✅Experiência Global – Fornecemos equipamentos para sobre 50 países, garantindosuporte confiável e serviço pós-venda.

✅Preços competitivos– Obtermáquinas premium a preços diretos de fábricacomopções de pagamento flexíveis.

Comece seu negócio de briquetes de carvão com casca de coco com máquinas Weiwa

OLinha de produção de briquete de carvão de casca de cocoé umrentável, sustentável, e negócios sob demanda. Com o equipamento e processo certos, você pode converterdesperdiçar cascas de coco em briquetes de carvão de alto valorparamercados nacionais e internacionais.

Máquinas de Weiwafornececompleto, confiável, e soluções de produção eficientespara ajudá-lo a ter sucesso neste setor. Quer você seja umempresário de pequena escala ou um grande fabricante, nós temos oequipamento e experiência certospara apoiar seu empreendimento.

Contate-nos hojepara obter umconsulta gratuita, cotação, ou demonstração de equipamentopara o seuLinha de produção de briqueta de carvão de casca de coco.

Sobre Máquinas de Weiwa

Máquinas de Weiwaé umfabricante profissional de equipamentos de processamento de biomassa, especializado emmáquinas para fazer carvão, prensas de briquetagem, fornos de carbonização, e sistemas de secagem. Comanos de experiência e uma base global de clientes, estamos empenhados em fornecerinovador, energeticamente eficiente, e soluções econômicaspara a produção de energia sustentável.

Deixe-nos ajudá-lo a transformar cascas de coco em lucro - faça parceria com a Weiwa Machinery hoje mesmo!

WeChat

WeChat

+8613838093177

+8613838093177