Introdução

The demand for sustainable charcoal production is growing globally, E a Malásia não é exceção. Como líder em equipamentos de processamento de biomassa, Máquinas de Weiwa is proud to introduce our Forno de carbonização horizontal to the Malaysian market. This advanced technology offers an efficient, eco-friendly solution for converting wood into high-quality charcoal, meeting both industrial and commercial needs.

In this blog, we’ll explore how our forno de carbonização operates in Malaysian client sites, the benefits of horizontal carbonization, and the step-by-step process of how to make charcoal from wood.

Why Choose a Horizontal Carbonization Furnace?

1. Superior Design for Efficiency

Ao contrário dos fornos verticais tradicionais, Weiwa’s Forno de carbonização horizontal ensures uniform heat distribution, reducing energy waste and improving output consistency. Its horizontal structure allows for easier loading and unloading, making it ideal for large-scale production.

2. Eco-Friendly and Sustainable

Our furnace minimizes harmful emissions by utilizing a closed-loop carbonization system. This aligns with Malaysia’s push for greener industrial practices, reducing deforestation pressures by efficiently processing wood waste.

3. High-Quality Charcoal Output

The controlled carbonization process ensures that the final charcoal product has:Higher fixed carbon content,Lower ash residue and Consistent burn performance

This makes it perfect for applications in metallurgy, cooking fuel, and agricultural use.

How to Make Charcoal from Wood Using Weiwa’s Carbonization Furnace

Etapa 1: Preparing the Raw Material

The process begins with selecting suitable wood, such as coconut shells, madeira dura, or bamboo. The wood is dried and cut into uniform sizes to ensure even carbonization.

Etapa 2: Loading the Furnace

NossoForno de carbonização horizontal features a large loading capacity, allowing for bulk processing. The wood is evenly placed inside to prevent uneven burning.

Etapa 3: Controlled Carbonization

The furnace heats the wood in an oxygen-limited environment at temperatures between 400°C to 600°C. This pyrolysis process breaks down the wood into charcoal, alcatrão, and combustible gases, which can be reused as energy.

Etapa 4: Cooling and Discharge

Após carbonização, the charcoal is cooled systematically to prevent spontaneous combustion. The final product is then discharged, ready for packaging or further processing.

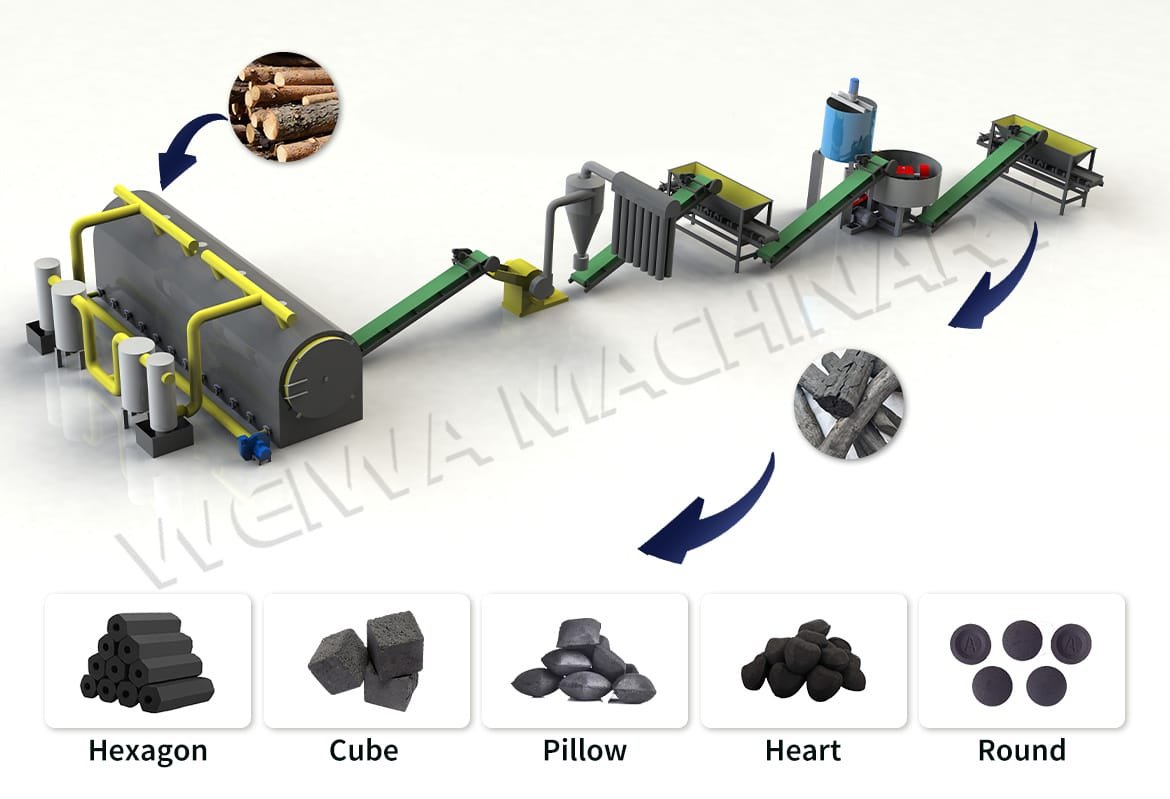

This is the 3D flowchart we customized for the client.

Weiwa’s Carbonization Furnace Client Success Stories in Malaysia

Malaysian clients have reported significant improvements in efficiency and product quality after adopting our Forno de carbonização horizontal. One palm oil waste processing plant saw a 30% increase in charcoal yield while reducing operational costs.

Key Benefits for Malaysian Industries:

- Reduced operational costs – Lower energy consumption compared to traditional kilns.

- Scalable production – Suitable for small workshops and large factories.

- Compliance with environmental regulations – Meets Malaysia’s strict emission standards.

Partner with Weiwa for Advanced Charcoal Solutions

Weiwa Machinery is committed to providing cutting-edge fornos de carbonização that enhance productivity and sustainability. Whether you’re in Malaysia or elsewhere, nossoForno de carbonização horizontal offers a reliable, efficient way to make charcoal from wood while minimizing environmental impact.

Sobre Weiwa Machinery

Weiwa Machinery is a leading manufacturer of equipamento de processamento de biomassa, specializing in carbonization furnaces, Briquette de máquinas, e sistemas de secagem. Com mais30 years of industry experience, we serve clients worldwide with innovative, energy-efficient solutions.

Contate-nos hoje to learn how our Forno de carbonização horizontal can transform your charcoal production process!

WhatsApp/Phone:008613838093177

E-mail:info@cjlmachinegroup.com

WeChat

WeChat

+8613838093177

+8613838093177