介绍

全球对可持续木炭生产的需求正在增长, 马来西亚也不例外. 作为生物质加工设备的领导者, WEIWA机械很自豪地介绍我们水平碳化炉 进军马来西亚市场. 这项先进技术提供了高效, 将木材转化为优质木炭的环保解决方案, 满足工业和商业需求.

在这个博客中, 我们将探索我们的碳化炉 在马来西亚客户网站运营, 卧式碳化的好处, 以及分步过程如何用木材制作木炭.

为什么选择卧式碳化炉?

1. 卓越的效率设计

与传统立式炉不同, 魏瓦的水平碳化炉确保热量分布均匀, 减少能源浪费并提高输出一致性. 卧式结构,装卸更方便, 使其成为大规模生产的理想选择.

2. 环保且可持续

我们的熔炉利用闭环碳化系统最大限度地减少有害排放. 这与马来西亚推动绿色工业实践相一致, 通过有效处理木材废料来减轻毁林压力.

3. 高品质木炭输出

受控的碳化过程确保最终的木炭产品具有:固定碳含量较高,较低的灰渣残留和一致的燃烧性能

这使其非常适合冶金应用, 烹饪燃料, 和农业用途.

如何使用威瓦的炭化炉从木材中制取木炭

步 1: 准备原料

该过程从选择合适的木材开始, 比如椰子壳, 硬木, 或竹子. 将木材干燥并切割成均匀尺寸以确保碳化均匀.

步 2: 装载炉子

我们的水平碳化炉 具有承载能力大的特点, 允许批量处理. 木材均匀放置在里面,防止燃烧不均匀.

步 3: 受控碳化

该炉在氧气有限的环境中以介于 之间的温度加热木材400°C 至 600°C. 这种热解过程将木材分解成木炭, 焦油, 和可燃气体, 可以作为能源重新利用.

步 4: 冷却及排气

碳化后, 木炭被系统冷却以防止自燃. 然后排出最终产品, 准备包装或进一步加工.

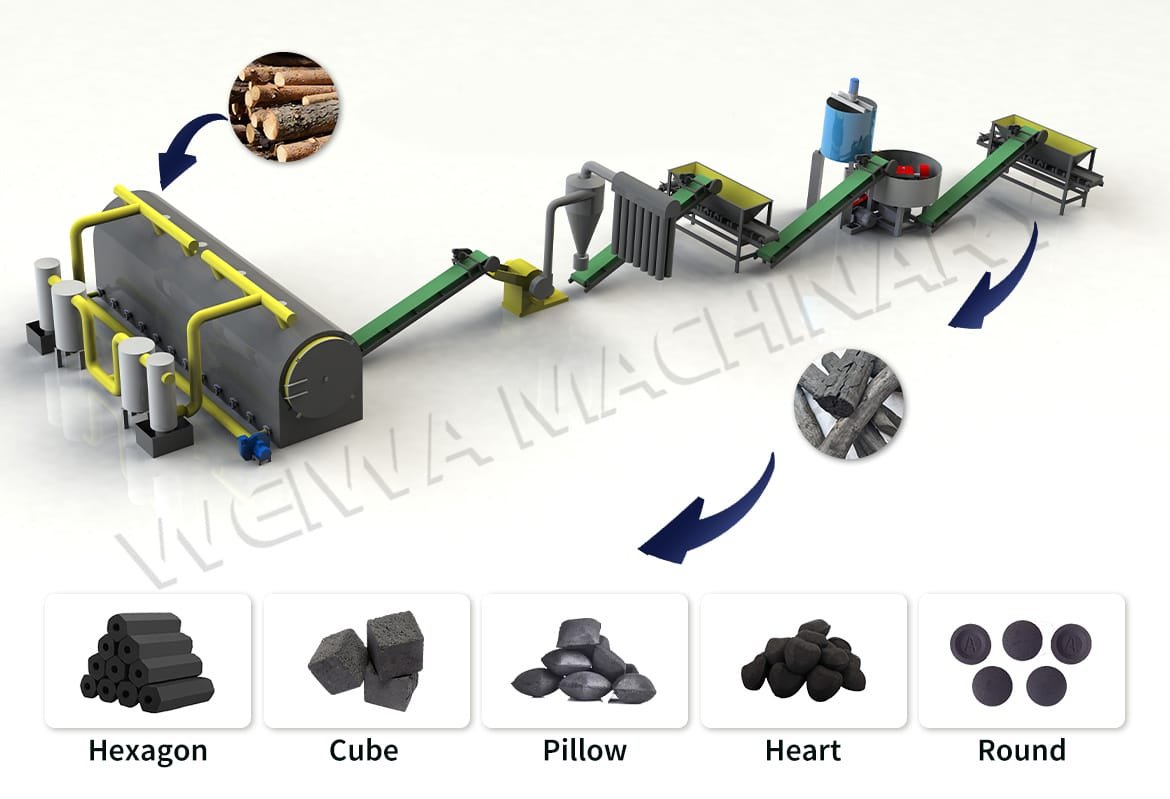

这是我们为客户定制的3D流程图.

威瓦炭化炉客户成功案例 在马来西亚

马来西亚客户表示,采用我们的产品后,效率和产品质量有了显着提高水平碳化炉. 一家棕榈油废物加工厂看到了30% 增加木炭产量同时降低运营成本.

马来西亚工业的主要好处:

- 降低运营成本 – 与传统窑炉相比能耗更低.

- 可规模化生产 – 适用于小型作坊和大型工厂.

- 遵守环境法规 – 符合马来西亚严格的排放标准.

与 Weiwa 合作提供先进木炭解决方案

威瓦机械致力于提供尖端碳化炉提高生产力和可持续性. 无论您在马来西亚还是其他地方, 我们的水平碳化炉 提供可靠的, 有效的方法用木头制作木炭同时最大限度地减少对环境的影响.

关于Weiwa机械

威瓦机械是领先的制造商生物质加工设备, 专业生产碳化炉, 机器煤球, 和干燥系统. 随着超过30 多年行业经验, 我们以创新的方式为全球客户提供服务, 节能解决方案.

立即联系我们了解我们如何水平碳化炉可以改变您的木炭生产过程!

WhatsApp/电话:008613838093177

电子邮件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177