位于沙特阿拉伯不断发展的工业格局的中心, 可持续性和资源效率日益成为优先事项, 威瓦机械是提供尖端解决方案的值得信赖的合作伙伴. 拥有三十多年制造液压机设备的专业知识, 最近,我们有幸为沙特阿拉伯客户进行了液压压球机的现场试运行.

The Rise of Hydraulic Briquette Technology in Saudi Arabia

Saudi Arabia’s Vision 2030 制定了雄心勃勃的目标,以实现石油以外的经济多元化, 强调可再生能源, 减少废物, 和可持续工业实践. 这些目标的交叉点在于生物质利用——液压煤球机正在成为这一领域的游戏规则改变者. 传统生物质处置方法, 比如露天焚烧, contribute to air pollution and squander valuable organic resources. 相比之下, hydraulic briquette presses convert agricultural residues, 林业废弃物, and municipal solid waste into dense, high-calorific briquettes that serve as clean alternatives to fossil fuels.

For Saudi Arabia, with its vast agricultural regions producing date palm fronds, 麦秆, and olive pits, alongside growing urban waste streams, hydraulic briquette technology offers a dual solution: mitigating environmental harm and creating a circular economy. Our hydraulic briquette machine, engineered for durability and precision, is designed to thrive in Saudi Arabia’s arid climate while maximizing output from local raw materials.

了解 液压压球机

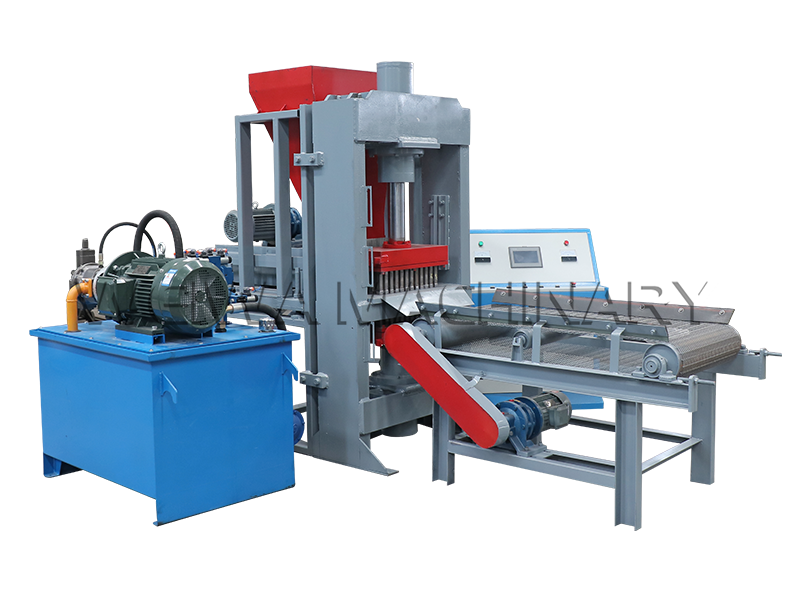

在Weiwa机械, our hydraulic press briquetting machine is a culmination of decades of R&D, tailored to meet diverse industrial needs. Unlike mechanical briquetters that rely on friction, hydraulic systems use pressurized fluid to generate immense force—up to thousands of tons—compressing loose biomass into uniform briquettes with densities exceeding 1.2 g/cm³. This process not only enhances combustion efficiency but also reduces volume by 70–80%, slashing transportation and storage costs.

The core components of our hydraulic briquette press include a robust frame, high-pressure hydraulic pump, precision-machined cylinders, and an automated control system. Raw materials are fed into a compression chamber, where the hydraulic system applies gradual pressure to expel air and bind particles via natural lignin (in biomass) or added binders (for certain wastes). The result is briquettes with low moisture content, consistent shape, and high calorific value—ideal for industrial boilers, cement kilns, and even household heating.

What sets our hydraulic briquette machine apart is its adaptability. Whether processing fibrous date palm waste or granular sawdust, the machine adjusts pressure and cycle times via intelligent controls, ensuring optimal briquette quality without material-specific modifications. For Saudi Arabia’s clients, this means minimal downtime when switching between feedstocks, a critical advantage in regions with seasonal agricultural cycles.

On-Site Trial in Saudi Arabia: Proving Performance in Harsh Conditions

To demonstrate the reliability of our hydraulic briquette press in real-world Saudi conditions, we recently conducted a trial at a client’s facility in Riyadh. The project focused on converting date palm fronds—an abundant byproduct of Saudi Arabia’s thriving date industry—into sellable fuel briquettes. Date palms cover over 1.2 million hectares in the kingdom, generating approximately 300,000 tons of fronds annually, most of which are discarded or burned, contributing to greenhouse gas emissions.

审前准备: Customization for Local Needs

Before the trial, our team collaborated closely with the client to assess their raw material characteristics and production goals. Date palm fronds are fibrous and lightweight, requiring specialized pre-processing to ensure uniform feeding into the hydraulic briquette machine. We recommended a integrated chipping and drying system to reduce frond size and moisture content from 40% to 15%—a threshold critical for effective compression. 此外, our engineers modified the machine’s feed hopper angle to prevent bridging, a common challenge with bulky biomass.

Trial Execution: Seamless Operation Under Scrutiny

Over five days, the hydraulic press briquetting machine processed 8 tons of dried date palm fronds daily, producing 2.5-ton batches of briquettes with diameters of 90mm and lengths of 150mm. 包括关键绩效指标:

- Pressure Consistency: The hydraulic system maintained stable pressure at 250 bar, ensuring briquettes met the client’s target density of 1.25 g/cm³.

- 能源效率: Power consumption averaged 45 kWh per ton of briquettes, 20% lower than comparable mechanical presses, thanks to our variable-speed pump technology.

- 耐用性: Operating in temperatures exceeding 38°C, the machine’s heat-dissipating components prevented overheating, with no downtime due to thermal stress.

The client was particularly impressed by the briquettes’ combustion properties: tests showed they burned cleaner than coal, 和 30% less ash residue and reduced sulfur emissions—aligning with Saudi Arabia’s strict environmental regulations.

The Untapped Potential of Hydraulic Briquette Machines in Saudi Arabia

The success of our trial underscores the vast opportunities for hydraulic briquette technology across Saudi Arabia’s industries. Here’s how our hydraulic briquette press can drive growth in key sectors:

农业: Turning Waste into Wealth

Saudi Arabia’s agricultural sector, though smaller than its oil industry, is a significant source of biomass. Beyond date palms, crops like alfalfa, sorghum, and barley generate substantial straw waste. By deploying hydraulic briquette machines, farms can transform these residues into a revenue stream, selling briquettes to poultry farms (for heating coops), bakeries, and small-scale power plants. 而且, reducing open-field straw burning will help Saudi Arabia meet its commitment to cut methane emissions by 30% by 2030 under the Global Methane Pledge.

Construction and Cement: A Cleaner Fuel Alternative

The construction boom fueled by Vision 2030 has increased demand for cement, a process that relies heavily on fossil fuels. Our hydraulic briquette press produces briquettes with calorific values of 4000–5000 kcal/kg—comparable to lignite coal but with lower carbon intensity. Cement manufacturers adopting these briquettes can reduce their reliance on imported coal, 降低运营成本, and enhance their ESG (环境的, 社会的, 治理) 证书. In trials with international cement firms, replacing 20% of coal with biomass briquettes cut CO₂ emissions by 15% without compromising kiln performance.

Municipal Solid Waste: Tackling Urban Challenges

With Saudi Arabia’s urban population projected to reach 40 million by 2030, managing municipal solid waste (MSW) is a pressing concern. Organic fractions of MSW, including food scraps and garden waste, are ideal feedstock for hydraulic briquette machines. By diverting these materials from landfills, cities can reduce methane emissions (a potent greenhouse gas 28 times more effective than CO₂ at trapping heat) and generate energy. Our machines are equipped with anti-corrosion features to handle mixed waste streams, making them suitable for urban waste management facilities.

Why Weiwa Machinery Is Your Ideal Partner for Hydraulic Briquette Solutions?

As a company with over thirty years of experience in hydraulic press manufacturing, Weiwa Machinery brings unmatched expertise to Saudi Arabia’s market. Our strengths lie in three pillars:

Decades of Engineering Excellence

Since our founding, we have refined hydraulic press technology to address global challenges, from European biomass markets to Southeast Asian waste-to-energy projects. Our hydraulic briquette machines are built with high-grade steel alloys, precision-machined components, and IP65-rated electrical systems, ensuring longevity even in dusty or humid environments like Saudi Arabia’s coastal regions.

Tailored Support Every Step of the Way

We understand that every client’s needs are unique. Our team offers end-to-end services, starting with free raw material analysis to determine optimal machine specifications. We provide customized design and layout planning for factory setups, ensuring seamless integration with existing infrastructure. Post-sale, our dedicated after-sales team—available 24/7 via phone and remote diagnostics—minimizes downtime, with spare parts stocked in regional hubs for rapid delivery.

Commitment to Client Success

Our recent trial in Saudi Arabia exemplifies our hands-on approach. Beyond testing the machine, we trained the client’s operators on maintenance best practices, shared data-driven insights to optimize briquette quality, and provided a roadmap for scaling production. This partnership-focused mindset has earned us long-term relationships with clients in over 50 国家.

Shaping a Greener Future Together

Saudi Arabia’s journey toward sustainability demands innovative technologies that balance economic viability with environmental stewardship. Our hydraulic press briquetting machine, proven in trials and engineered for local conditions, is poised to play a pivotal role in this transformation. By converting waste into wealth and fossil fuels into renewables, we empower businesses to thrive while advancing the kingdom’s green vision.

在Weiwa机械, we don’t just sell machines—we build partnerships. If you’re in Saudi Arabia or beyond, seeking a reliable hydraulic briquette press solution, 今天联系我们进行咨询. Let’s discuss your project, explore customization options, and chart a path to sustainable success.

关于 WEIWA机械

With over thirty years of experience in hydraulic press manufacturing, Weiwa Machinery specializes in designing and producing high-performance hydraulic press briquetting machines, 液压压块机, 及相关设备. Our professional after-sales team ensures prompt support, while our commitment to customized services and layout planning helps clients optimize their production facilities. Whether you need a hydraulic briquette machine for Saudi Arabia or other global markets, we welcome your inquiries and look forward to providing tailored solutions. Contact us now to start your journey toward efficient, eco-friendly briquetting.

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 电子邮件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177