介绍: 为什么木炭成型机对新西兰市场很重要

最近几年, 对可持续燃料解决方案的需求在全球范围内激增 - 新西兰也不例外. 随着人们越来越关注环保烧烤替代品, 农业废弃物利用, 和小规模木炭生产, the 木炭压球机已成为企业家和环保主义者的游戏规则改变者. 在WEIWA机械, 我们一直处于这场革命的最前沿, 提供高性能 球机器 (包括我们的旗舰木炭压球机) 适合不同市场.

上个月, 我们很高兴在中国工厂接待新西兰客户代表团. 他们的目标? 亲眼目睹我们如何烧烤木炭制造机 改变原材料 (像锯末, 椰子壳, 或生物质) 变成密集的, 高品质的木炭球 - 并测试满足其特定需求的样品.

为什么新西兰是木炭煤球解决方案的主要市场

可持续烧烤文化的兴起

新西兰人喜欢烧烤,但传统木炭往往会带来环境问题 (例如森林砍伐或高碳排放). 输入维瓦木炭压球机: 我们的设备生产环保木炭球来自农业废弃物 (例如。, 来自松树种植园的锯末, 太平洋进口椰子壳, 甚至果树修剪). 这些煤球燃烧起来更清洁, 更长, 并且是 100% 可再生能源——与新西兰的可持续发展目标完美契合.

当地小规模生产的需求

超越商业用途, 许多新西兰人正在探索DIY木炭生产 – 无论是农场废物管理还是利基市场 (像生态旅游旅馆或农民’ 市场). 我们的球按机专为灵活性而设计, 可生产5-20mm的木炭球,密度可调, 使其成为小型车间和大型工厂的理想选择.

访问: 新西兰客户在威娃的体验

当我们的新西兰客户到达时, 他们渴望看到三件事: (1) 机器是如何工作的, (2) 样品的质量, 和 (3) 操作起来有多简单. 以下是我们如何回答他们的问题:

现场演示: 从原料到炭球

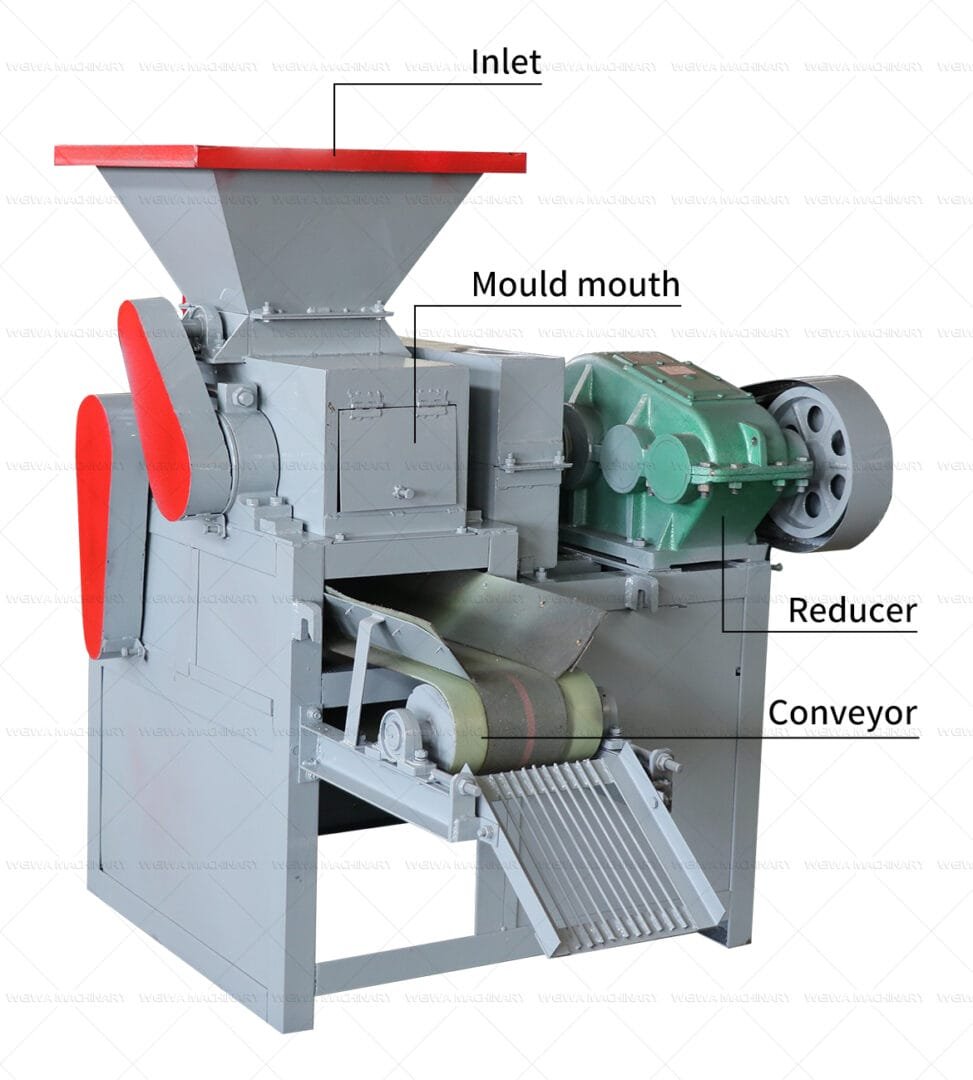

我们的团队从原材料组合开始 (木屑 + 用于装订的小活页夹, 尽管许多材料与我们先进的模具设计自然结合). 过程很简单:

- 进食: 原材料被装入我们的料斗中木炭压球机.

- 紧迫: 机器的液压系统 (或机械滚筒, 取决于型号) 将材料压缩成致密的球——大多数生物质类型不需要添加剂.

- 输出: 几分钟之内, 完美的圆形, 光滑的木炭球从模具中掉出, 准备干燥.

客户对此感到惊讶一致性和密度 – “这些看起来就像我们在商店里看到的优质木炭球, 但就在这里制作!其中一位指出.

样品测试: 耐用性, 燃烧时间, 和质量

我们提供预制样品 (由不同原料生产, 包括椰子壳和松木屑) 供客户测试. 主要观察结果:

- 耐用性: 球在处理时不会破碎——这是压制不良的煤球的常见问题.

- 燃烧性能: 点亮时, 它们均匀燃烧 2-3 小时 (比传统块炭更长), 烟雾或火花最少.

- 尺寸多样: 我们展示了8mm (用于水烟/水烟), 12毫米 (烧烤用), 和15毫米 (工业用) – 证明机器的适应性.

为什么威瓦的压球机在新西兰客户中脱颖而出

我们的客户留下的不仅仅是样品——他们对威娃有了信心技术, 支持, 和自定义. 这就是我们的与众不同之处:

1. 适用于多种材料的成熟技术

与普通印刷机不同, 我们的木炭压球机专为处理新西兰特有的原材料而设计:

- 松木屑 (当地林业资源丰富): 天然木质素含量高, 无需额外添加剂即可粘合良好.

- 椰子壳 (从太平洋邻国进口): 需要更高压力的硬质材料 - 我们机器的强化滚轮可以轻松处理它们.

- 农业废弃物 (例如。, 果皮, 玉米棒子): 灵活适合寻求废物升级利用的农场.

2. 可根据市场需求定制输出

新西兰企业有独特的要求——无论是精品烧烤品牌的小球还是商业用途的大球. 我们的机器提供:

- 压力可调 (控制密度和硬度).

- 模具互换 (生产不同尺寸的, 从5毫米到25毫米).

- 可选干燥系统 (适合需要一体化解决方案的客户).

3. 本地支持 & 售后服务

我们知道购买机器只是第一步. 这就是为什么我们提供:

- 现场培训 (在中国或通过视频通话为新西兰客户).

- 备件可用性 (快速运送到新西兰).

- 24/7 技术支援 (快速解决任何问题).

我们的木炭压块机背后的科学原理

对于那些对技术细节感兴趣的人: 我们的球按机使用的组合机械压力和材料物理制造耐用的煤球. 这是它的工作原理:

- 物质准备: 原始生物质干燥至含水量 8–12% (非常适合装订). 大多数材料不需要化学粘合剂——木材中的天然木质素充当胶水.

- 按压机构: 我们的液压或滚轮系统可施加 10-50 吨的压力 (取决于型号), 将材料压缩成致密的, 固体形式.

- 模具设计: 精密加工的模具确保形状均匀、表面光滑, 减少搬运过程中的破损.

结果? 木炭球90%+ 碳含量, 高热量价值, 和最少的灰分 – 非常适合家庭和商业用途.

新西兰客户的后续步骤

访问成功后, 一些新西兰客户表示有兴趣:

- 购买试验机 (测试当地原材料).

- 扩展到完整的生产线 (用于商业木炭企业).

- 合作定制模具 (对于独特的形状或尺寸).

我们目前正在与他们合作完成订单并提供培训——我们很高兴看到 Weiwa 的技术为新西兰的可持续能源未来做出贡献.

结论: 威瓦机械——您的木炭成型解决方案合作伙伴

在 WEIWA机械, 我们不只是销售机器 - 我们提供完整的解决方案变废为宝. 无论您是新西兰小农, 烧烤企业家, 或商业木炭生产商, 我们的球按机 (包括木炭压球机和烧烤木炭制造机) 旨在可靠地满足您的需求, 效率, 和自定义.

从我们的工厂车间到您的车间, 我们致力于帮助您取得成功. 准备好探索我们的设备如何为您服务? 立即联系我们 咨询或参观工厂 (虚拟或面对面)!

关于Weiwa机械

成立于 1990, WEIWA机械是一家领先的中国制造商,专门从事生物质加工设备, 包括木炭煤石机, 球机器, 和水烟/水烟木炭生产线. 随着超过 30 多年的经验, 我们服务过的客户包括新西兰, 澳大利亚, 非洲, 和东南亚, 提供具有本地化支持的高质量机器. 我们的使命? 帮助全球企业变废为宝, 环保产品.

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 电子邮件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177