Introduction to Charcoal Ball Production

Charcoal briquettes have become a popular alternative to traditional fuel due to their efficiency, 生态友好, 和成本效益. 木炭生产中使用的各种设备中, the 球木炭煤球机 (650 模型) stands out for its efficiency in shaping loose charcoal powder into compact, 高密度球. 在WEIWA机械, we specialize in providing reliable 木炭压球机 that cater to diverse industrial and commercial needs.

了解 650 Model Charcoal Ball Press Machine

什么是 球木炭煤球机?

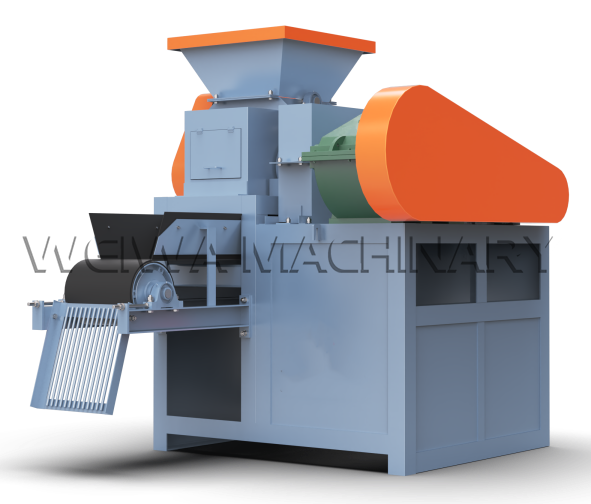

The 球木炭煤球机是一个mechanical press designed to compress 木炭粉, 煤尘, 或生物质材料进入坚硬的, 球形煤球. The 650 模型 is one of our most efficient presses, featuring a dual-roller (对辊) 系统 that ensures uniform pressure and high output.

Key Features of the 650 模型

- 高压 & 效率: The double roller mechanism ensures consistent briquette formation with minimal waste.

- 耐用的结构: 建立高级钢 to withstand continuous operation.

- Adjustable Moulds: Customize briquette size (usually 20-80mm) based on your requirements.

- 节能: Requires low power consumption while maintaining high productivity.

Common Applications

- 烧烤 & Grilling Fuel – Charcoal balls burn longer and produce less smoke.

- Industrial Heating – Used in furnaces, 锅炉, and metallurgical processes.

- Agricultural Use – Soil improvement and pest control.

- 家用燃料 – Clean-burning alternative to firewood.

如何 650 模型 木炭压球机 作品?

https://youtube.com/shorts/YLerBil2geE

原材料准备

Before operating the machine, ensure the 原料 (木炭粉, 煤尘, 或生物质)是:

- Dry (水分含量 < 12%) – Excess moisture reduces binding efficiency.

- Finely Ground – Particle size should be uniform for smooth pressing.

- Properly Mixed (if using binders) – Some materials require 淀粉, 糖蜜, 或粘土 as binders.

Machine Setup & Operation Steps

- 安装 & Alignment

- Place the machine on a stable, level surface.

- Ensure the rollers are correctly aligned to prevent uneven pressure.

- 喂料

- Use a vibrating feeder or manual feeding to supply material evenly.

- Avoid overfeeding, which can cause blockages.

- Adjusting Pressure & Roller Gap

- The 650 模型 allows adjustable pressure settings for different briquette densities.

- The roller gap should be set based on the desired briquette size.

- Starting the Machine

- Power on the machine and gradually increase speed to avoid sudden load.

- Monitor the output for consistency and adjust feeding rate if needed.

- 维护 & Troubleshooting

- Regularly clean the rollers to prevent material buildup.

- Lubricate moving parts to reduce wear and tear.

- Check for overheating – Excessive heat may indicate misalignment.

Why Choose Weiwa Machinery’s 650 模型?

1. 经过验证的专业知识 (30+ Years in Manufacturing)

与over three decades of experience, 威瓦机械精益求精木炭压球机 to meet global standards. 我们的650 模型专为设计耐用性, 效率, 和易用性.

2. 专业的售后支持

- 24/7 技术援助 – Our team is always ready to assist with troubleshooting.

- On-Site Training – We provide 手术 & 维护培训 for your staff.

- 定制解决方案 – Need a specific briquette size or material adaptation? We offer design drawings and layout planning.

3. 全球范围 & 定制

您是否需要一个standard 650 模型或afully customized solution, Weiwa Machinery ensures high-quality delivery and installation support worldwide.

立即开始使用Weiwa机械

The 650 Model Ball Charcoal Briquettes Machine是一个可靠的, high-efficiency solution for turning loose charcoal powder into profitable briquettes. 无论您在BBQ fuel production, 工业供暖, or agriculture, our machine delivers consistent performance with minimal operational challenges.

在WEIWA机械, 我们不只是销售设备——我们还提供完整的解决方案, 包括:

定制设计 & 规划

Professional Installation & 训练

Dedicated After-Sales Support

Contact us today for a quote or consultation and let us help you optimize your charcoal ball production line与我们的premium 650 model press machine.

关于 WEIWA机械

与30+ 多年的专业知识, WEIWA机械是领先的制造商木炭煤石机, 压球机, 和生物质设备. 我们的专业的售后团队, 定制解决方案, and design planning services确保全球客户无缝运营. Get in touch with us for inquiries and tailored machinery solutions today.

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 电子邮件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177