介绍: The Rising Demand for Hookah Charcoal

最近几年, the global demand for hookah (Shisha) 木炭已经激增, driven by the growing popularity of waterpipe smoking in the Middle East, 欧洲, and North America. Unlike traditional wood-based charcoal, hookah charcoal requires high density, 燃烧时间长, and minimal smoke, 制作煤基型煤 an increasingly viable alternative.

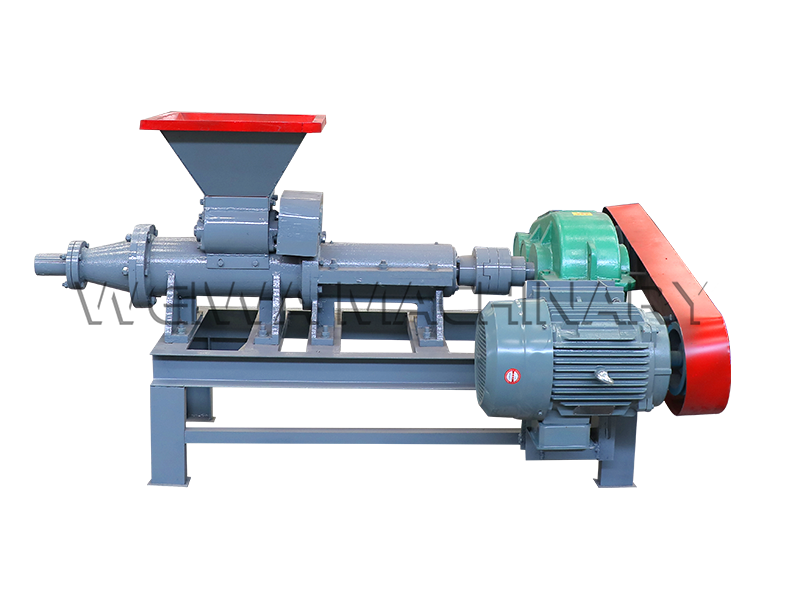

在WEIWA机械, we have upgraded our 煤棒机 (木炭挤压机)生产high-quality hookah charcoal at a lower production cost, leveraging binder-free or low-binder formulations for a cleaner burn.

Understanding the Charcoal Extruder Machine: 它如何工作

What is a Coal Rod Machine (木炭挤压机)?

a煤棒机, 也称为charcoal extruder or charcoal briquette machine, is a mechanical device that compresses powdered or granulated charcoal into dense rods or sticks使用high pressure and sometimes binders.

我们的upgraded coal rod machine is designed to:

- Produce uniform, high-density charcoal rods (ideal for hookah use).

- Operate efficiently with lower energy consumption.

- Use cost-effective raw materials (including coal fines, 生物量, or blends).

- Minimize waste and maximize output.

Why a Coal Rod Machine is Ideal for Hookah Charcoal?

Hookah charcoal requires:

✔高密度 (for longer burn time)

✔低烟 & 灰 (for a smoother smoking experience)

✔形状一致 & 尺寸 (for even heating)

我们的coal extruder machine achieves this by compressing charcoal powder into tightly bound rods, which can then be carbonized or directly used depending on the formulation.

Why Our Upgraded Coal Rod Machine is a Game-Changer

1. Lower Production Costs with Affordable Raw Materials

Traditional hookah charcoal is often made from coconut shells or hardwood, which are expensive and limited in supply. 我们的coal rod machine allows the use of cheaper coal fines or biomass blends, reducing raw material costs by up to 40%.

2. 更高效率 & 一致性

我们的newly optimized extruder确保:

- Uniform rod density (no cracking or breaking).

- 可调节的压力设置 for different charcoal types.

- Faster production rates 停机时间最短.

3. 环保 & Binder-Free Options

Unlike some charcoal briquette machines that rely on chemical binders, 我们的coal rod machine can produce binder-free or low-binder hookah charcoal, 制作它cleaner and more environmentally friendly.

4. Versatility in Production

While our machine is optimized for 水烟木炭, it can also produce:

- BBQ charcoal briquettes

- Industrial carbon rods

- Biomass fuel sticks

这个versatility makes it a smart investment for businesses looking to diversify their product lines.

The Science Behind Hookah Charcoal Production Using a Coal Rod Machine

How Coal-Based Hookah Charcoal is Made

- 原材料准备 – Coal fines, 淀粉 (optional binder), and additives are mixed.

- 挤压 – coal rod machine compresses the mixture into dense rods.

- 烘干 – The rods are dried to remove moisture.

- 碳化 (选修的) – For a purer burn, the rods can be carbonized in a kiln.

Why Coal-Based Hookah Charcoal is Gaining Popularity

- 燃烧时间更长 (compared to quick-lighting charcoal).

- No chemical additives (when using natural binders).

- Cost-effective for manufacturers.

我们的upgraded coal briquette machine ensures that these benefits are maximized while keeping production efficient and affordable.

市场潜力: Why Invest in Coal Rod Machine for Hookah Charcoal?

1. 全球需求不断增长

- The global hookah market is expected to reach $5 十亿美元 2030.

- Middle Eastern and European markets更喜欢高质量, 长燃烧木炭.

2. Competitive Advantage with Lower Costs

通过使用coal instead of coconut shells, manufacturers can reduce production costs while maintaining quality.

3. Sustainable & Scalable Production

我们的coal extruder machine 允许scalable production, whether you’re a small business or a large-scale manufacturer.

结论: Why Weiwa Machinery is Your Best Partner for Hookah Charcoal Production

在WEIWA机械, we have 超过 30 多年的经验在制造中木炭制造机, 包括煤棒机, 木炭挤压机, 和压块机. 我们的newly upgraded coal rod machine旨在maximize efficiency, 降低成本, and produce high-quality hookah charcoal.

我们提供什么:

专业的售后支持 – Our team ensures smooth operation.

定制解决方案 - 我们设计tailored machinery based on your needs.

场地规划 & Blueprint Services – We help optimize your production layout.

OEM/ODM Services – We can customize machines for your brand.

关于Weiwa机械

与超过 30 多年的专业知识 in the machinery industry, WEIWA机械专门研究木炭生产设备, 包括煤棒机, 木炭挤压机, 和压块机. 我们的专业的售后团队, 定制设计服务, 和on-site planning support ensure that every client gets the best solution for their needs.

Custom Machinery Design

专家技术支持

全球航运 & 安装

立即联系我们得到一个free quote or consultation for your charcoal production line.

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 电子邮件:info@cjlmachinegroup.com

微信

微信