介绍: Meeting Zimbabwe’s Charcoal Demand

非洲, 特别是津巴布韦, faces a growing need for eco-friendly fuel alternatives like sawdust charcoal briquettes. Traditional charcoal production depletes forests, while sawdust-based charcoal offers a renewable solution. 在WEIWA机械, we recently conducted a successful sawdust extruder and charcoal briquette machine trial for a Zimbabwean client, demonstrating our equipment’s efficiency in transforming waste sawdust into high-quality charcoal.

Why Sawdust Charcoal? The African Context

The Challenge of Traditional Charcoal in Zimbabwe

Zimbabwe, 像许多非洲国家一样, relies heavily on wood-derived charcoal for cooking and heating. 然而, this practice leads to deforestation, soil erosion, and carbon emissions. The government and environmentalists are pushing for sustainable alternatives, 和sawdust charcoal briquettes are emerging as a viable solution.

How Sawdust Charcoal Helps

- 废物利用: Sawdust from woodworking industries is usually discarded, but it can be compressed into 高密度煤球.

- Cleaner Burning: Sawdust charcoal produces less smoke and more heat比传统木炭.

- Economic Opportunity: Local entrepreneurs can profit from waste while meeting fuel demands sustainably.

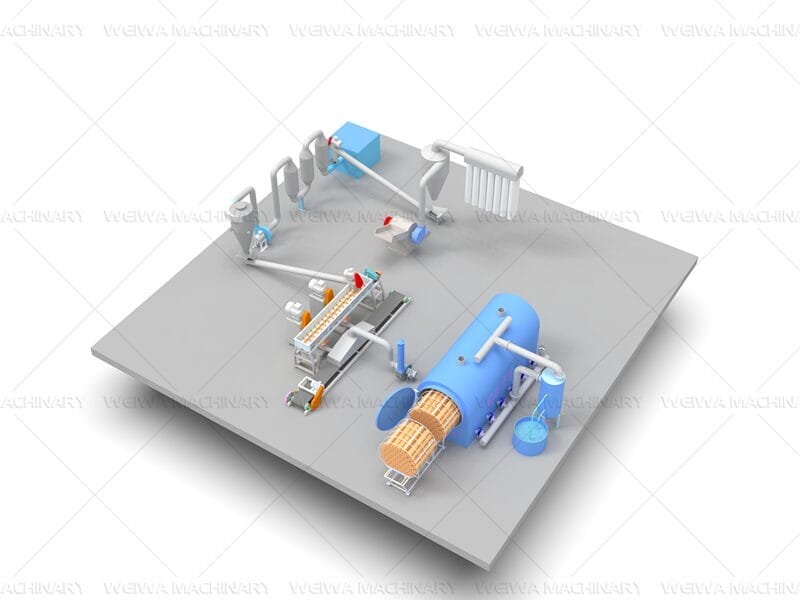

Weiwa’s Sawdust Charcoal Production Line: Key Machines

我们的sawdust-to-charcoal production line for Zimbabwe includes:

1. 木屑挤出机 (Sawduat Extrude Production Line)

The 锯末挤压机 compresses sawdust into 稠密, cylindrical blocks (called “煤球” 或者 “日志”) without binders. Our extruder in the trial processed 1-1.5 tons of sawdust per hour, 生产制服, high-density extrusions perfect for carbonization.

主要特点:

- 高压 & temperature control for optimal extrusion

- Durable steel construction for African operational conditions

- Adjustable output size to match client needs

2. 碳化炉 (Turning Extrusions into Charcoal)

After extrusion, the sawdust logs are carbonized in a kiln or furnace (provided by Weiwa or sourced locally). The trial showed that our extruded sawdust carbonizes faster than loose sawdust, resulting in 90% 木炭产量.

3. 木炭煤石机 (Optional Final Product Shaping)

For clients wanting briquettes instead of logs, 我们的木炭压球机 compresses carbonized sawdust into 制服, 市场就绪的煤球. The Zimbabwe trial produced smooth, 密集的煤球与高热量价值.

试验结果: What We Achieved in Zimbabwe

Machine Performance

- Extruder Efficiency: Processed 1.2 tons of sawdust/hour with minimal downtime.

- Carbonization Success: Extruded sawdust turned into 90% pure charcoal within 4-6 小时.

- Briquette Quality: Final briquettes had <5% breakage rate和high market appeal.

客户反馈

The Zimbabwean client was impressed by:

能耗低与传统方法相比

操作方便 (minimal training needed)

高品质木炭产量 (sold at premium prices)

Why Choose Weiwa Machinery for African Projects?

1. Proven Expertise in Sawdust Charcoal Machines

与多年的经验, 维瓦已提供charcoal production lines to Africa, 亚洲, 及以后, adapting machines to local conditions.

2. 可自定义的解决方案

您是否需要一个small-scale briquette machine or a full sawdust extruder line, we tailor equipment to your production goals.

3. 售后支持

We provide 安装指导, 训练, and spare parts to ensure smooth operations in Zimbabwe and other African regions.

结论: Sawdust Charcoal is the Future for Zimbabwe

The trial proved that Weiwa’s sawdust extruder and charcoal briquette machine can efficiently convert waste into profitable, eco-friendly fuel. For Zimbabwean entrepreneurs, 这意味着:

✔Sustainable income from sawdust waste

✔Cleaner, better charcoal for local markets

✔Reliable machinery from a trusted supplier (WEIWA机械)

If you’re in Zimbabwe or Africa and interested in sawdust charcoal production, contact Weiwa Machinery对于一个customized solution.

关于Weiwa机械

WEIWA机械 是领先的制造商biomass and charcoal production equipment, 专门研究锯末挤出机, 机器煤球, 和 complete carbonization lines. 与over three decades of experience, we serve clients in 非洲, 亚洲, 及以后, 提供耐用的, 高性能机器 适合当地需求. 我们的承诺质量, 创新, 和客户支持 makes us the preferred partner for sustainable fuel solutions.

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 电子邮件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177