介绍: 连续炭化技术的演变

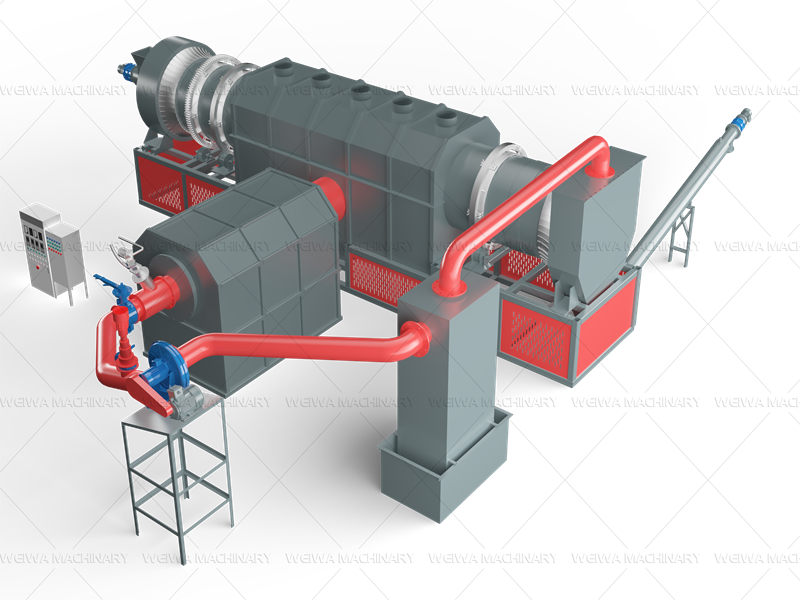

在不断发展的世界生物炭和木炭生产, 效率, 能量回收, 环境合规性不再是可选的,而是必不可少的. 在WEIWA机械, 我们已经花费了超过30 年 完善我们的碳化解决方案, 和我们的带二次燃烧室的新型连续式炭化炉代表着下一次飞跃。.

为什么连续式碳化炉是行业标准

连续碳化相对于间歇式处理的优势

传统间歇式碳化炉 需要频繁停机装卸, 导致能源利用效率低下,生产速度缓慢. 相比之下, 连续碳化炉就像我们允许的不间断运行, 确保稳定的产量和最大化的生产力.

我们的连续碳化炉 专为:

- 高通量 (适合大规模运营)

- 温度控制稳定 (确保一致的碳化质量)

- 最少的人工干预 (降低劳动力成本)

但真正让我们最新型号与众不同的是集成二次燃烧室——游戏规则的改变者能源效率和排放控制.

二次燃烧室改造连续式炭化炉

二次燃烧室的工作原理

The 二次燃烧室 (超临界碳化物)是我们升级后的连续碳化炉的核心. 这是它的工作原理:

- 余热回收 – 初级碳化过程产生高温烟气 富含未燃烧的挥发性化合物. 而不是让这股热量散去, 我们的SCC 捕获并重新燃烧这些气体于800–1200°C, 确保完全燃烧.

- 能源回收 – 回收的热量回馈至炭化炉, 减少外部燃料消耗 (例如天然气或煤炭) 通过高达 30-50%.

- 排放净化 – SCC 燃烧掉有害污染物 (像一氧化碳, 甲烷, 和颗粒物), 确保最终废气符合严格的环保标准.

这意味着降低运营成本, 减少碳足迹, 并遵守全球排放法规.

为什么二次燃烧室可以延长炉子寿命

直接暴露于高温火焰是传统炭化炉最大的磨损因素之一. 我们的SCC充当缓冲器, 防止直接接触火焰与主炉和显着延长其耐用性.

此外, 通过预净化废气, the SCC 减少腐蚀和污垢炉内, 导致:

- 减少维护停机次数

- 设备使用寿命更长

- 降低维修成本

如何操作 连续式碳化炉 二次燃烧室

在WEIWA机械, 我们不只是销售设备——我们还确保它完美满足您的特定需求. 这就是我们提供的原因全面的现场测试和试运行服务为了我们带二次燃烧室的连续式炭化炉, 给你100% 购买前的信心.

为什么试运行对于碳化设备很重要

碳化是一种高风险过程—温度控制, 原料相容性, 排放管理必须完美优化. 我们的试用计划可以让您:

- 验证实际性能的二燃室热回收及排放净化根据您的具体情况.

- 测试不同的生物质原料 (木屑, 椰子壳, 稻壳, ETC。) 查看熔炉如何适应您的原材料.

- 直接衡量节能效果通过监测燃料消耗减少情况 (通常30–50%与我们的 SCC).

- 遵守排放合规性符合当地法规, 确保安装过程中零意外.

我们的试用流程如何运作

环境效益: 更清洁的排放 & 碳信用额

会议 & 排放超标

世界各地的政府和行业正在收紧政策碳排放法规. 我们的二次燃烧室确保:

- 公司 (一氧化碳) 水平被最小化

- 颗粒物 (PM2.5/PM10) 大幅减少

- 挥发性有机化合物 (挥发性有机化合物) 被有效地烧掉

这使得我们的连续碳化炉符合欧盟标准, 我们, 和亚洲环境标准, 帮助客户避免罚款并获得监管部门批准.

赚取碳信用额 & 提高可持续性

由减少排放并提高能源效率, 我们的熔炉帮助生产商有资格获得碳信用额 在类似的程序下:

- 联合国气候变化框架公约 (京都议定书 & 巴黎协定)

- REDD+ (减少森林砍伐造成的排放 & 森林退化)

- 自愿碳市场

这转化为额外的收入来源对于优先考虑的生物炭和木炭制造商绿色生产.

为什么选择 WEIWA机械?

与超过 30 多年的专业知识在碳化, 生物炭, 和木炭机械, WEIWA机械是可持续工业解决方案领域值得信赖的品牌.

我们提供什么:

定制设计 & 规划 – 我们量身定制连续碳化炉 满足您的生产需求, 包括网站布局和工作流程优化.

专业的售后支持 - 我们的专门的技术团队提供安装指导, 故障排除, 和维护培训.

久经考验的可靠性 – 我们的熔炉是在现实条件下进行测试, 确保性能耐用,产量高.

无论您是一个小型生物炭生产商或大型木炭制造商, 威娃机械拥有适合您的解决方案.

碳化的未来就在这里

The 带二次燃烧室的新型连续式炭化炉来自WEIWA机械不仅仅是升级,更是革命. 由回收余热, 净化排放, 并延长设备寿命, 它提供了:

✔降低运营成本

✔更高的生产效率

✔更好的环境合规性

✔获得碳信用额的机会

如果您准备好升级您的碳化工艺, 立即联系威瓦机械对于一个免费咨询, 定制设计, 或参观工厂.

关于Weiwa机械

与30+ 多年的经验在制造中碳化炉, 生物炭机, 和木炭生产设备, WEIWA机械是全球领先的可持续工业解决方案. 我们的专业的售后团队, 定制设计, 和可靠的性能 使我们成为全球客户的首选.

请立即联系我们获取报价或技术咨询!

- 暴民:+8613838093177

- WhatsApp:+8613838093177

- 电子邮件:info@cjlmachinegroup.com

微信

微信

+8613838093177

+8613838093177